机床产品/Machine Tool Products

–

22/220 Series Controller Application Manual

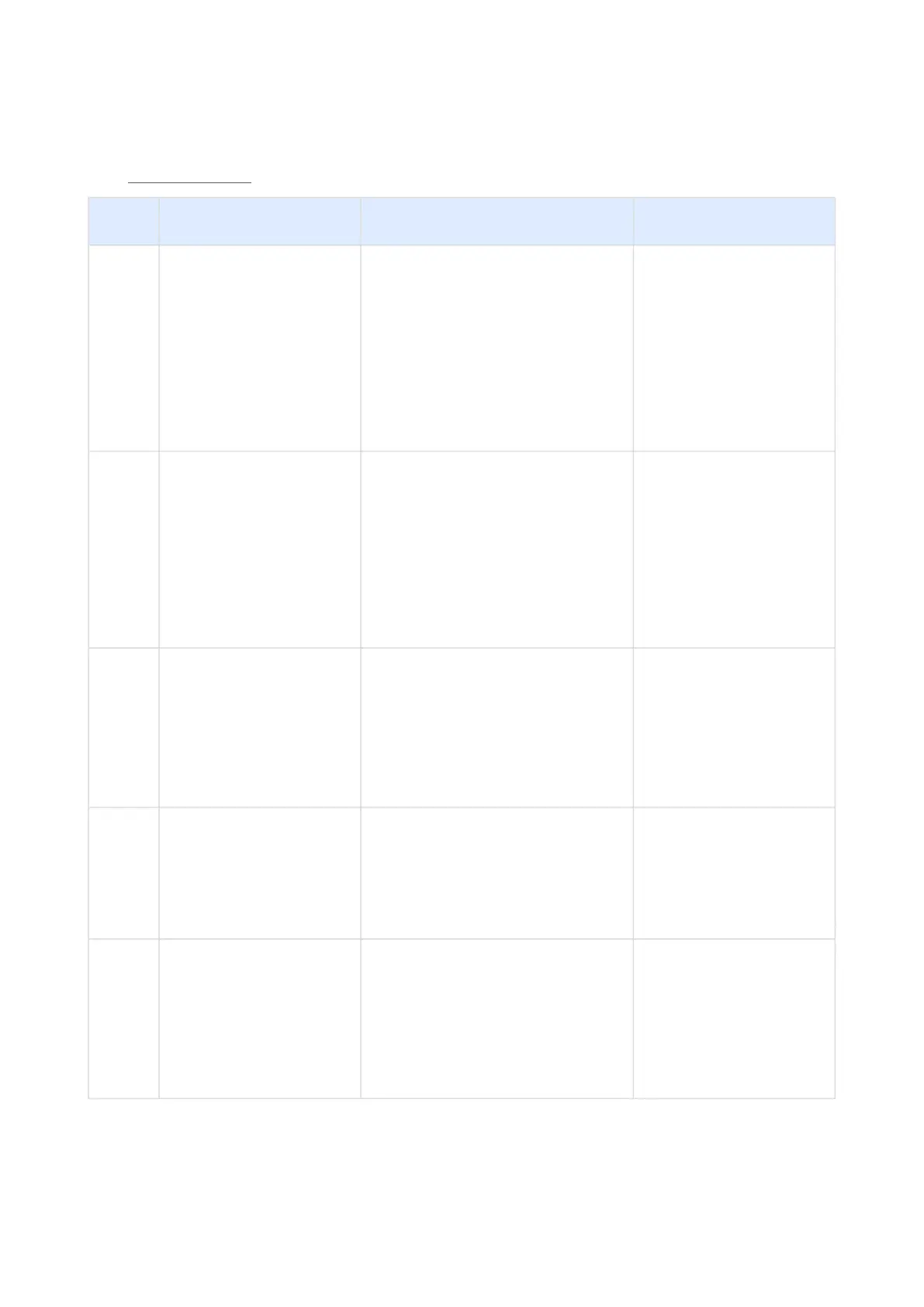

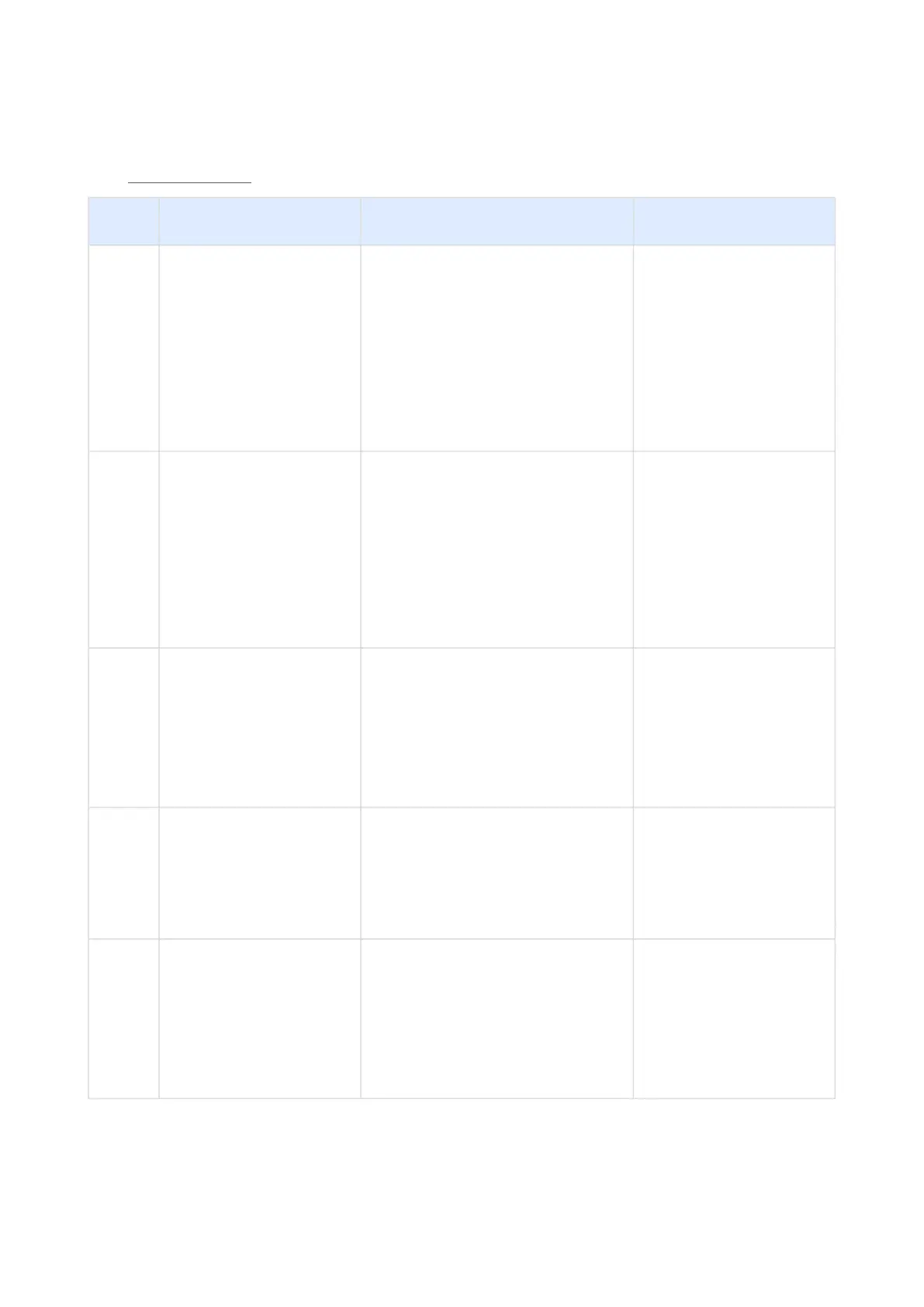

14 Check List

No. Item Content Result

1 Absolute origin Move each axis to specific location and

set up the absolute origin.

After reboot, check the machine

coordinate are all correct.

Also check the flag S16~S18 are

activated normally.

PS. S16~S18 are the flags of origin

setting completed.

□ Yes/□ No

2 Software limit After origin is ready, set up the

software limit on theappropriate

position.

5mm from mechanism limit or

hardware limit switch is

recommended.

PS. Software limit could be set with

Pr2401~Pr2441.

□ Yes/□ No

3 Lubrication Check the specification of lubrication

is designed properly.

Check the lubrication is working

normally.

Check if the alarm occur when the oil is

not enough.

Interval = _____(sec)

Lubricating = _____(sec)

Alarm:□ Yes/□ No

4 Spindle loading Check the motor current is between

1/3~1/2 of rated current without load.

Based on three conditions:spindle

orientation、rated speed、max.

speed.

Orientation = _____(%)

Rated speed = _____(%)

Max. speed = _____(%)

5 Auto tuning & Kp setting Use auto tuning function to do servo

tuning.

After tuning, the Kp(position loop

gain) of XYZ should be the same.

PS. The minimum value of Kp between

XYZ should be used.

Pr181 = _____(1/s)

Pr182 = _____(1/s)

Pr183 = _____(1/s)

Loading...

Loading...