3-11

Axle Removal

AXLE ASSEMBLY 3.5

C2432

14 Retrieve the inside bearing, sprocket and axle sprock-

et keys from inside the final drive housing.

Please note the orientation of the axle sprocket on the

axle and in the housing. Front and rear sprockets have

a different offset.

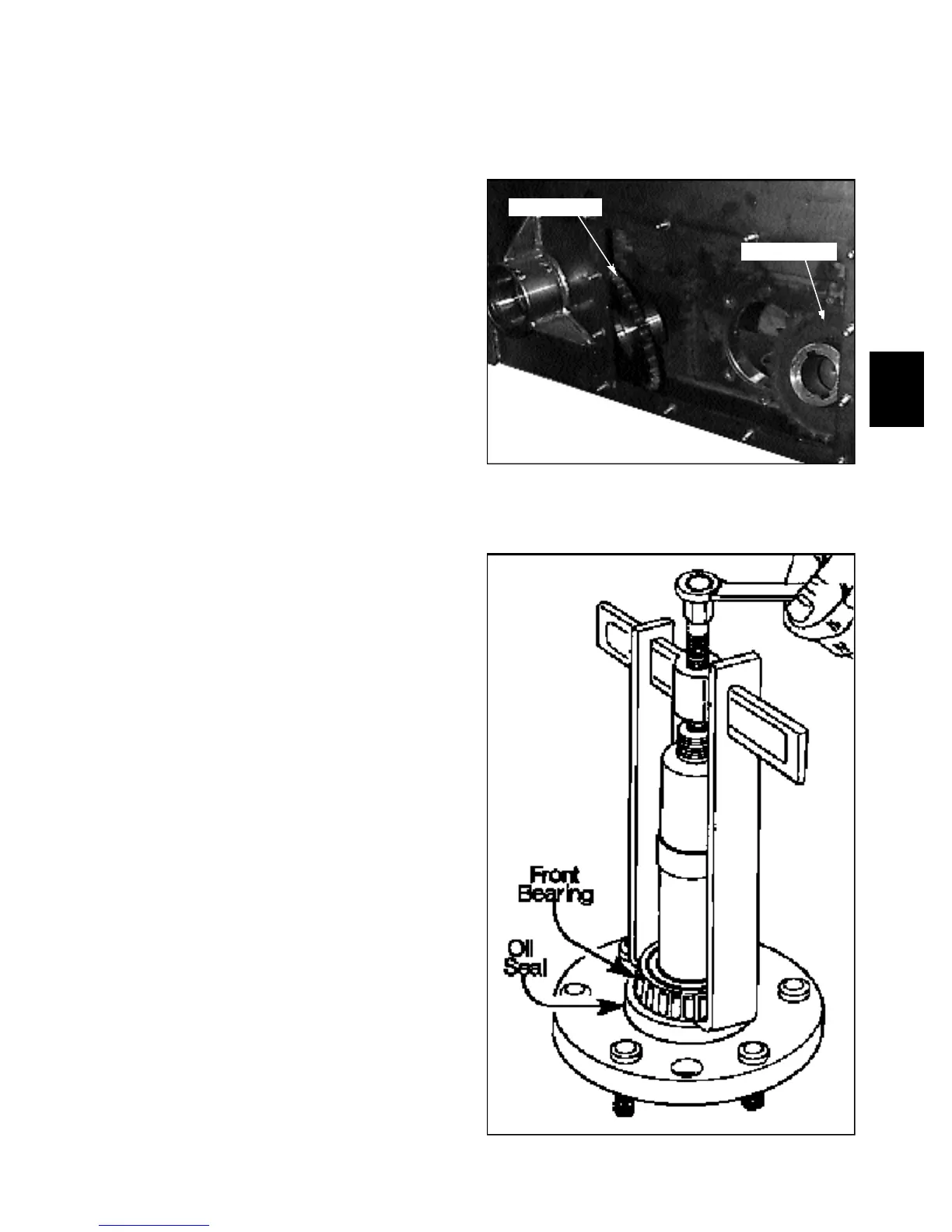

15 Using a bearing puller, remove the bearing still

pressed in place on the axle. (fig. C221)

16 Remove and discard the axle oil seal.

C221

1 Inspect the seal surface area for scaring, pitting or

nicks. Minor scratches may be removed using fine emery

cloth. Replace the axle if worn excessively.

2 Inspect the axle threads for damage. Replace axle if

the threads are non serviceable.

3 Inspect the axle keys for wear Replace as required.

4 Inspect the key way slots for wear. Replace the axle

and keys if the keys do not fit tightly into the key ways.

5 Replace any axle studs as required.

6 Inspect the axle sprocket for abnormal tooth wear

and the fit of the axle key in the sprocket key ways.

Replace the sprocket if necessary.

7 Inspect the bearing races in the final drive housing.

Replace them if necessary using a brass drift punch and

hammer. Cooling the races in a freezer will aid in easing

this procedure.

8 Replace the bearings if new races are installed or if

they are pitted or damaged.

Inspection

Rear sprocket

Front sprocket

Loading...

Loading...