Cyclo® HBB

Operation & Maintenance Manual 11

Cyclo® HBB

Installation onto Driven Shaft

Using Taper-Grip® Bushing

11

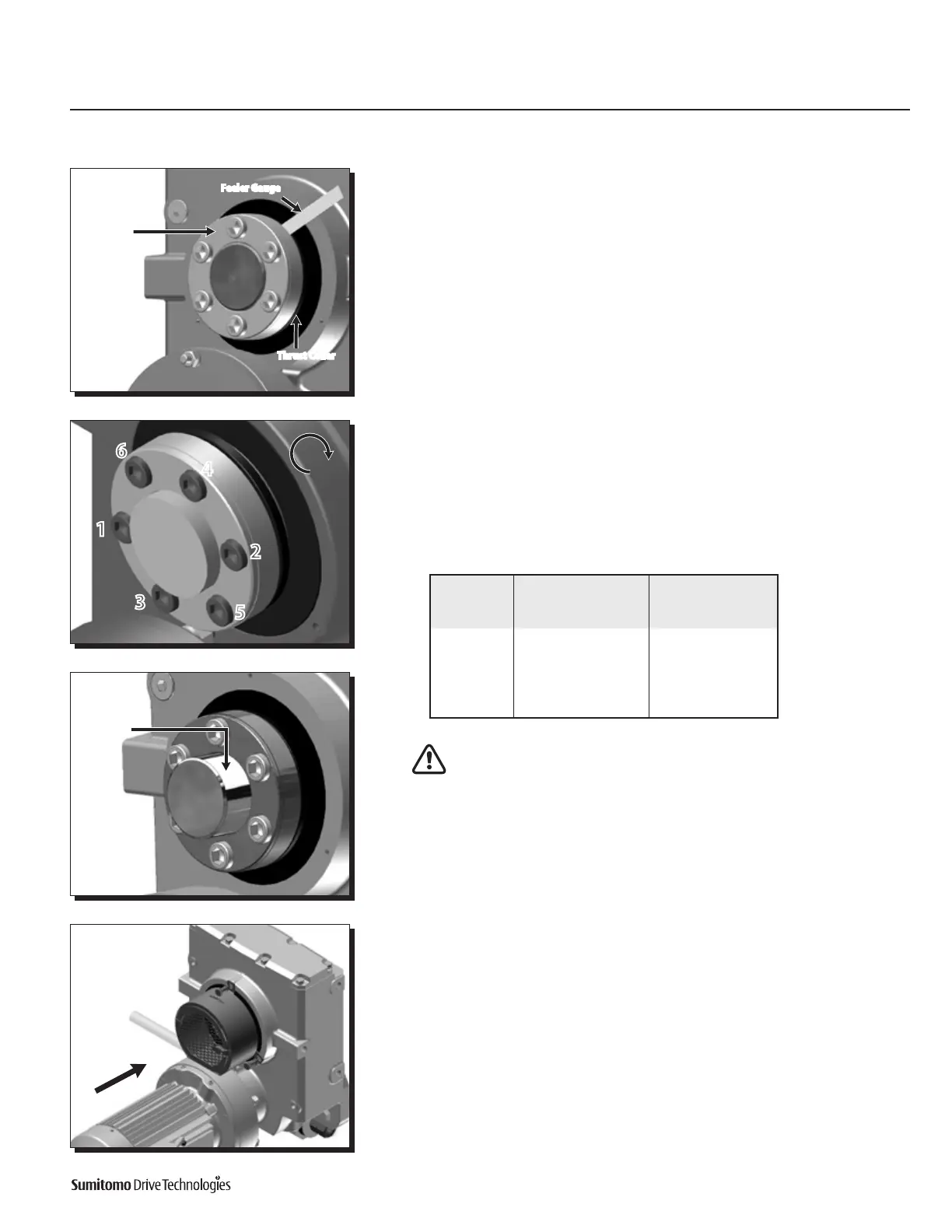

Screw bolts into Taper-Grip bushing.

• Lightlyoilthethreadsofeachboltbeforeinserting.

• Fingertighteneachbolttosecureinplace

• Besuretomaintain the 1 mm (approximate) gap between the thrust collar

and the bushing flange.

