Maintenance Manual November 2021

Programmed Maintenance Procedures

82 Scissor Lifts Part No. 1305686GT

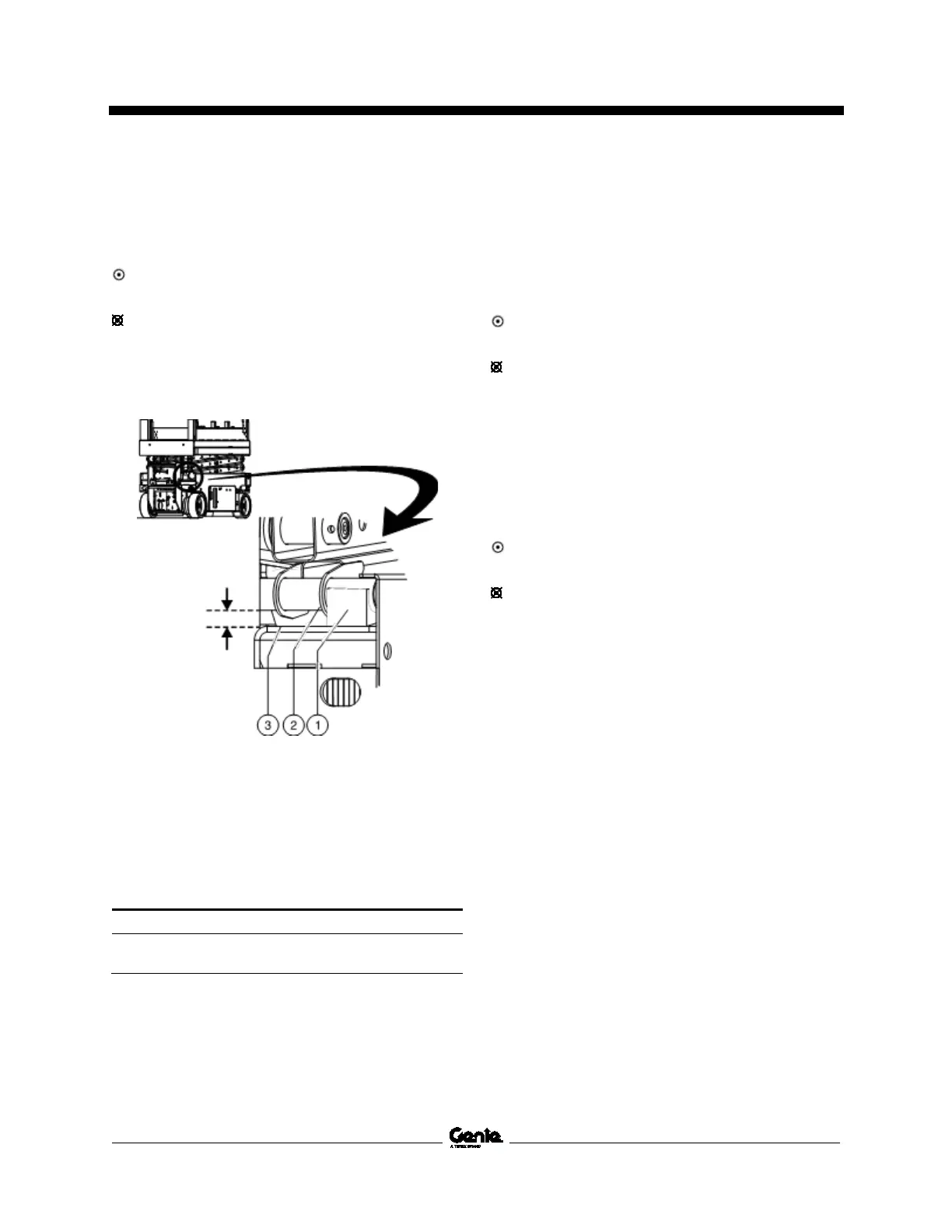

2 Measure the distance between the number

one inner arm cross tube and the chassis

deck at the battery pack side of the non-steer

end of the machine. Refer to illustration 1.

Result: The measurement is 0.90 inch /

22.9 mm or more. Proceed to step 3.

Result: The measurement is less than

0.90 inch / 22.9 mm. Replace both wear pads.

Refer to Repair Procedure in the appropriate

Service and Repair Manual for your machine,

How to Replace the Scissor Arm Wear Pads.

Illustration 1

1 wear pad

2 inner arm cross tube

3 chassis deck

3 Apply a thin layer of dry film lubricant to the

area of the chassis where the scissor arm

wear pads make contact.

