机床产品/Machine Tool Products

–

22/220 Series Controller Application Manual

Pitch Error Compensation–36

•

•

•

•

1.

8.6 Operation Steps

Step 1: Disable all mechanical compensations (Pitch: Pr130x; Backlash: Pr122x, Pr124x, Pr126x, Pr128x;

Quad-peak: Pr136x, Pr144x), and do Homing action.

Step 2: Load the attached example program, and then use the instruments to measure the pitch error of

every compensation point.

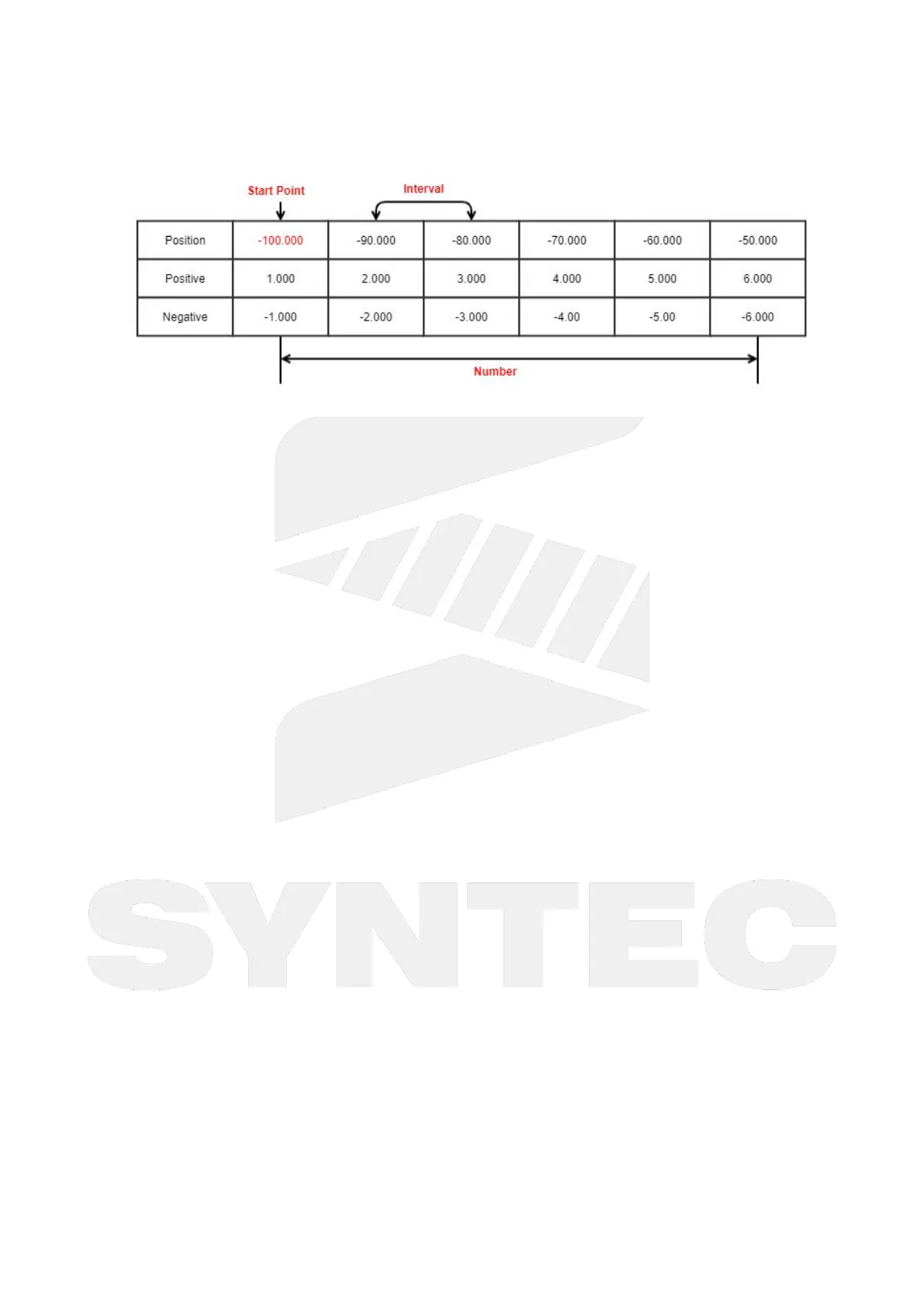

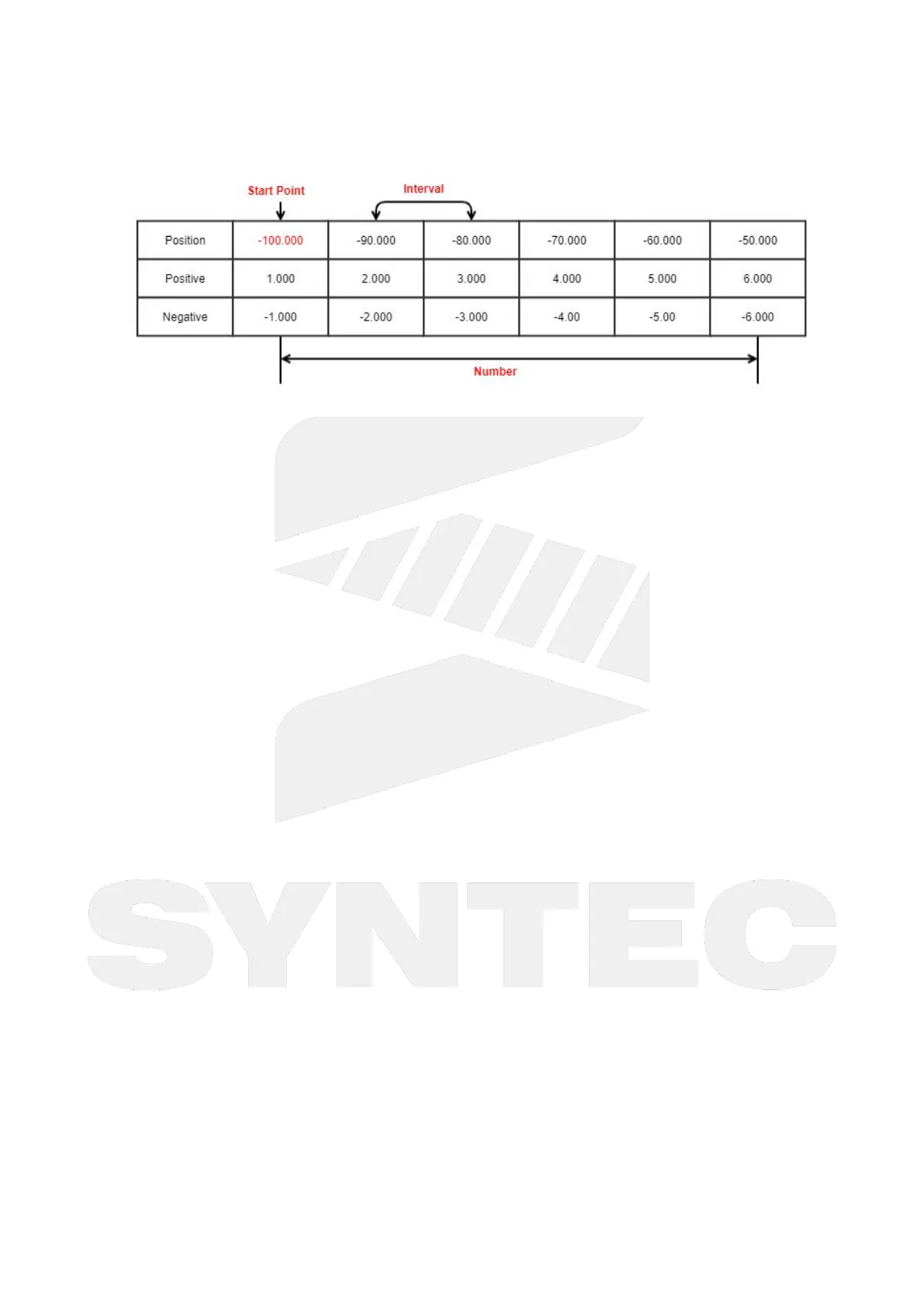

Step 3: According to pitch compensation type (uni-directional/bi-directional), and stroke direction of axis

(positive/negative), fill in the table with corresponding type.

Step 4: Measure pitch error again with compensation enabled to verify the result.Compensation table setting

8.7 Q & A

Q1: Machine isstill inaccurate after pitch error compensation enabled, what is the possible cause?

A1: The effectiveness of mechanical compensation highly depends on the repeatability of the machine. Please

check machine assembly quality first if compensation result is not ideal.

8.8 Remark

Example program (X-axis as an example)

% @MACRO

#2:=20;// Pitch Compensation Length(mm), No132x

#3:=50;// Compensation Point Number

G54G00G90X-1.;

G4X0.1;

X0.;

G91;

#10:=1;// Leave away home

FOR #10 = 1 TO #3 BY 1 DO

X(#2*1.);G4X2.;

END_FOR;

#10:=1;// Back to home

FOR #10 = 1 TO #3 BY 1 DO

X(#2*-1.);G4X2.;

END_FOR;

M30;

Loading...

Loading...