12

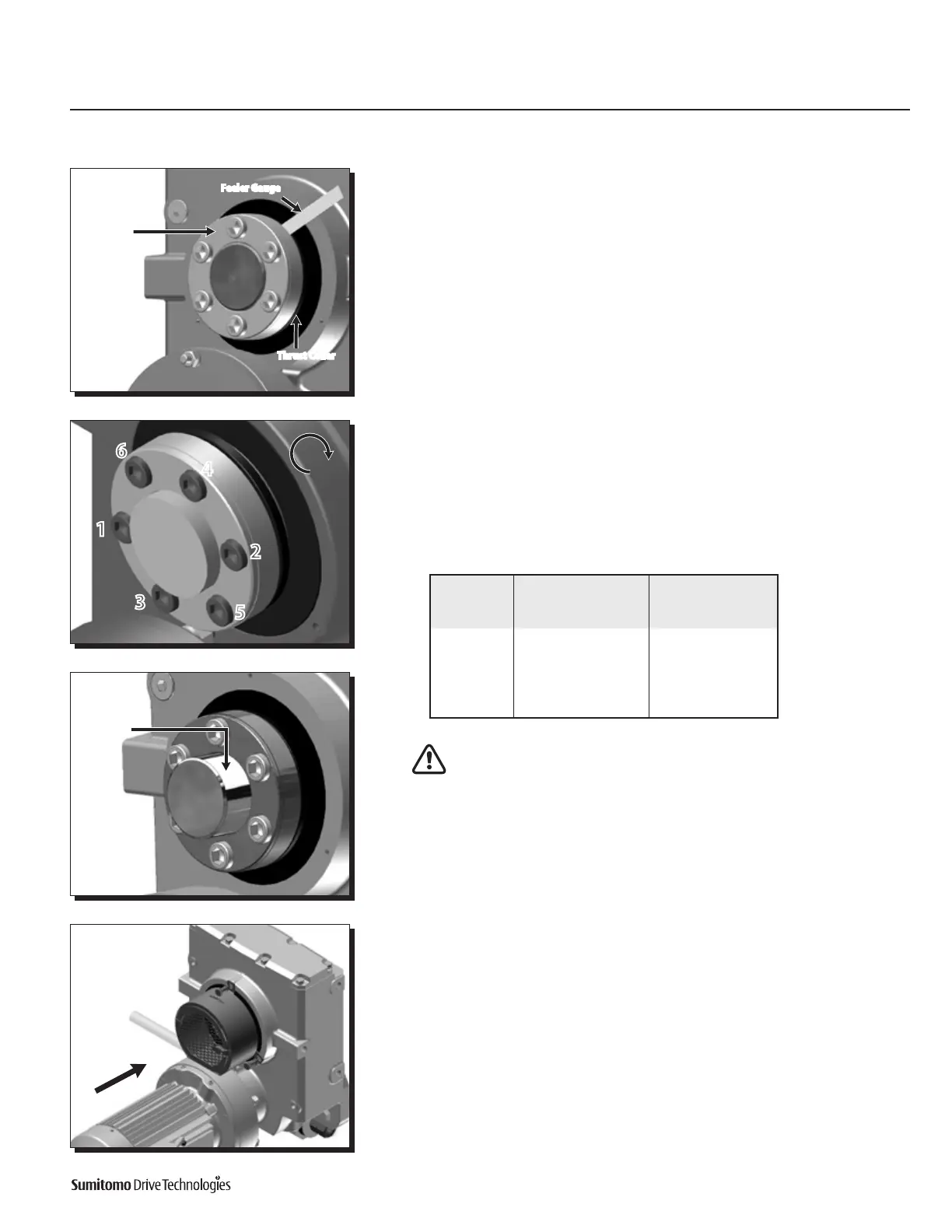

Tighten bushing bolts to the correct torque value.

• Followingastarpattern,useatorquewrenchtogradually tighten each socket

head cap screw in 20% increments.

• RefertoTable 1, Taper-Grip Bushing Bolt Tightening Torques, for the correct

operational screw torques.

After the reducer has been running for 20 to 30 hours, re-torque the screws

tothevaluesinTable2.Screwtorquesshouldbesubsequentlycheckedat

normal service intervals (i.e. every 6 months).

13

Apply grease to the exposed portion of the driven shaft.

• After installing and tightening the bushing bolts with a torque wrench, apply

grease or an anti-corrosion product to the exposed portion of the shaft.

14

For units that include a bushing safety cover, reinstall the guard over the

Taper-Grip® bushing.

Bushing

Flange

1-3mm

Feeler Gauge

Thrust Collar

1

6

4

2

5

3

Apply grease

to exposed

portion of

driven shaft.

Table 2. Taper-Grip® Bushing Bolt Tightening Torques

Cyclo® HBB

Model

Cap screws

(JISGrade12.9)

Cap screw

Torque

Qty. Size Nm Lb.Ft.

Z 6 M10x14 31 23

A 6 M12x16 51 37.5

B 6 M12x16 51 37.5

C 6 M16x20 128 95

D 6 M16x20 200 148

E 8 M16x20 200 148

Loading...

Loading...