22

03.11

Strapex SMA 30

7 OPERATING INSTRUCTIONS

7.3 START STRAPPING

Prerequisites

– Machine is connected to the mains supply. Power

supply according to identifi cation plate.

– Both locking wheels locked.

– Strap coil has been installed and strap feed is

performed (see Chapter 6.2).

– Turn Main switch (3/1) to position “1“.

The warming-up time for the heating element

is about 20 seconds.

– Check strap tension, if necessary adjust it (see

Chapter 7.1)

– Select strapping operation manual or automatic (see

Chapter 7.2).

– Place the goods to be strapped (8/1) in the centre

of the machine on the table plate. Trigger strapping

with the foot pedal (8/2) (depending on mode of

operation). The strap will now be passed around the

package, tensioned, welded and cut off, then new

strap will be fed into the magazine.

– Remove the package.

– Check the seal (see chapter 7.4).

7.1 ADJUSTING STRAP TENSION

– Turn main switch (3/1) to position ”1“.

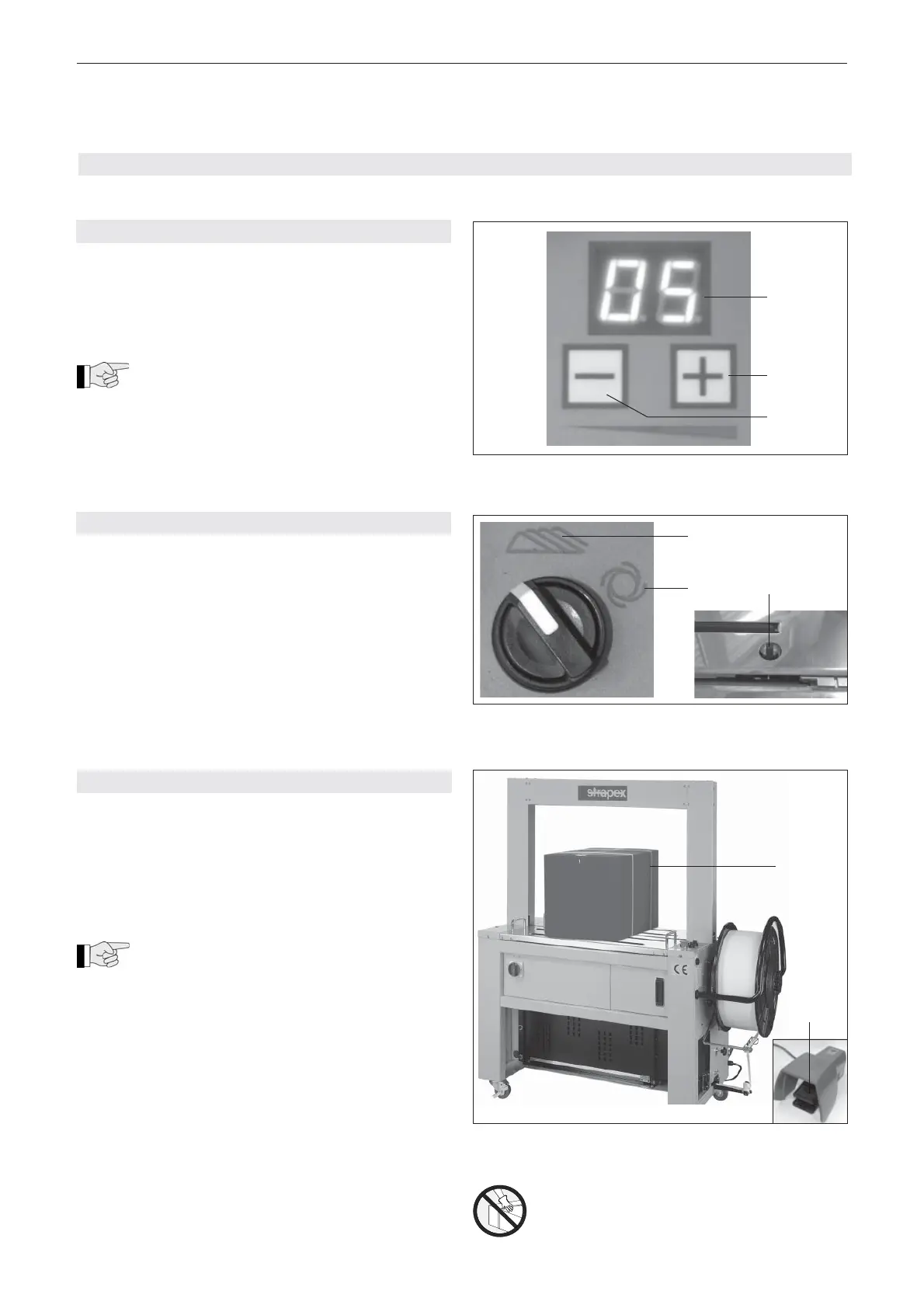

– Press ”Strap tension weaker“ (6/3) or ”Strap

tension stronger“ (6/2) buttons until required

value is shown on the ”Strap tension“ digital dis-

play (6/1).

