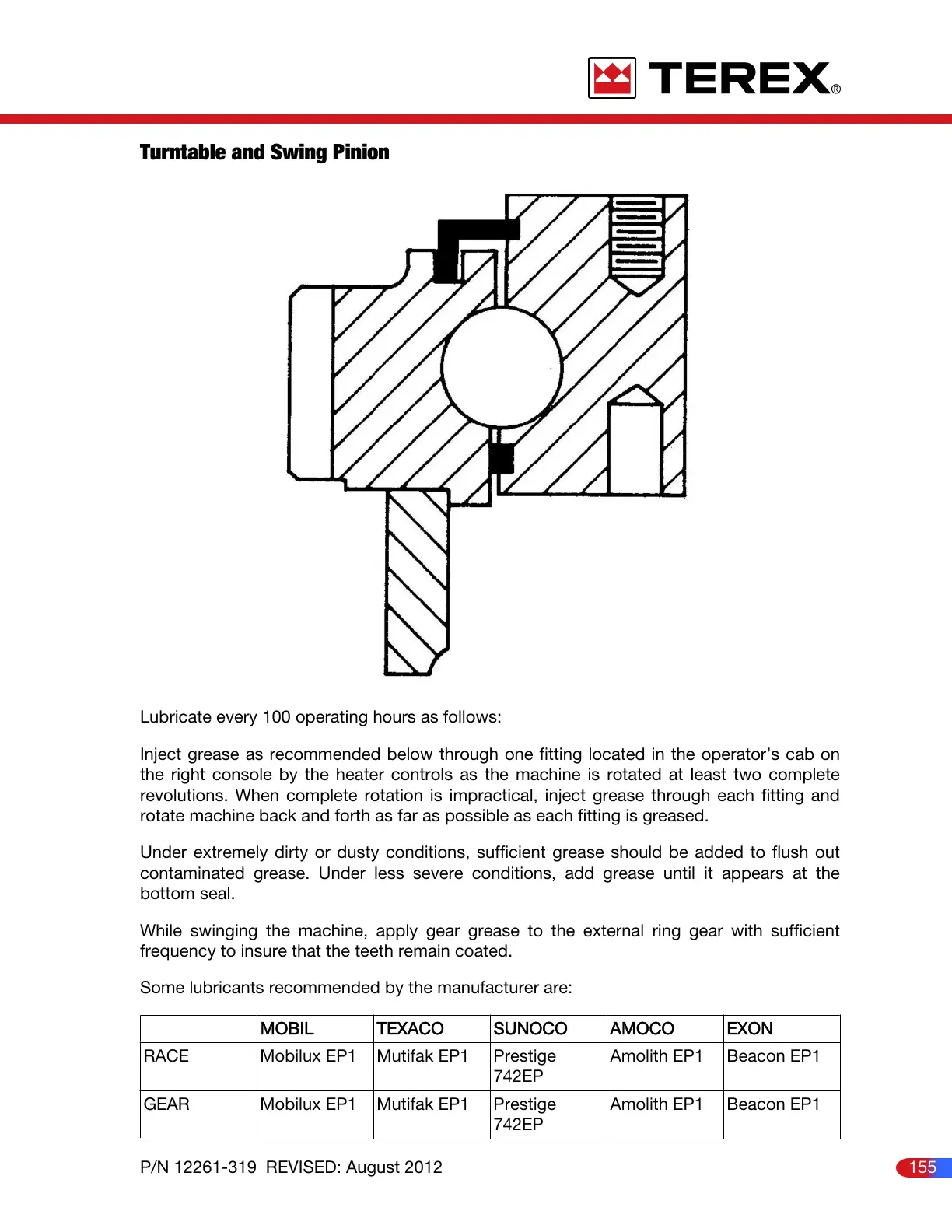

Turntable and Swing Pinion

Lubricate every 100 operating hours as follows:

Inject grease as recommended below through one fitting located in the operator’s cab on

the right console by the heater controls as the machine is rotated at least two complete

revolutions. When complete rotation is impractical, inject grease through each fitting and

rotate machine back and forth as far as possible as each fitting is greased.

Under extremely dirty or dusty conditions, sufficient grease should be added to flush out

contaminated grease. Under less severe conditions, add grease until it appears at the

bottom seal.