Cross tube to chassis specification

0.90 i

22.9 m

GS-2032, GS-2632, GS-3232, GS-2046, GS-2646,

GS-3246:

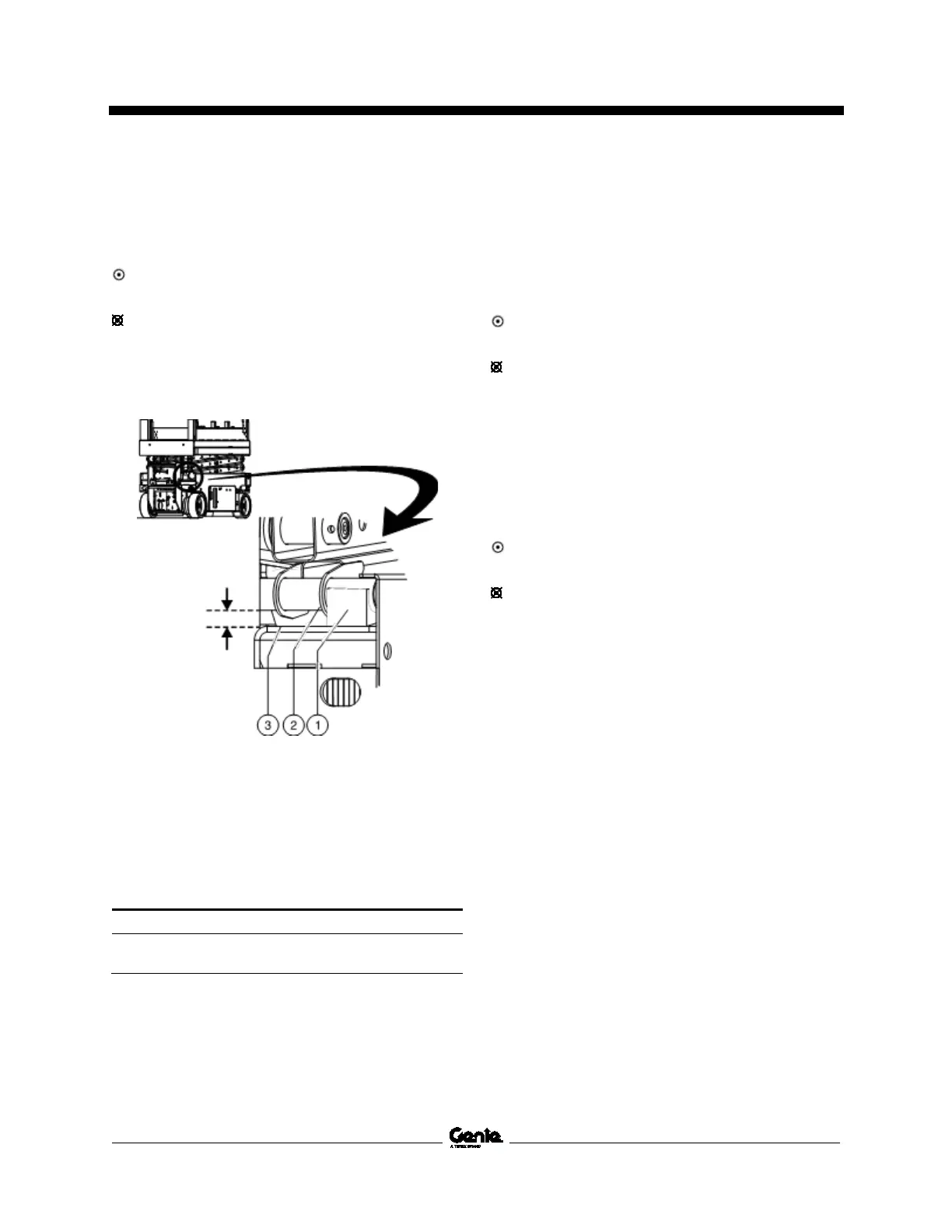

1 Measure the distance between the number

one outer arm cross tube and the fork lift tube

at the ground controls side of the non-steer

end of the machine. Refer to Illustration 2.

Result: The measurement is 0.88 inch /

22.4 mm or more. Proceed to step 2.

Result: The measurement is less than

0.88 inch / 22.4 mm. Replace both wear pads.

Refer to Repair Procedure in the appropriate

Service and Repair Manual for your machine,

How to Replace the Scissor Arm Wear Pads.

2 Measure the distance between the number

one outer arm cross tube and the fork lift tube

at the battery pack side of the non-steer end

of the machine. Refer to Illustration 2.

Result: The measurement is 0.88 inch /

22.4 mm or more. Proceed to step 3.

Result: The measurement is less than

0.88 inch / 22.4 mm. Replace both wear pads.

Refer to Repair Procedure in the appropriate

Service and Repair Manual for your machine,

How to Replace the Scissor Arm Wear Pads.

Loading...

Loading...