3-7

DRIVE MOTOR SPROCKET 3.4

Replacement

The torque motor drive sprocket can be removed from the

loader without removing the drive motor from the final

drive housing.

1 Place the loader on a level surface, engage the park-

ing brake and shut off the engine.

2 Raise the loader securely from the ground and

remove the wheels on the side to be worked on.

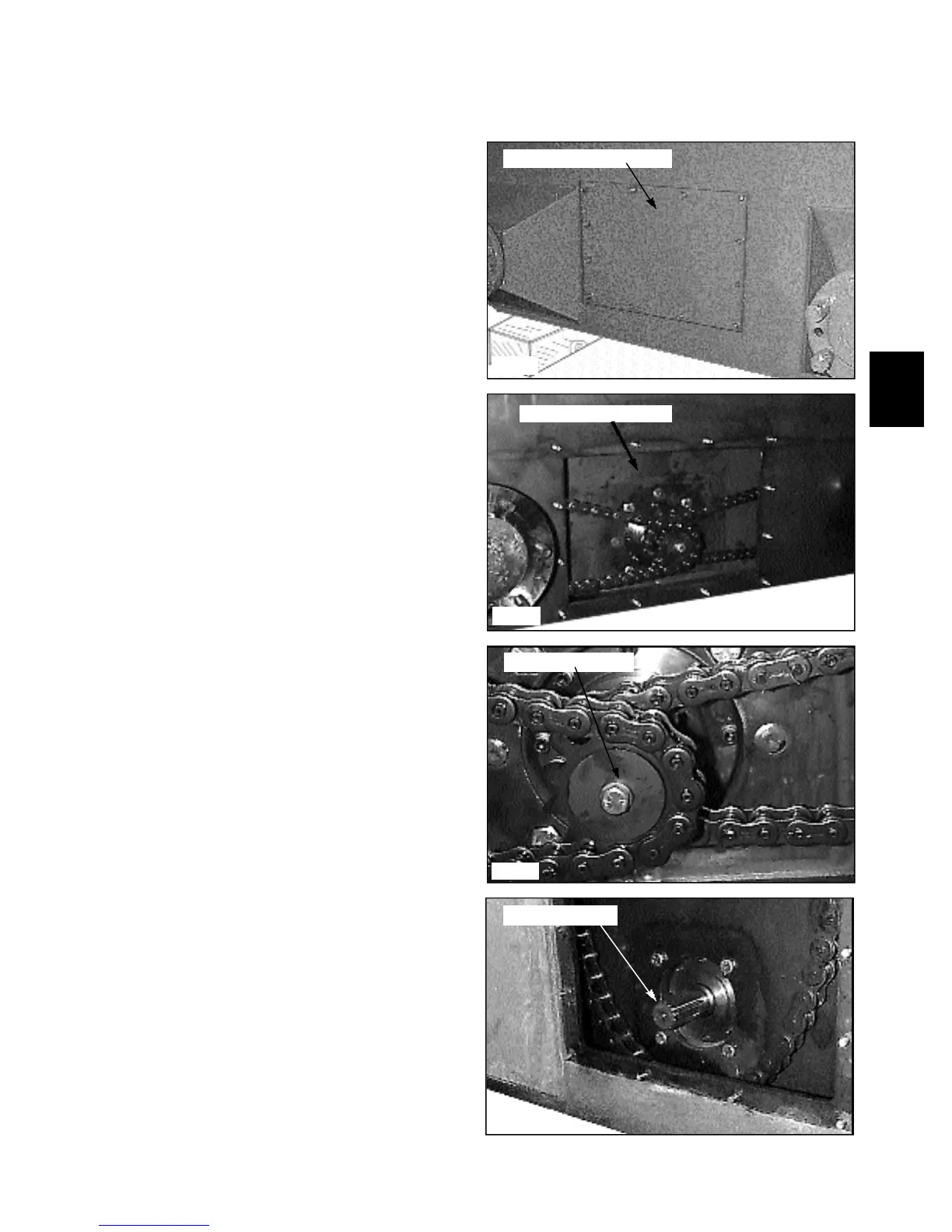

3 Remove the inspection cover located between the

axle assemblies. (fig. C2424)

