26

03.11

Strapex SMA 30

9.4 SET DISTANCE BETWEEN TRANSPORT

AND PRESSURE ROLLER

The distance between the transport and

pressure roller is adjusted to strap thickness

of 0.55-0.65 mm. If the thickness varies, the strap

feed may not function correctly. The distance must be

set as following:

– Turn main switch (3/1) to position ”1“.

– Press the ”Reset” button (3/6) to move the machine

to its initial position.

– Insert strap to be used between transport and

pressure rollers.

– Loosen two cylinder screws (14/3), hold right clam-

ping lever (14/4) in position. Now the guide shaft

(14/5) can be turned by hand until the clearance

between torsion spring (14/2) and threaded bolt

(14/1) is about 1 mm.

– Tighten cyclinder screws (14/3) again.

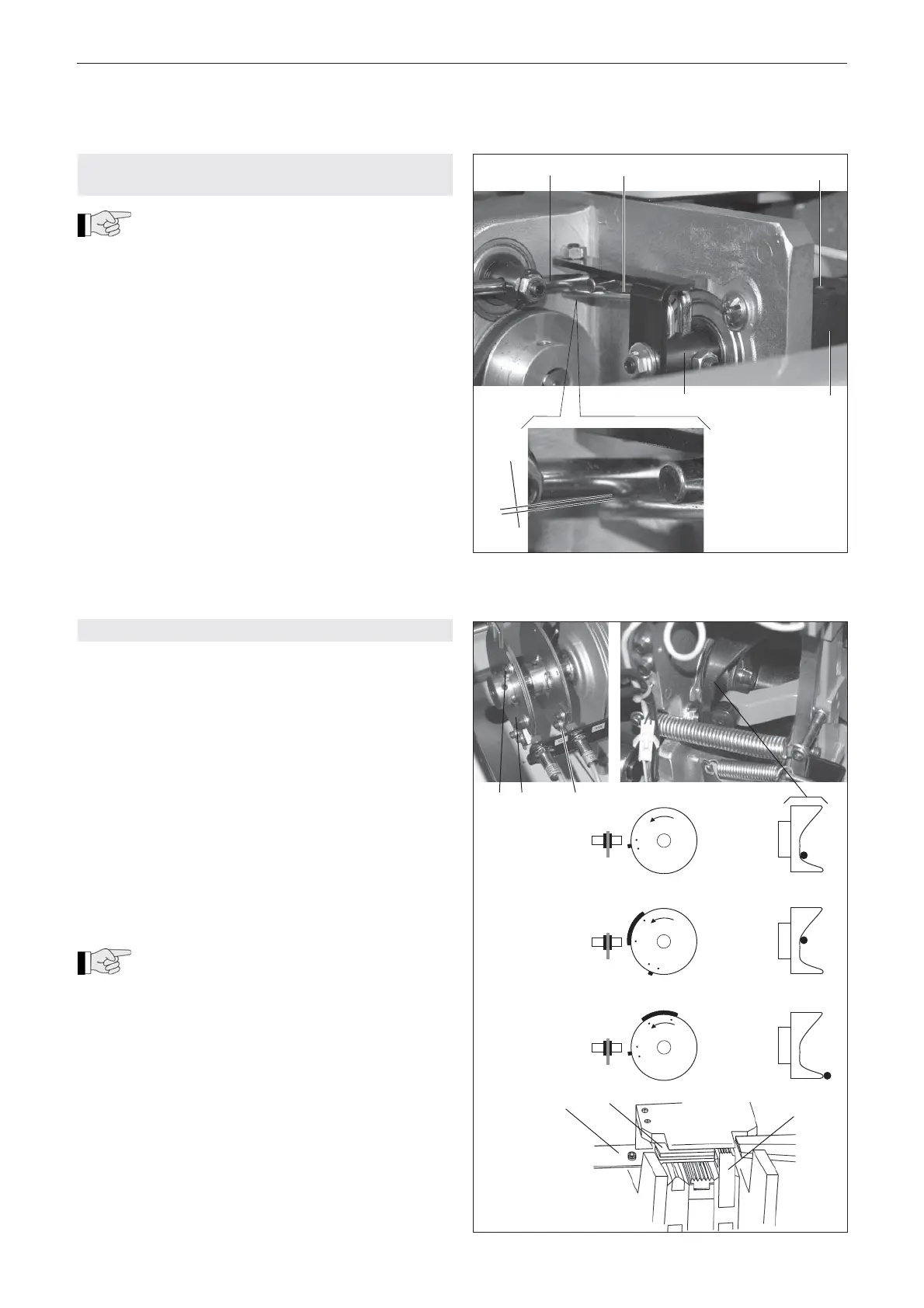

Fig. 14

1 2 3

4 5

1 mm

9.5 ADJUST LIMIT SWITCHES (CONTROL CAMES)

Initial position

The setting ”Initial position” is performed by limit switch

S48.

