57

EN

• Make all the desired tweaks in the plugin („6.5.1 Explanation of the Autoleveler CA-Plugin“).

- Number of scanning points in X- and Y-direction

- Tool Z Offset

- Manual or Auto Zero

- Settings

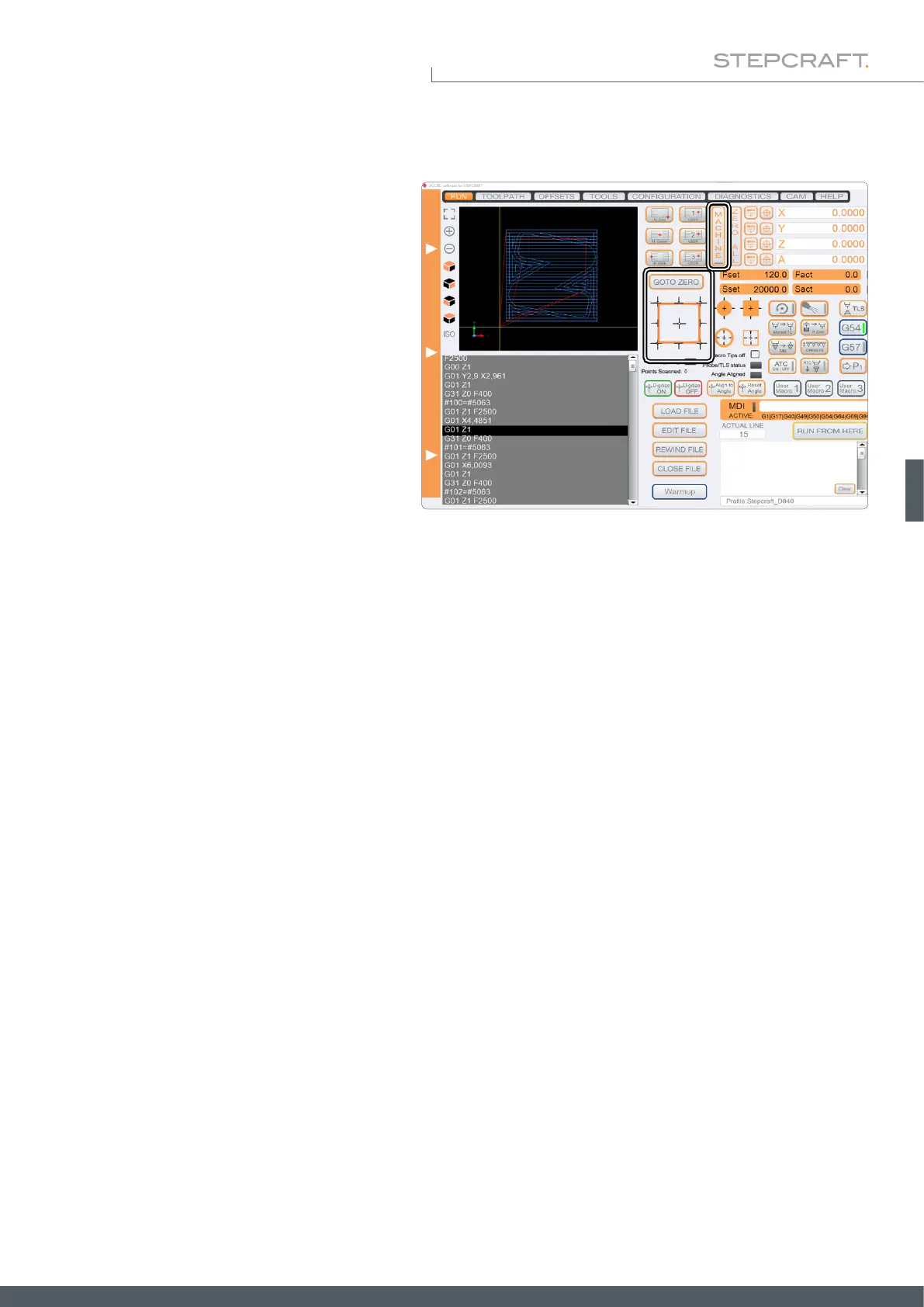

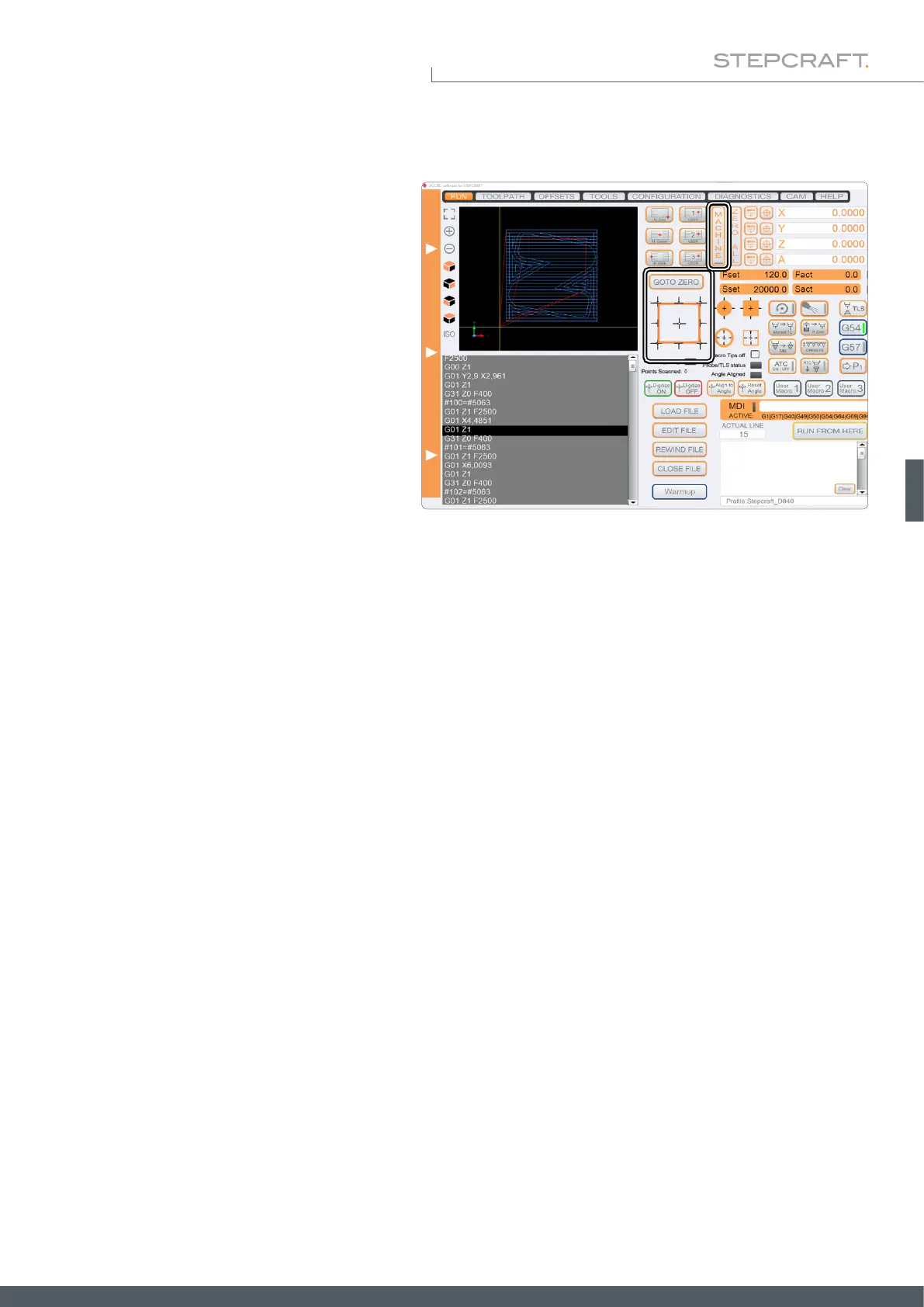

• Click Create GCode and send to UCCNC. It

may take some time to load the program into

UCCNC. In particular, a high number of probe

points increases the loading time.

• Use the contour probing macros to nd the X-,

Y- and Z-zero points, and then click Goto Zero.

• Start the milling program with Cycle Start. The surface is now scanned. After this process has been completed, the

milling program pauses. Take note of the current machine coordinates.

• Use this pause in the milling program to insert your tool. Manual control of UCCNC is still possible. Use the manual

control to set the Z-zero point with the tool. Move back to the starting position where the program was paused.

• Continue the process by clicking Cycle Start.

6.5.3 Scanning a Surface ("Create")

This application uses the 3D probe to scan a 3-dimensional surface. A multitude of measurements results in a three-di-

mensional point cloud, in which each point stands for a coordinate. From this cloud an object can be created for further

use. To utilize this function you need the following software:

• UCCNC-Plugin Autoleveler CA.

• A CAD / CAM software like Vectric VCarve or AutoDesk Fusion 360.

• A software like MeshLab to process the point cloud.

To scan an object, follow these steps:

Prepare your workpiece by xing it with a method of your choice. It is especially recommended for this application to use

a vise (such as item 12378 centering vise CV-140), double-sided tape (item 12482 adhesive sheet) or a vacuum table.

The advantage of these methods, is that the workpiece surface remains free. The next two chapters describe this process

once using VCarve and Fusion 360.

Loading...

Loading...