US-26

DE

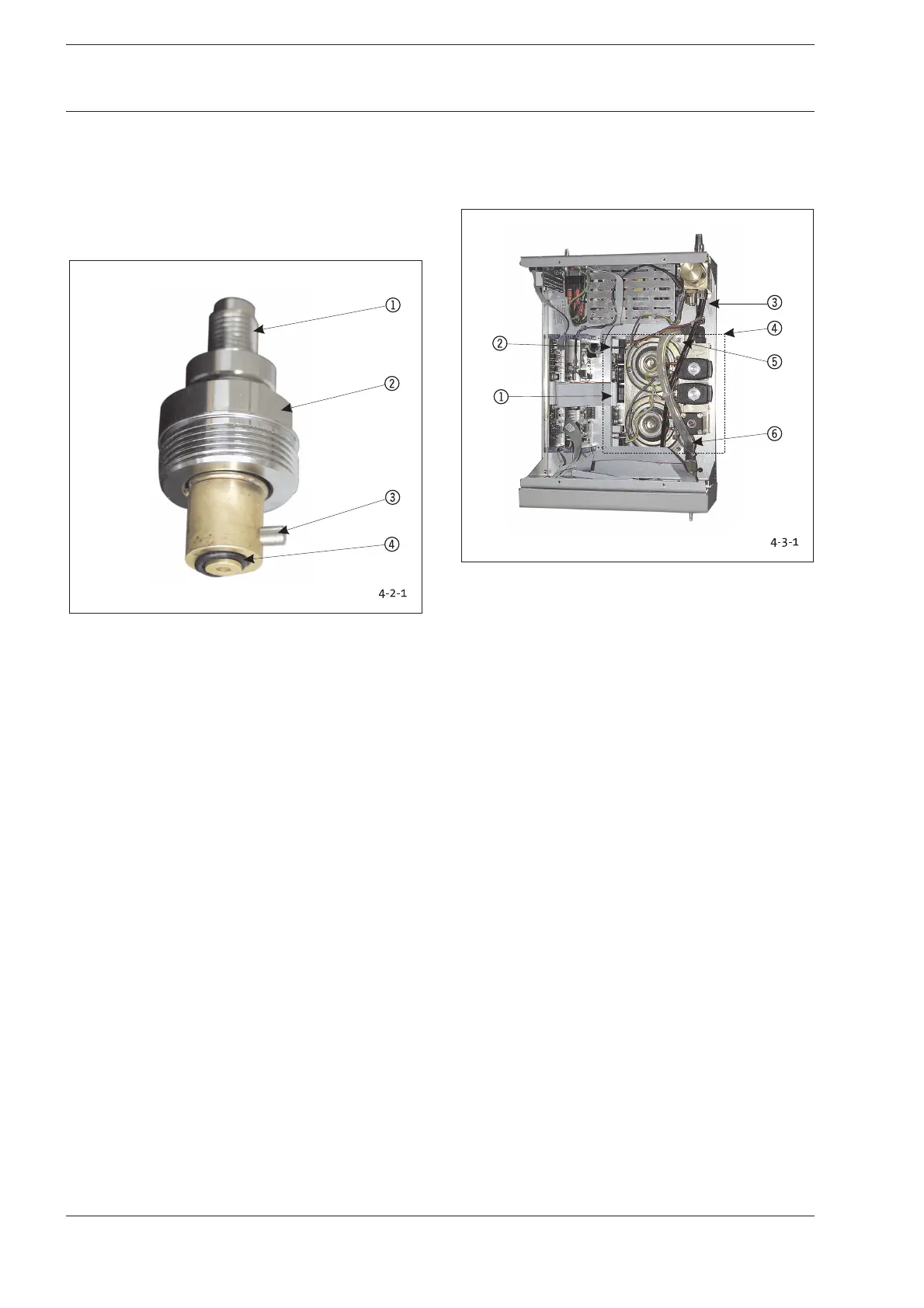

4-2 Gas Connection

The gas connection consists of the following:

Supply-specific connection adapter completely installed

with:

Screw Unions SW 24

O-Ring on Face

Fig. 4-2-1: CO2 Gas Connection

1 Gas Supply Connection

2 Flat SW 24

3 Anti-Twist Stop

4 O-Ring Seal

Replace elements in case of defective, non-sealing pressure

connections, flow-reducing filter soiling, and if operational

functionality is reduced.

1. Use SW 24 adjustable wrench to Unscrew rear plate

screws.

2. Make sure O-ring remains in place when removing

component.

3. Reverse instructions to install elements. Make sure anti-

twist stop is properly inserted when replacing gas

connection!

