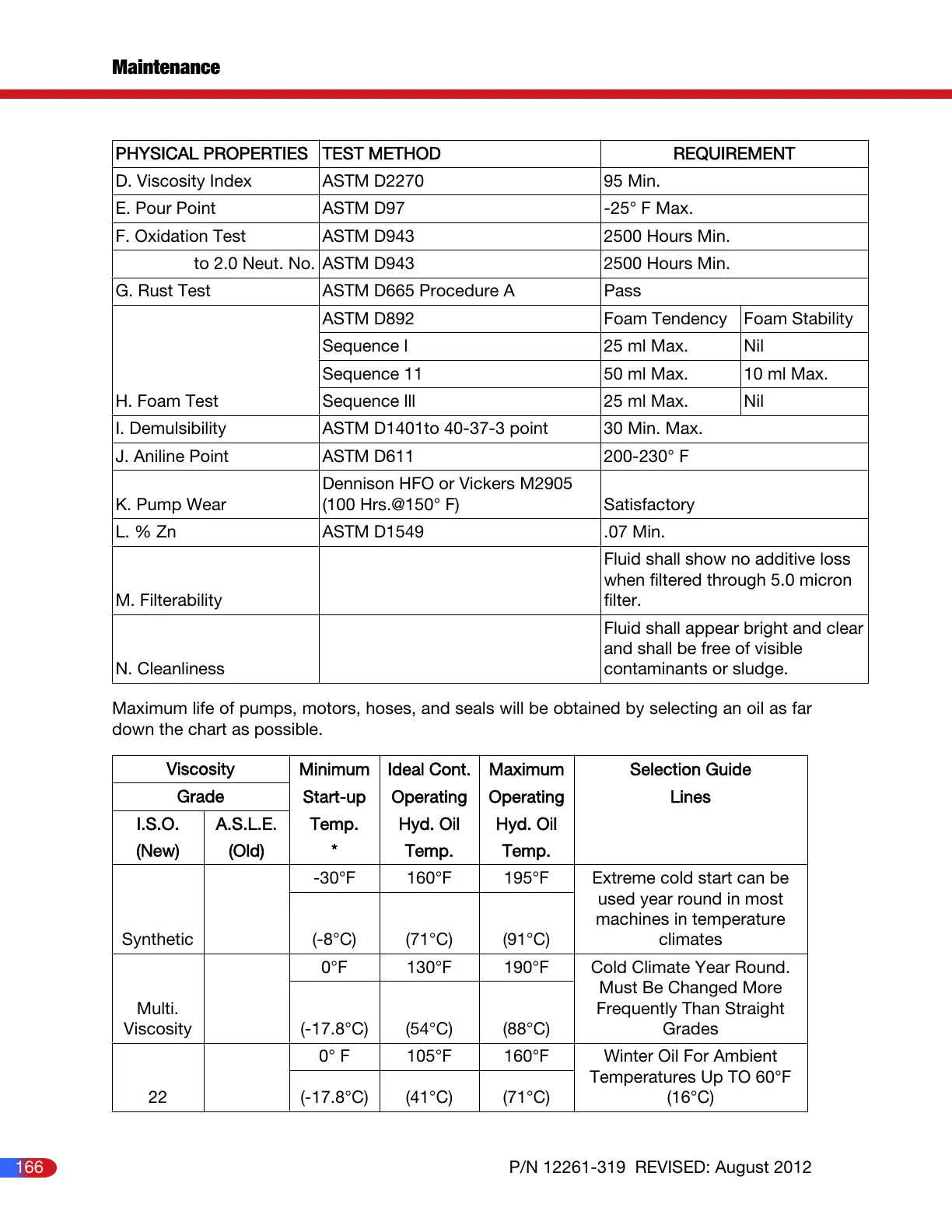

PHYSICAL PROPERTIES TEST METHOD REQUIREMENT

D. Viscosity Index ASTM D2270 95 Min.

E. Pour Point ASTM D97 -25° F Max.

F. Oxidation Test ASTM D943 2500 Hours Min.

to 2.0 Neut. No. ASTM D943 2500 Hours Min.

G. Rust Test ASTM D665 Procedure A Pass

H. Foam Test

ASTM D892 Foam Tendency Foam Stability

Sequence l 25 ml Max. Nil

Sequence 11 50 ml Max. 10 ml Max.

Sequence lll 25 ml Max. Nil

I. Demulsibility ASTM D1401to 40-37-3 point 30 Min. Max.

J. Aniline Point ASTM D611 200-230° F

K. Pump Wear

Dennison HFO or Vickers M2905

(100 Hrs.@150° F) Satisfactory

L. % Zn ASTM D1549 .07 Min.

M. Filterability

Fluid shall show no additive loss

when filtered through 5.0 micron

filter.