– Turn aggregate on drive belt of motor M23 by hand

so that the cam disk turns in direction of arrow (see

Fig. 15). Turn aggregate so that the radial cam is in

position A. Loosen two screws and turn cam element

(15/3) so that the cam is directly poitioned below the

limit switch S48 (see Fig. 15).

Strap take up

The setting ”Strap take up” is performed by limit switch

S39. (cam disk 15/2).

– Turn aggregate so that the radial cam is in position

B. Turn cam disk (15/2) so that the cam has directly

passed the limit switch S39 (see Fig. 15).

During this cycle the right-hand press unit

(15/4) moves up and clamps the strap. The

slide plate (15/5) moves backwards and the guide fl ap

(15/6) is opened.

Strap feed

The setting ”Strap feed” is performed by limit switch

S39. (cam disk 15/1).

– Turn aggregate so that the radial cam is in position

C. Turn cam disk (15/1) so that the cam has directly

passed the limit switch S39 (see Fig. 15).

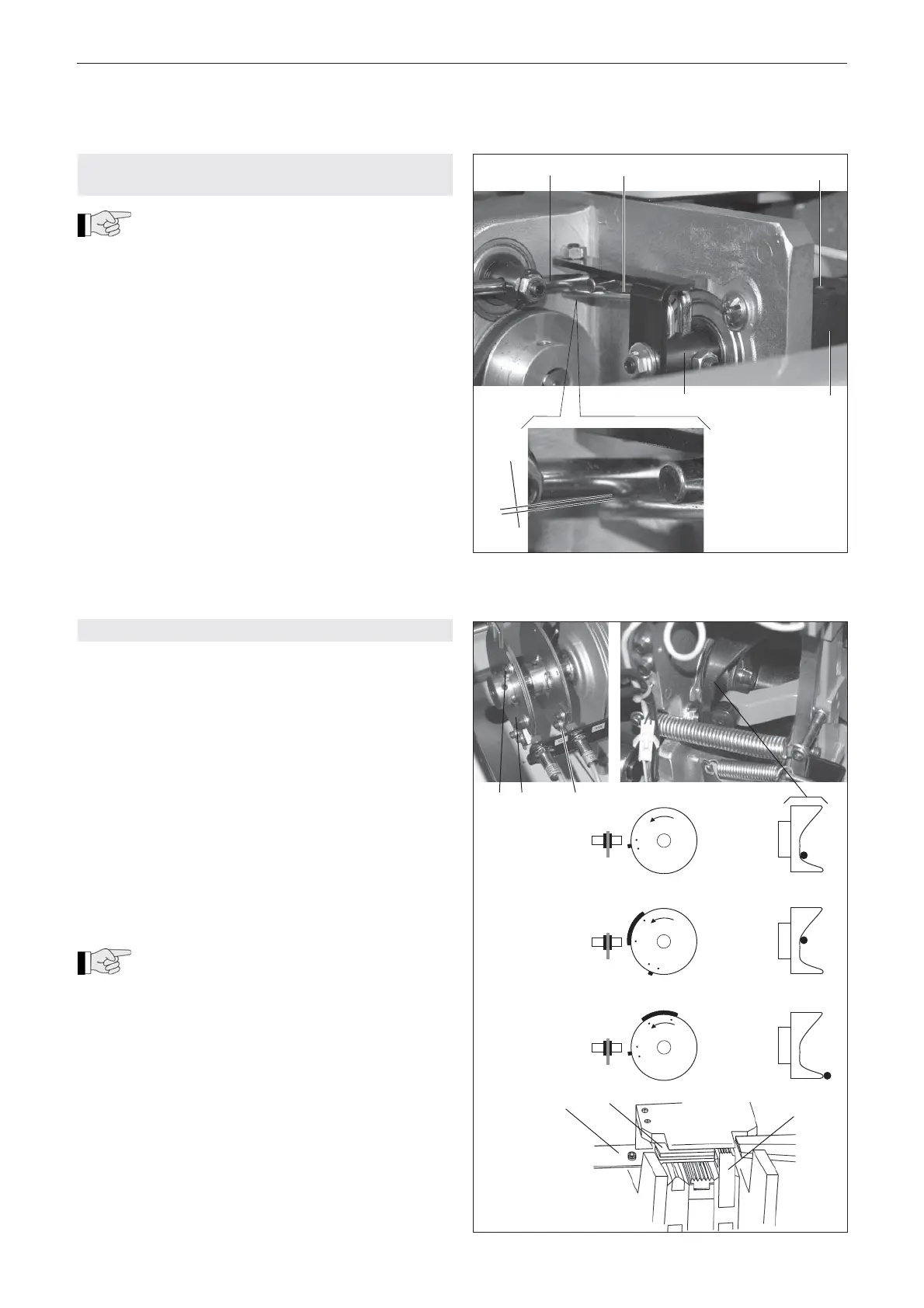

Initial position

Strap take up

Strap feed

S48

S39

S39

A

1 2 3

B

C

4

5

6

Fig. 15

Loading...

Loading...