Conduct the following tests after replacing modules or

components:

1. High pressure level test (Item 2-3).

2. Flow volume test (Chapter 2-6).

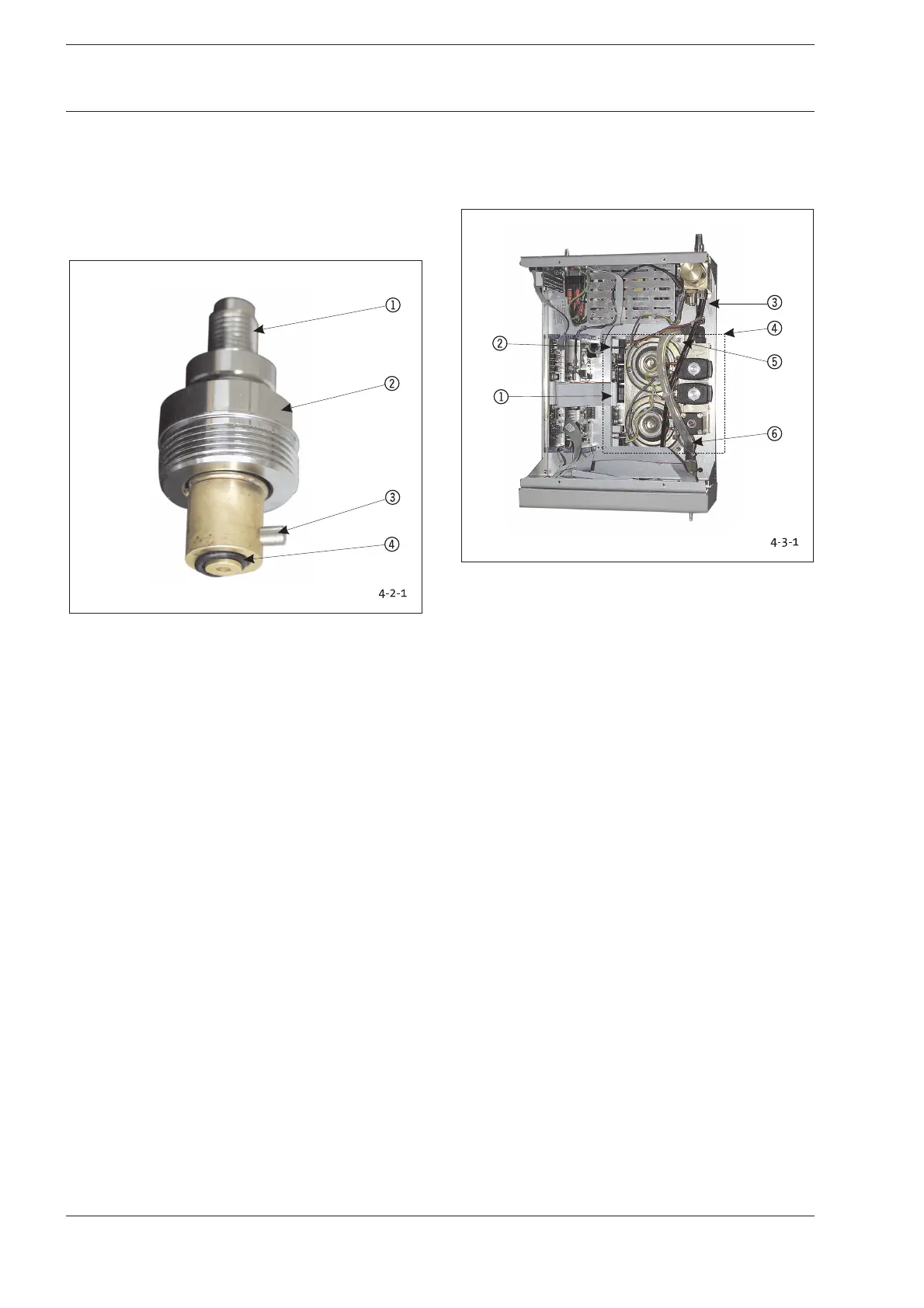

4-3 Low Pressure Unit LPU

Replace elements if malfunctioning and in case of flow

limitation.

Fig. 4-3-1: Position LPU

1 Flat Cable/Plug-in Connection

2 Electrical Plug-in Connection with High Pressure Unit

3 Tube Connection with HPU

4 Complete LPU

5 SW 7 Nut / Tooth Lock Washer (4x)

6 Connection Tube

1. Remove the connection tube from the LPU 36.

2. Unscrew the plug-in connections for the electronic plugs

12.

3. Unscrew four fastening nuts 5 at base case of

pneumatics unit; remove the tooth lock washers, and lift

out the entire LPU complete with block, valves, and board.

Reverse instructions to install elements.

Conduct the following tests after replacing modules or

components:

1. Calibration according to Chapters 3-2-1 to 3-2-6 and

Chapter 3-2-8.

4 Replacing Components 4 Replacing Components

Loading...

Loading...