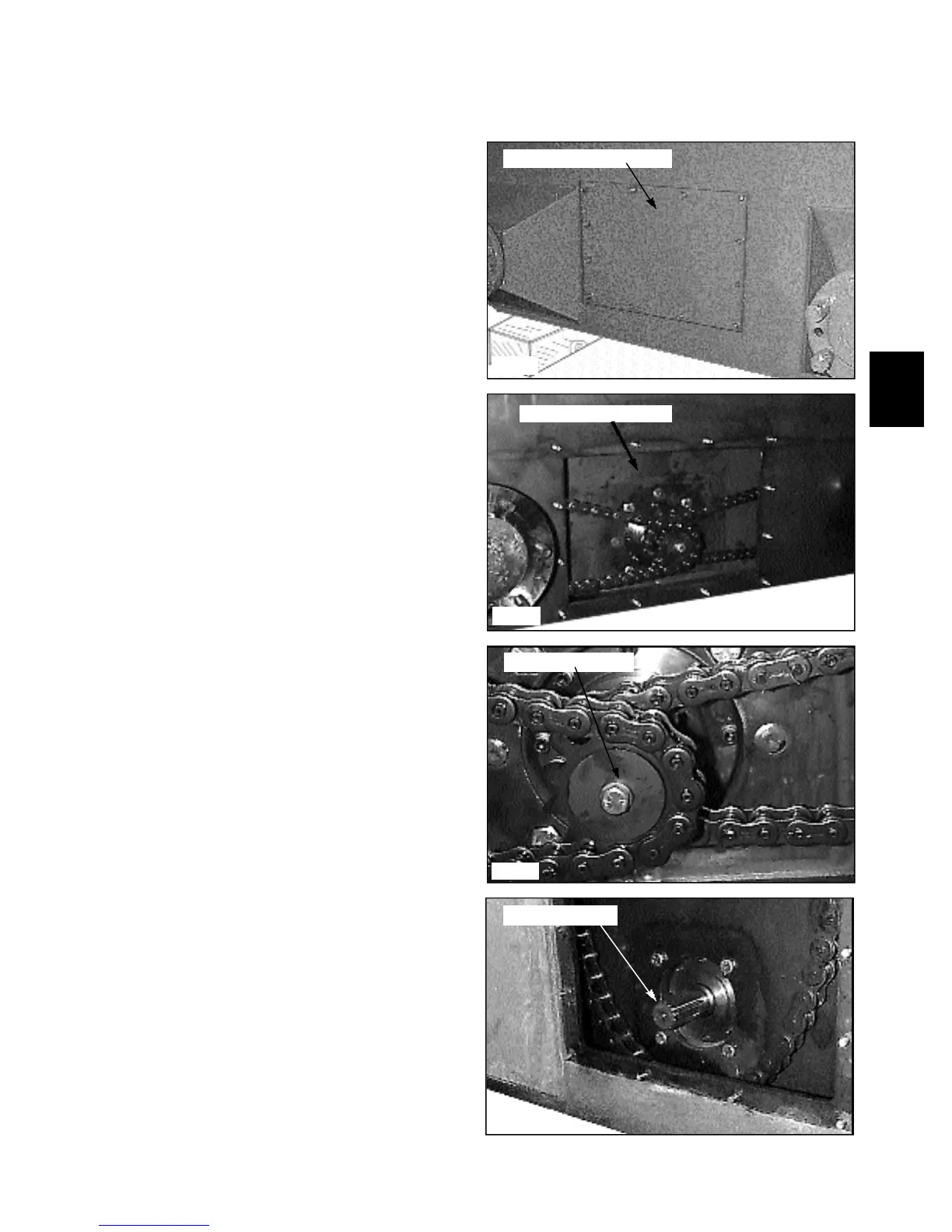

4 Disconnect both the front and rear drive chain con-

nector links.

C2073

Disconnect chain links

Remove inspection cover

C2424

Drive sprocket bolt

Remove sprocket

C2232

C2425

5 Remove the bolt retaining the drive sprocket to the

drive motor. (fig. C2425)

6 Pull the dive motor sprocket from the shaft. Inspect

the motor shaft for wear and replace motor parts if

required. (See Section 2.)

7 Replace the drive sprocket in the reverse order

above. Apply Loctite 242 (blue) to the drive sprocket bolt

and torque the bolt to 28 lbs / ft (38 nm).

8 Replace the connecting links with new, reseal the

inspection cover with silicone, and replenish the lubricat-

ing oil if needed.

Loading...

Loading...