69

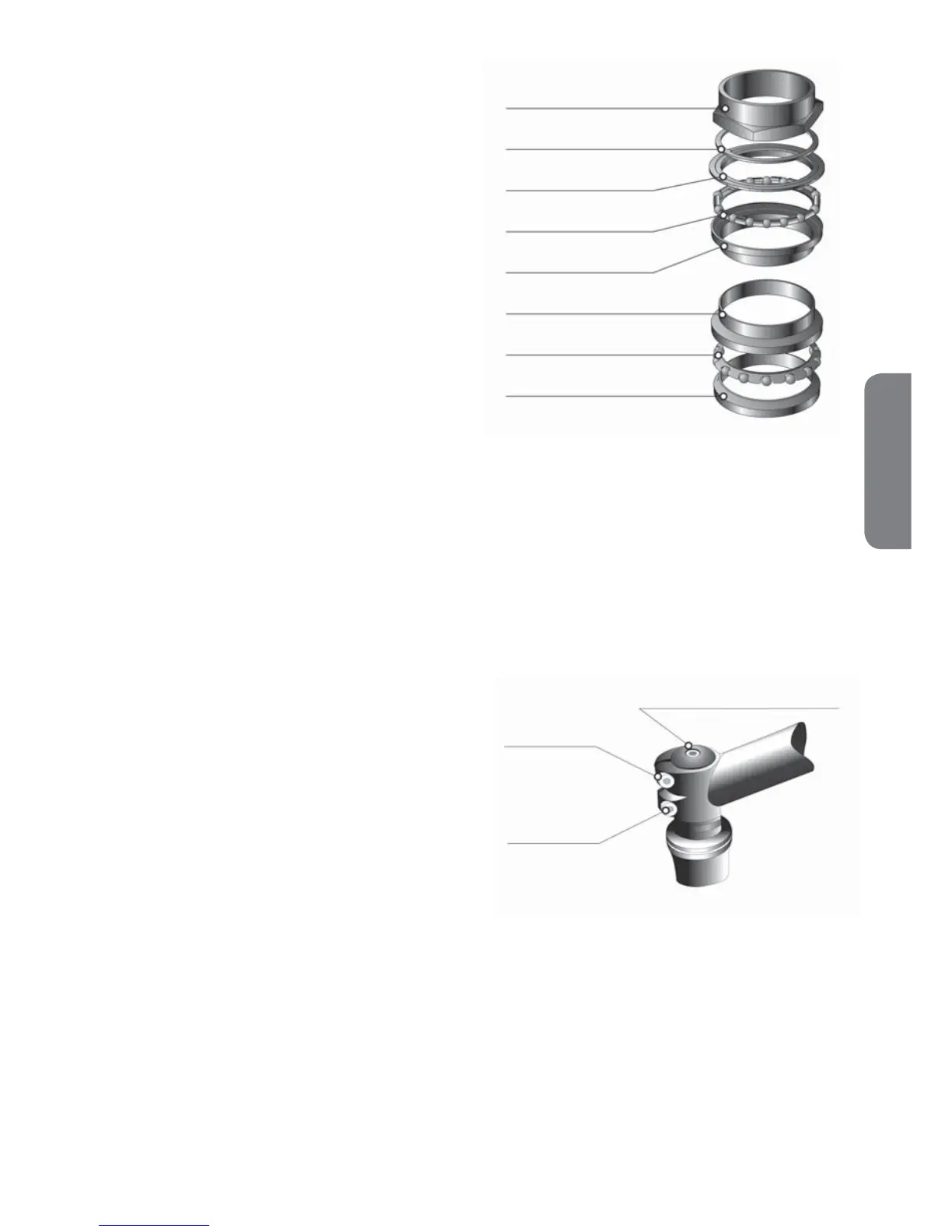

Locking nut

Spring washer

Adjustable pan

Ball ring

Stationary cone

Fixed pan

Ball ring

Cone with channel

ADJUSTMENT OF THE BEARINGS

Your mountain bike is provided with four sets of bearings that

require adjustment and lubrication.

1) Quill assembly

2) Bottom bracket assembly

3) Wheel hub bearings

4) Pedal bearings

Inspect the bearings frequently, in particular after riding over

rough terrain. The service interval depends on the number of

kilometres covered and the riding conditions. Even if the bearings

are sealed effectively, the sealings used on the bike are not fully

resistant to water. You should be able to lubricate and adjust the

bearings by yourself with some skills and the appropriate tools.

QUILL ASSEMBLY

• Remove the front wheel to inspect the adjustment. The fork should allow free rotation; however without backlash.

• If the bearings require adjustment, loosen the locking nut with two side spanners. Tighten or loosen the adjustable ring. Install

the locking nut and perform a check.

• Disassemble the handlebar for lubrication of the bearing. Remove the locking nut and the adjustable ring. Pull the fork out of

the frame and remove the two ball cages. Clean the lubricant off all the components and inspect the bearing paths for wear and

the presence of rust. Lubricate all the components again, in particular cover the ring sealing sufficiently. Install one ball cage

on the fork. Insert the fork back into the frame and make sure that the ring has fitted back on the bottom of the stationary ring.

