34

.....Site selection & preparation

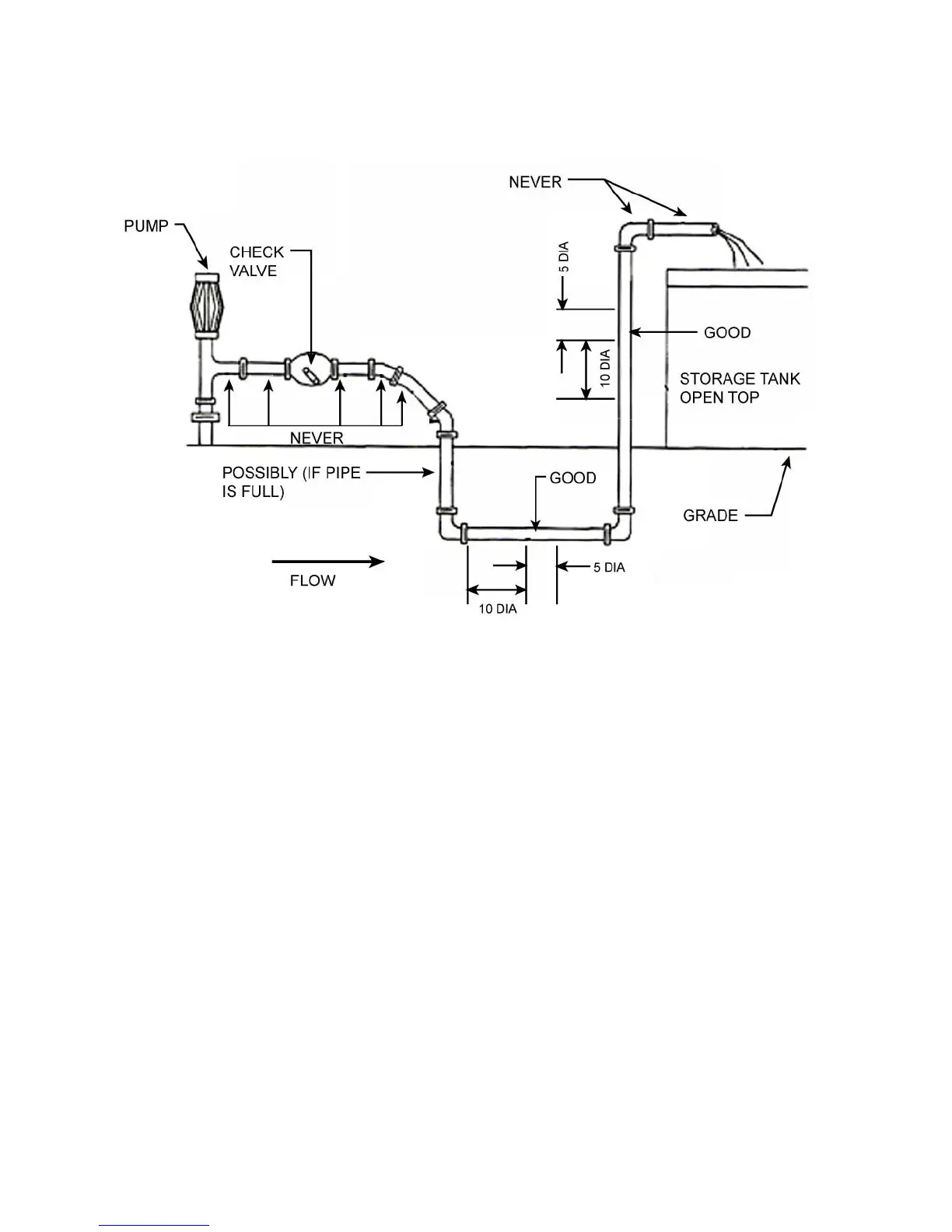

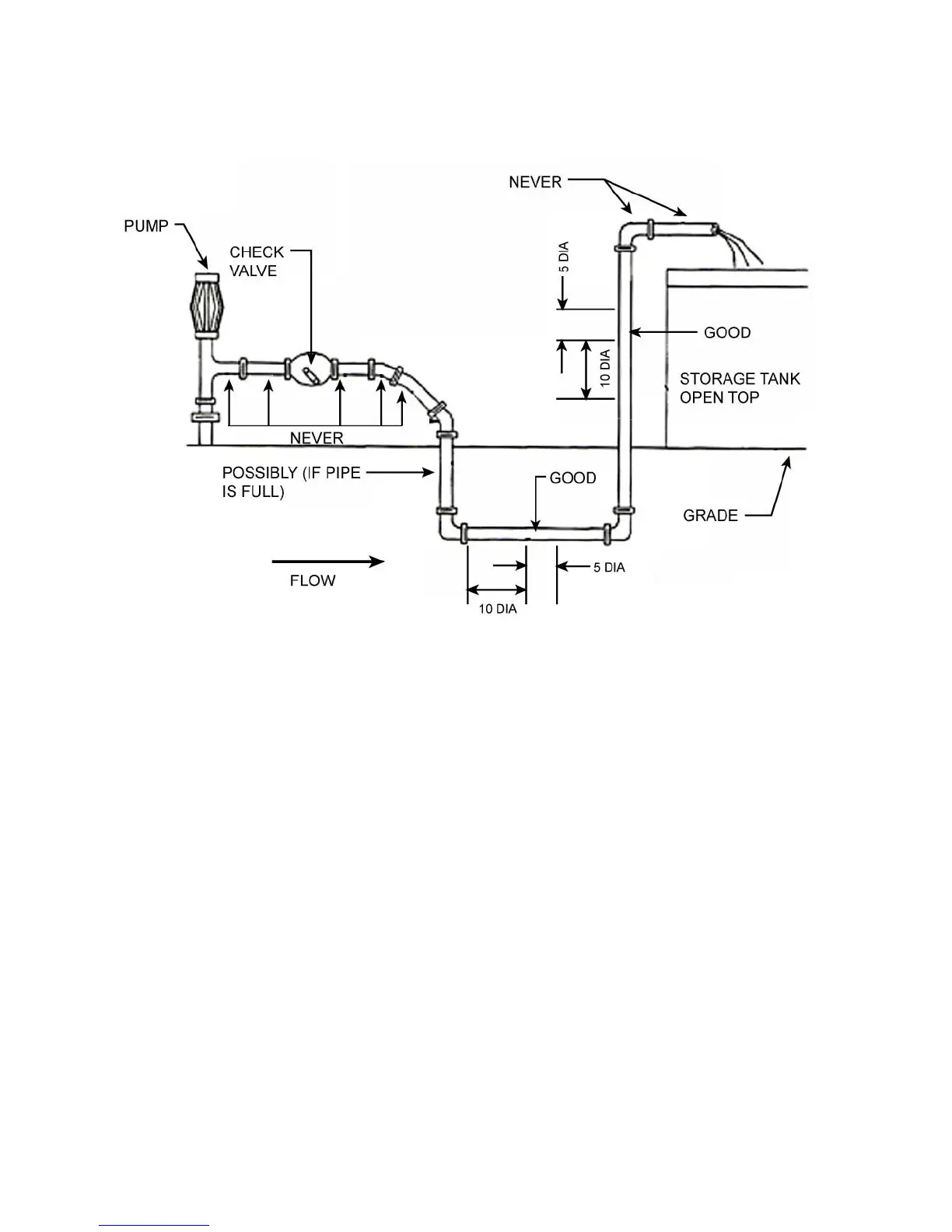

FIGURE 4.2-B

Use the following guidelines when selecting the transducer site:

a. Choose a section of pipe which is always full of liquid, such as a vertical pipe with up flow or a full

horizontal pipe.

b. The site should have a straight run equivalent to at least 10 pipe diameters upstream and 5 pipe

diameters downstream from any elbows, tees, throttling valves, orifices, reduced sections, or other

flow disturbances.

c. Up to 30 diameters of straight run may be required upstream from the flowmeter after a pump, control

valve, or double piping bend for greater accuracy. A distance of 5 diameters downstream is usually

sufficient under all circumstances.

d. Always mount the transducers on the sides of the pipe in the 3 o’clock or 9 o’clock positions on

horizontal pipes. Positioning the transducers in this manner prevents signal loss which can be caused

by sediment along the bottom of the pipe or gas bubbles and air pockets along the top of the pipe.

e. Ensure that the pipe skin temperature is within the transducer temperature rating. The transducers are

rated for -40º to +212º F (-40º to +100º C). Temperature ratings up to 392º F (200º C) are available

with optional high temperature transducers.

Loading...

Loading...