While swinging the machine, apply gear grease to the external ring gear with sufficient

frequency to insure that the teeth remain coated.

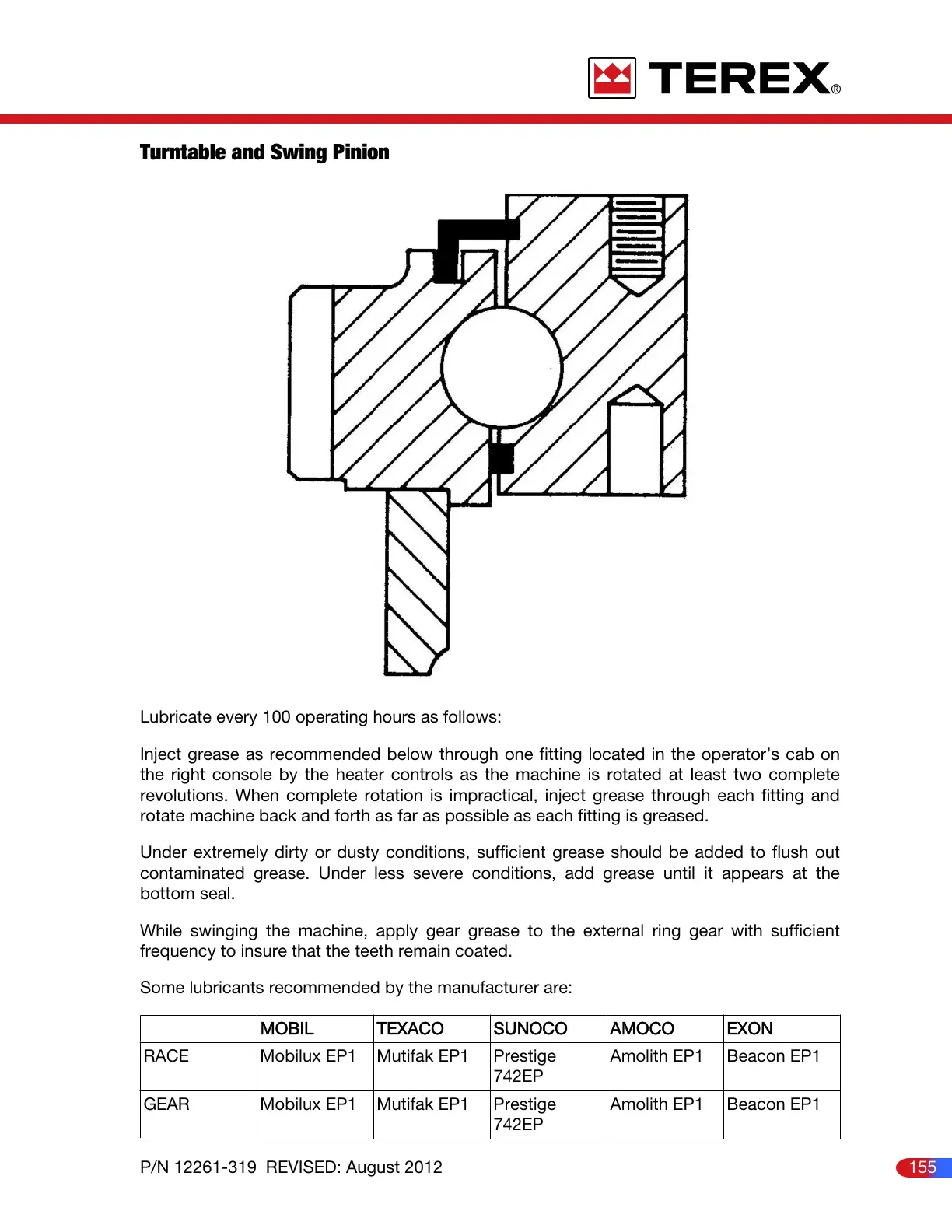

Some lubricants recommended by the manufacturer are:

MOBIL TEXACO SUNOCO AMOCO EXON

RACE Mobilux EP1 Mutifak EP1 Prestige

742EP

Amolith EP1 Beacon EP1

GEAR Mobilux EP1 Mutifak EP1 Prestige

742EP

Amolith EP1 Beacon EP1

155P/N 12261-319 REVISED: August 2012

Courtesy of Crane.Market

Loading...

Loading...