Maintenance Manual November 2021

Programmed Maintenance Procedures

80 Scissor Lifts Part No. 1305686GT

P2-3

Check the Free-wheel

Configuration - GS-84, GS-90

Genie requires that this procedure be performed

every 2000 hours.

Proper use of the free-wheel configuration is

essential to safe machine operation. The free-

wheel configuration is used primarily for towing. A

machine configured to free-wheel without operator

knowledge may cause death or serious injury and

property damage.

Collision hazard. Select a work

site that is firm and level.

Component damage hazard. If

the machine must be towed, do

not exceed

2 mph / 3.2 km/h.

Non-Steer wheels:

1 Chock the steer wheels to prevent the

machine from rolling.

2 Center a lifting jack of ample capacity

(20,000 lbs / 10,000 kg) under the drive

chassis between the non-steer tires.

3 Lift the wheels off the ground and then place

jack stands under the drive chassis for

support.

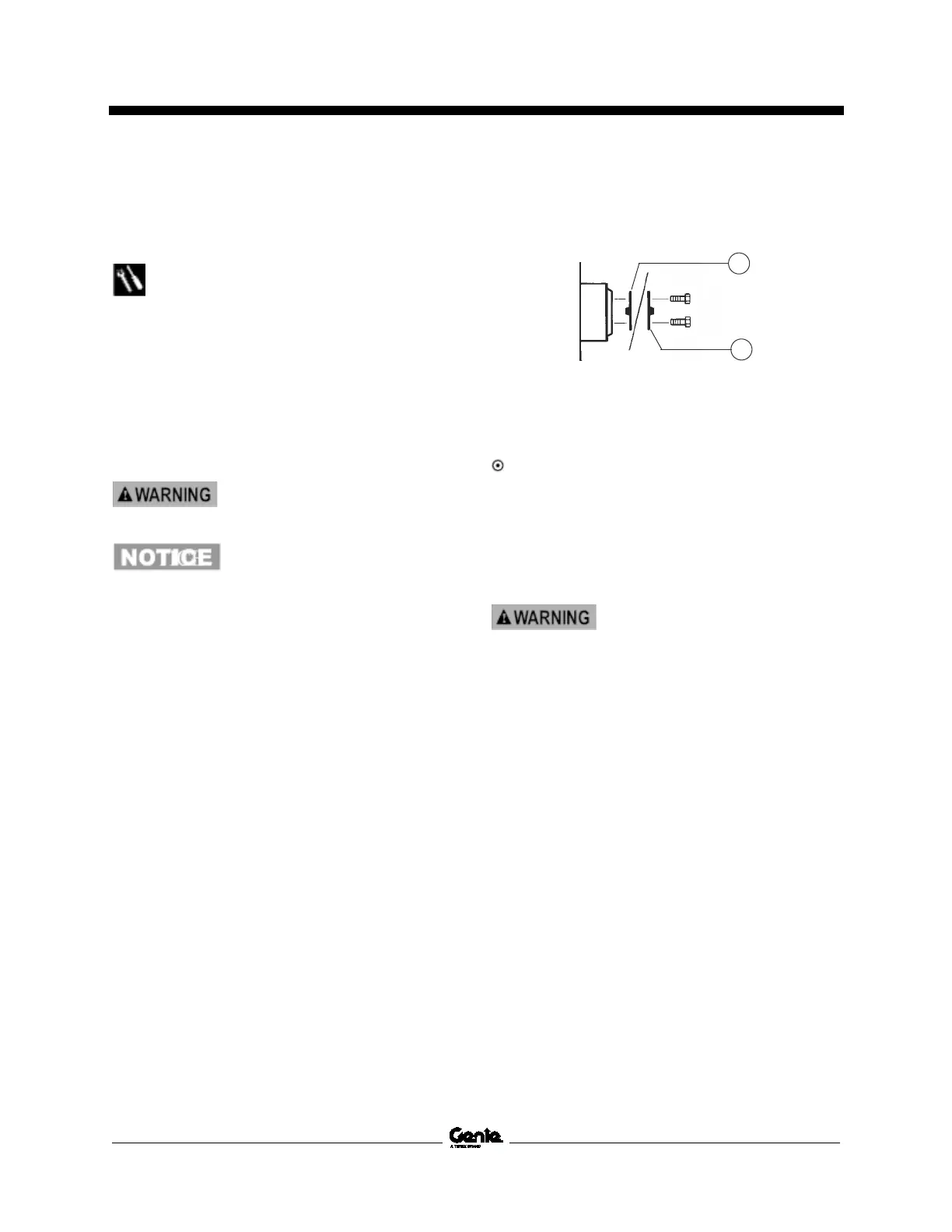

4 Disengage the drive hubs by turning over the

drive hub disconnect caps on each non-steer

wheel hub.

1 brake disengaged position

2 brake engaged position

5 Manually rotate each non-steer wheel.

Result: Each non-steer wheel should rotate

with minimum effort.

6 Re-engage the drive hubs by turning over the

hub disconnect caps. Rotate each wheel to

check for engagement. Raise the machine,

remove the jack stands and lower the

machine.

Collision hazard. Failure to re

-

engage the drive hubs could

result in death or ser

ious injury

Steer wheels:

7 Chock the non-steer wheels to prevent the

machine from rolling.

8 Center a lifting jack of ample capacity

(20,000 lbs / 10,000 kg) under the drive

chassis between the steer tires.

Loading...

Loading...