The strap tension can be set in a range from

50–450 N.

Digital display Strap tension

0 approx. 50 N

5 approx. 150 N

10 approx. 250 N

20 approx. 450 N

7.2 SELECTOR SWITCH MANUAL / AUTOMATIC

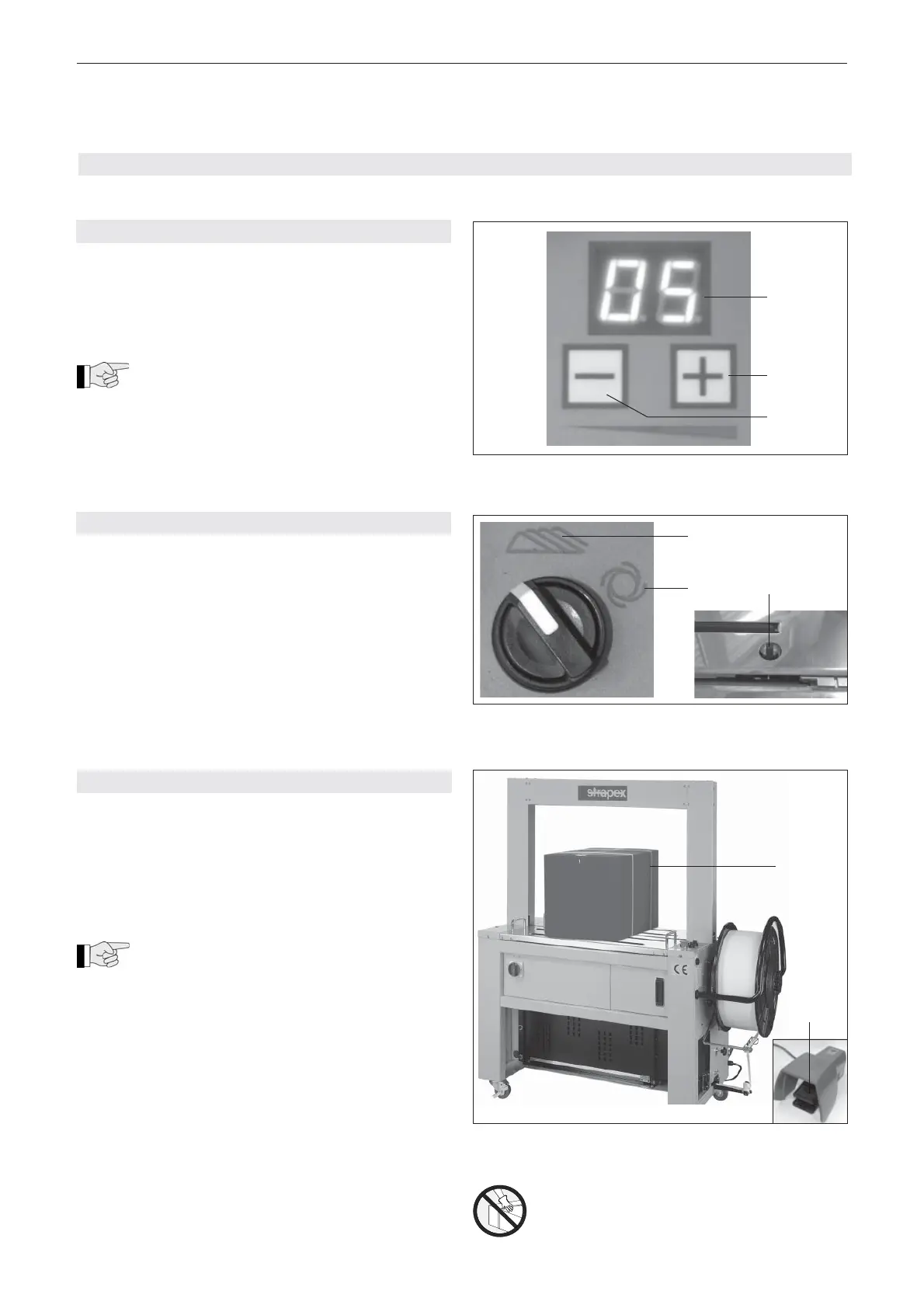

Manual operation (7/1):

Strapping is started using the start button (3/4) or foot

pedal (3/11) in this position.

Automatic operation (7/2):

In this position, strapping is started using the table

switch (7/3). If the table switch is covered by a packa-

ge, another strapping will start automatically.

1

2

3

1

2

Fig. 6

Fig. 7

3

Caution:

Only strap packed goods!

Do not put hands or other parts of the body

between the strap and the package during

the strapping process.

Fig. 8

1

2

Loading...

Loading...