Install the other ball cage on the stationary cone. Screw down the adjustable ring until a play exists. Screw in the locking nut.

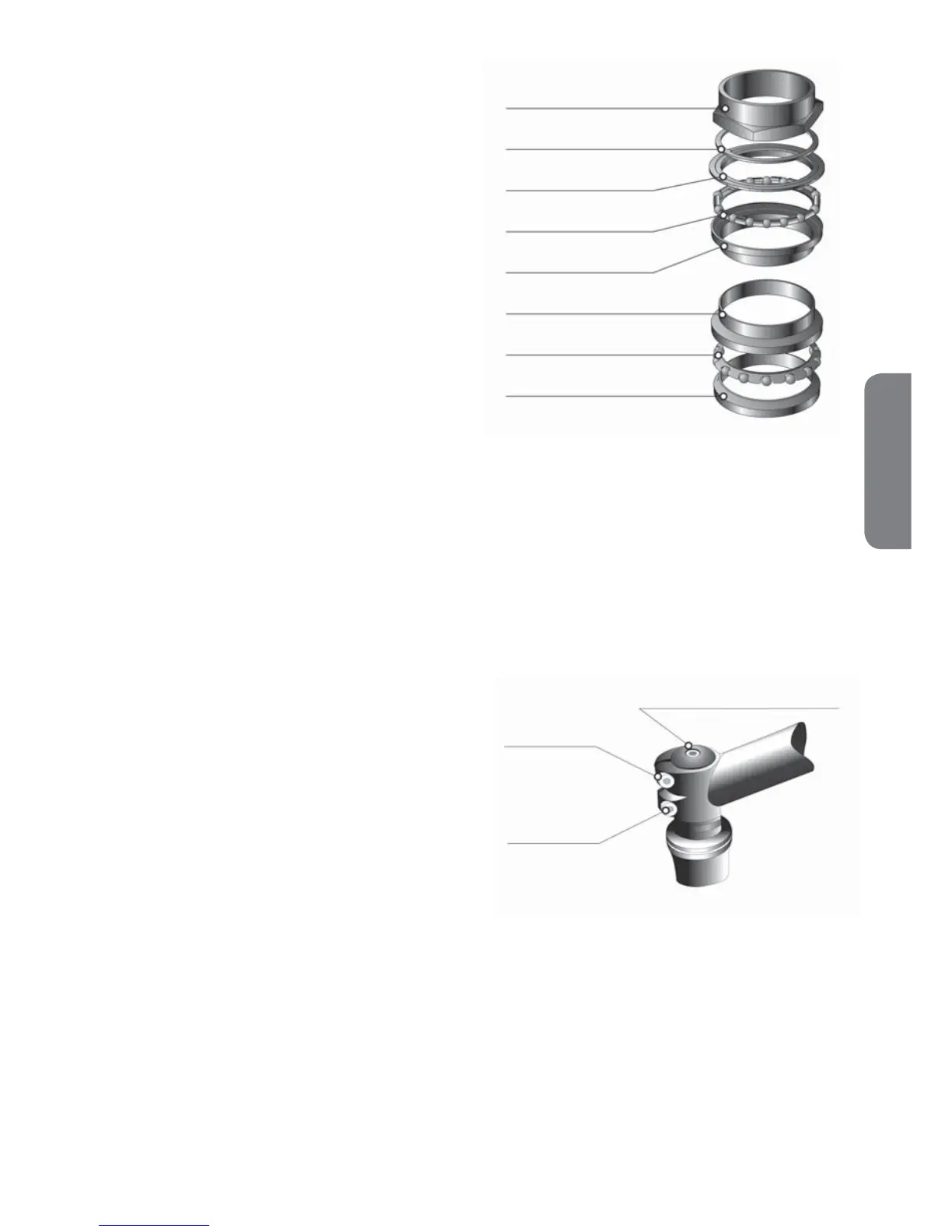

AHEAD QUILL ASSEMBLY TIGHTENING

• Loosen the bolts in the stem and the quill assembly bolt.

• The handlebar is perpendicular with respect to the front wheel.

• Tighten the quill assembly bolt in the stem and all stem bolts

firmly.

• Check to ensure that the tightening is correct by holding

the front wheel between your legs and trying to turn the

handlebar.

HUBS

• Remove the quick-release mechanism.

• Unscrew the axle locking nut, spring washer and the cone from one side of the axle. Pull the axle freely out of the hub core and

remove the ball bearings.

• Check to ensure that the ball paths are not damaged or corroded (replace them if necessary).

• Lubricate the hub box and insert the bearings.

• Put back the axle. Screw the cone in until it touches the ball bearings. Put back the spring washer and locking nut.

Try to turn the axle. It should rotate without backlash or dragging. Readjust if necessary and tighten the locking nut.

Re-install the quick-release mechanism.

1. Loosen

3. Tighten (until play is limited)

2. Loosen

4. Tighten

5. Tighten

ENGLISH

Loading...

Loading...