N. Cleanliness

Fluid shall appear bright and clear

and shall be free of visible

contaminants or sludge.

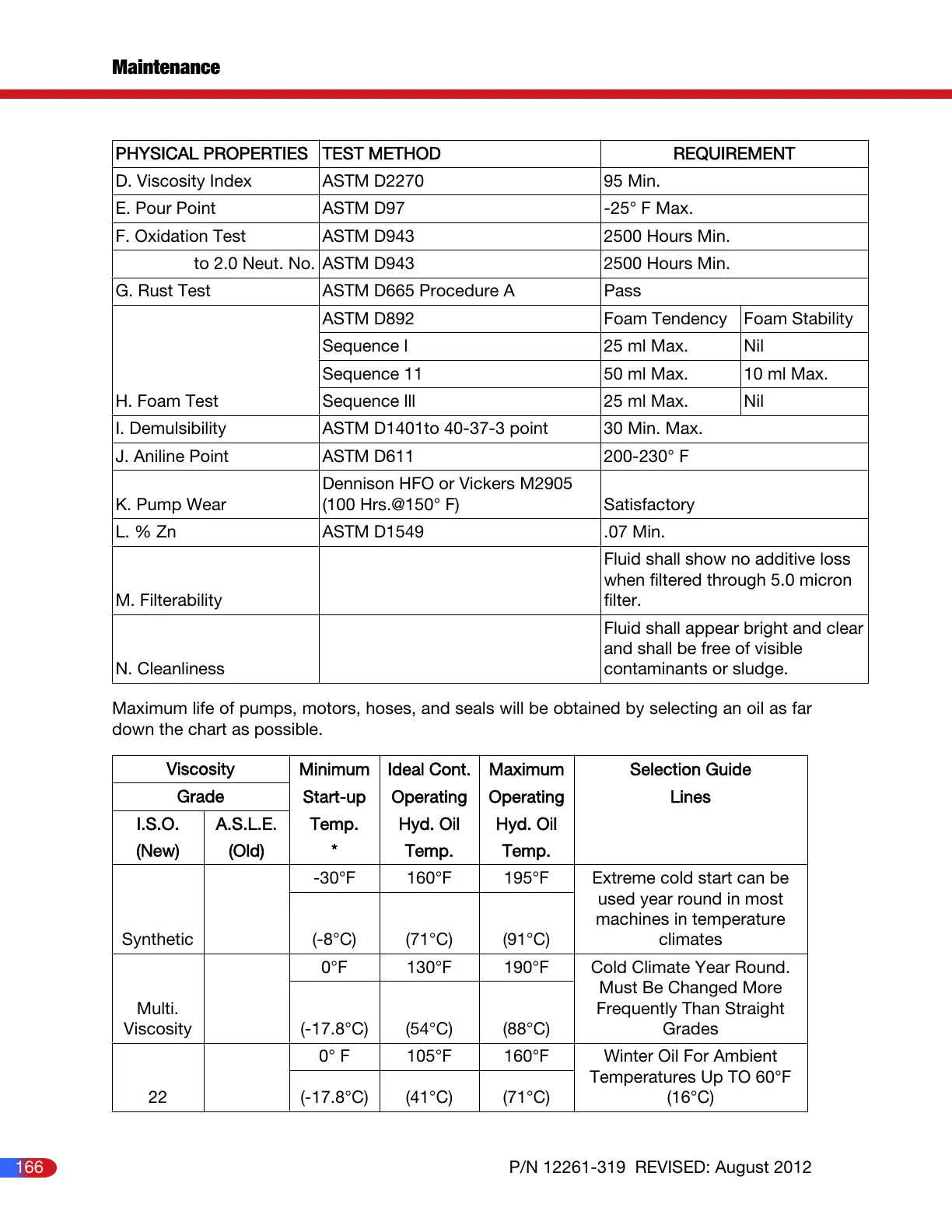

Maximum life of pumps, motors, hoses, and seals will be obtained by selecting an oil as far

down the chart as possible.

Viscosity

Minimum Ideal Cont. Maximum Selection Guide

Grade

Start-up Operating Operating Lines

I.S.O. A.S.L.E. Temp. Hyd. Oil Hyd. Oil

(New) (Old) * Temp. Temp.

Synthetic

-30°F 160°F 195°F Extreme cold start can be

used year round in most

machines in temperature

climates(-8°C) (71°C) (91°C)

Multi.

Viscosity

0°F 130°F 190°F Cold Climate Year Round.

Must Be Changed More

Frequently Than Straight

Grades(-17.8°C) (54°C) (88°C)

22

0° F 105°F 160°F Winter Oil For Ambient

Temperatures Up TO 60°F

(16°C)(-17.8°C) (41°C) (71°C)

Maintenance

166 P/N 12261-319 REVISED: August 2012

Courtesy of Crane.Market

Loading...

Loading...