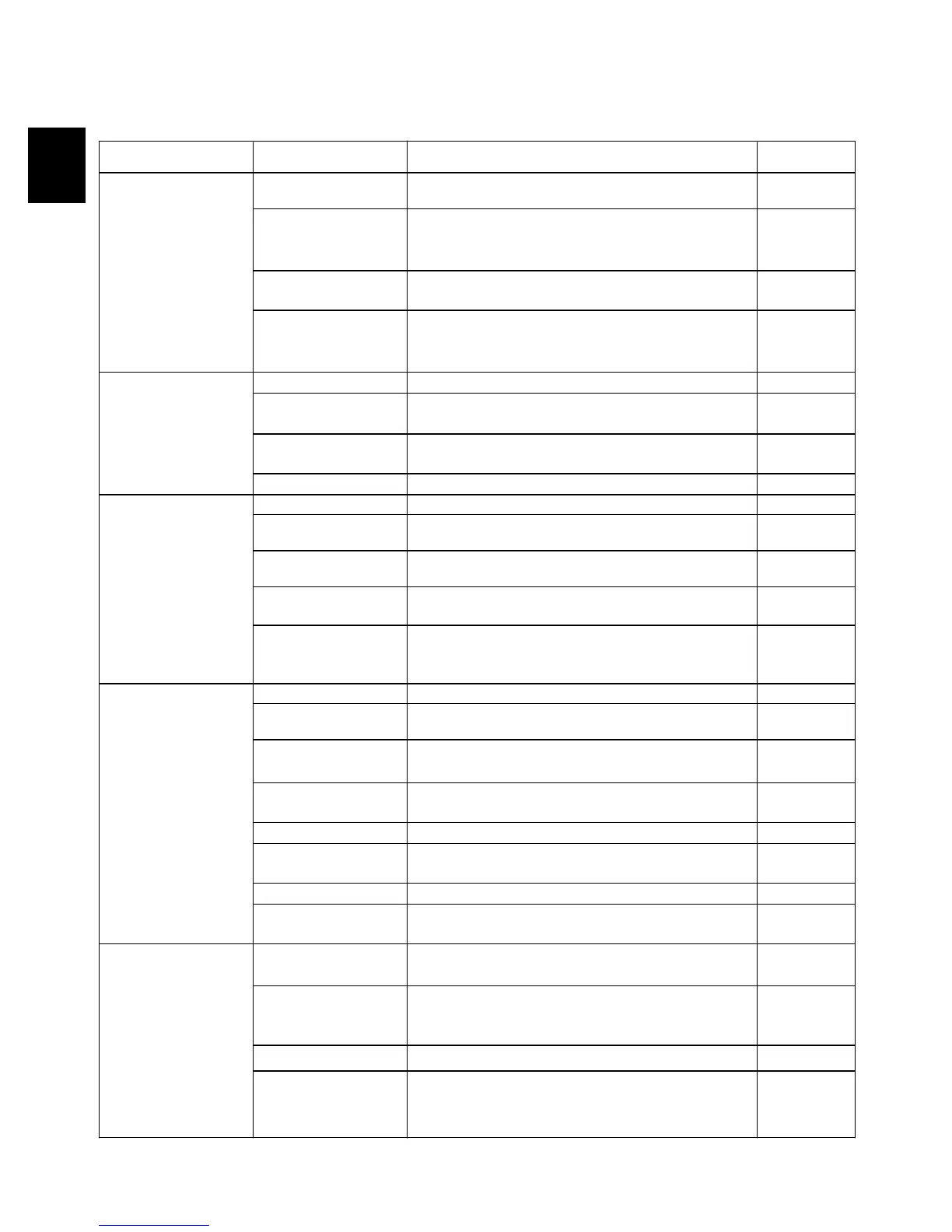

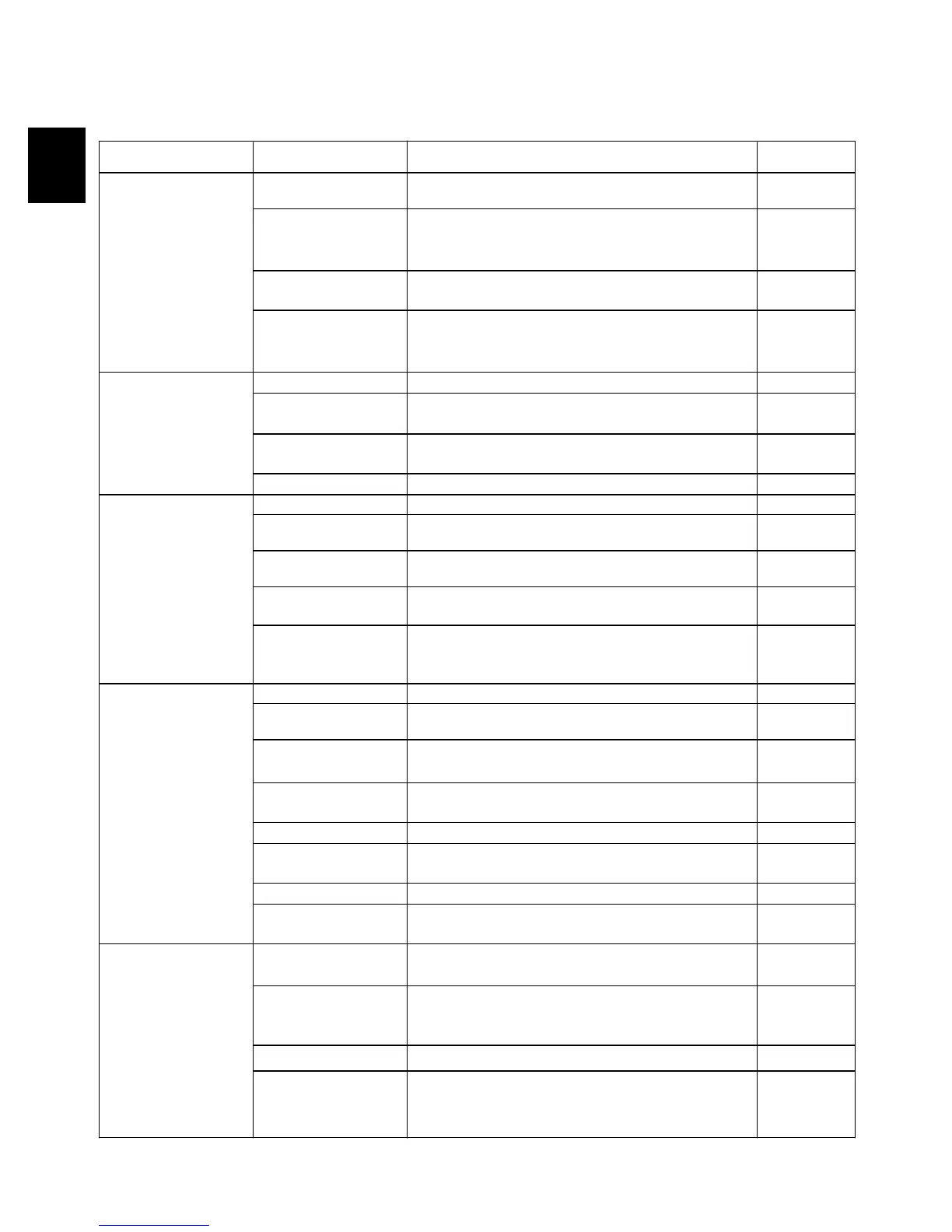

1-42

TROUBLE SHOOTING 1.8

Universal joint between

engine and tandem

pump failure.

Problem Cause Corrective Action Section

Loss of hydraulic

power (no flow from

the gear pump).

Reservoir low on oil. Check for leaks. Fill the reservoir to the proper level. 1.8

7.11

1.4 / 2.9

2.10

8

Inspect and replace the damaged parts as required.

Check for proper alignment.

Gear pump not

functioning.

Inspect and replace damaged parts.

Splined coupling

failure in the

hydrostatic pump

See the Sauer Sundstrand Repair Manual BLN 9992.

Loss of hydraulic

power (full flow from

gear pump).

Auxiliary hydraulics

engaged.

Disengage the switch.

Relief valve failure or

out of adjustment.

Electrical failure. Check fuse, switches and wiring.

4.9

Check pressure. Adjust or repair as required. 1.4

Hydraulic action jerky. Reservoir low on oil. Check for leaks. Fill the reservoir to the proper level. 1.8

Control linkages loose

or worn.

Inspect, adjust or replace parts.

4

Air in hydraulic

system.

Check for leaks between the oil reservoir and pump.

Load check valve not

functioning.

Inspect and replace damaged parts. 1.4

Control valve spool

spring return mech-

anism not functioning

Inspect and replace damaged parts. 1.4

Control locks engaged Check fuse, safety switches and valve lock parts.

1.4 / 8

Boom raises slowly at

full RPM

Reservoir low on oil. Check for leaks. Fill the reservoir to the proper level.

1.8

Control linkages loose

or worn.

Inspect, adjust or replace parts. 4

Auxiliary hydraulics

engaged.

Disengage the switch.

4.9

Lifting more than rated

capacity.

Reduce the load.

Engine RPM too low. Check engine RPM and reset.

7.11

Relief valve failure or

out of adjustment.

Check pressure. Adjust or repair as required. 1.4

Cylinder seal(s) failure.

Check seals.

Check seals.

1.5

1.5

Internal leakage in the

control valve.

Inspect the control valve and repair as required. 1.4

Hydraulic cylinders

will not support a load.

(leak down)

Control valve spools

not centering.

Check control linkage and control valve spool spring

centering devise.

1.4 / 4

External leak between

control valve and

cylinders

Inspect and repair.

1.4

Cylinder seal(s) failure

Load check valve not

functioning.

Inspect and replace damaged parts.

Loading...

Loading...