46 BA_KA-ED_A22_190313_en.doc

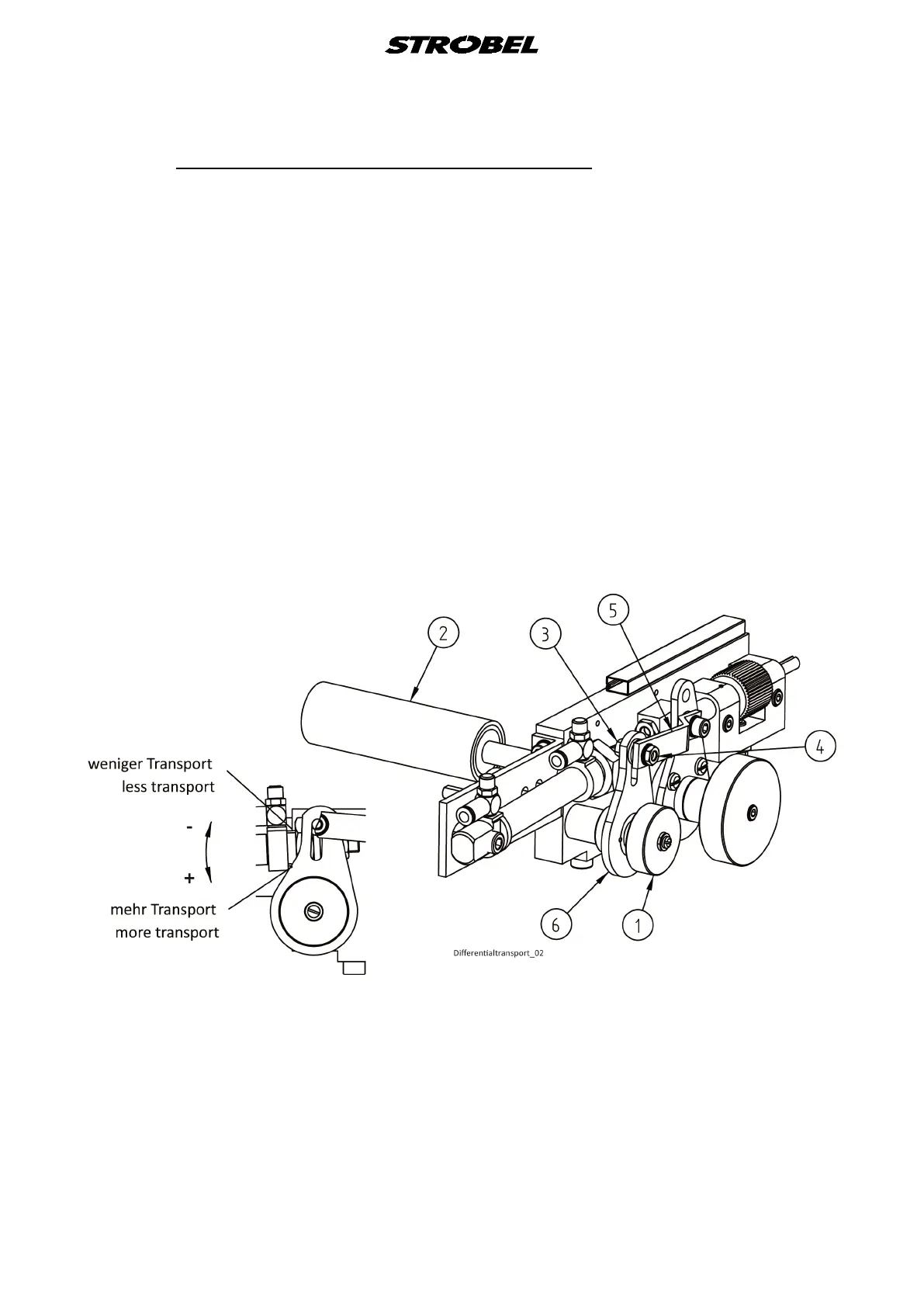

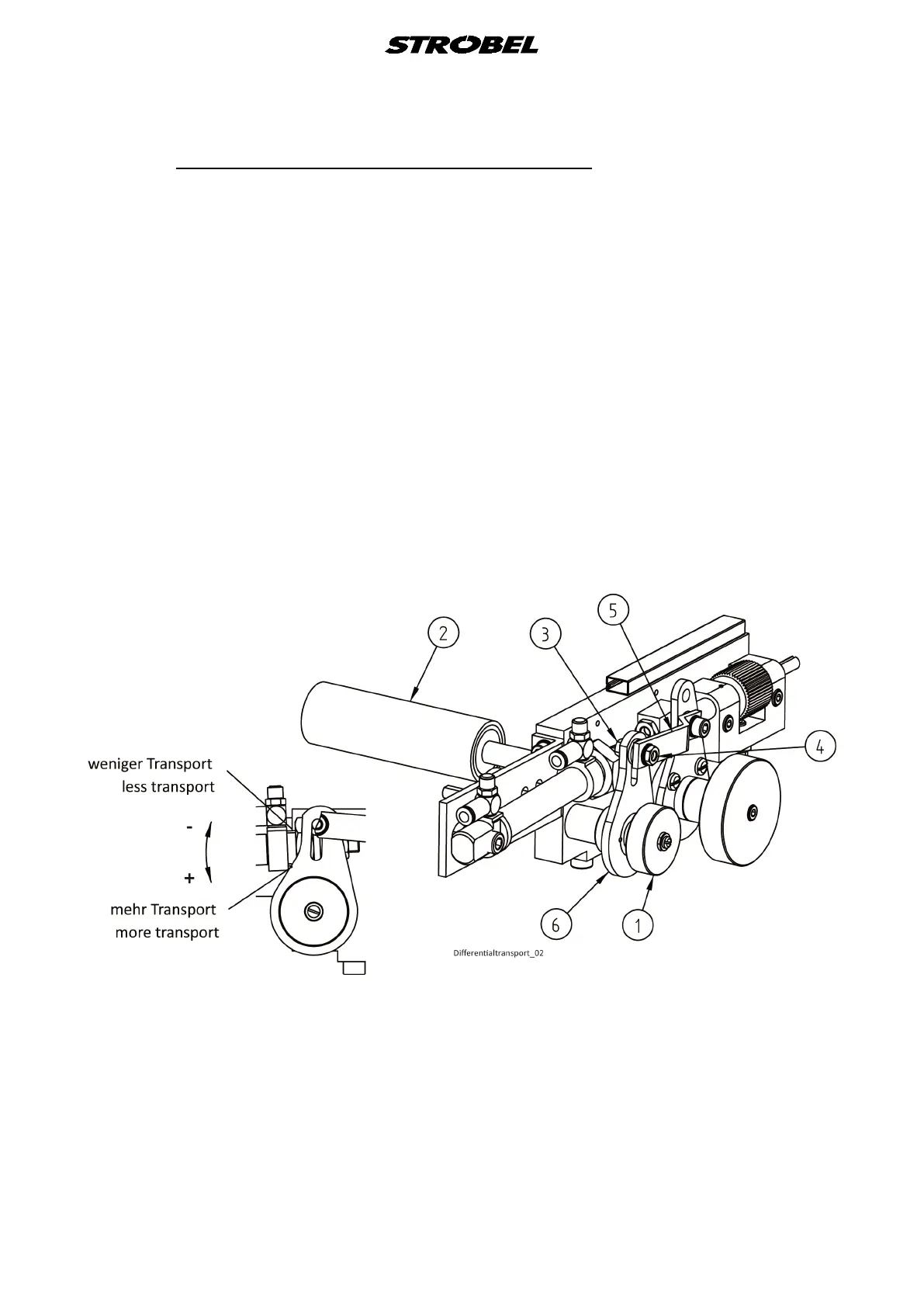

5.9.2 Rear differential transport drive (Fig. 27)

We offer two setting options for use with various materials:

The different rotational speeds of the nip roller are required to sew together different

material combinations.

Rollers are powered:

- Use machine knob (1) to connect the drive to the roller (2) (turn clockwise).

- Unscrew hexagonal nut (3) and hexagonal nut (4) to set lug (5) in the slotted

hole with freewheel lever (6). It is factory preset at the centre of the middle hole

(neutral speed of nip roller). When fastening below in the elongated hole, more

differential transport; when fastening above in the elongated hole, less

differential transport.

Rollers are not mechanically powered:

- Unscrew machine knob by turning anticlockwise and the roller turns with the

material.

Fig. 27

Loading...

Loading...