1-32

Lift Cylinder Replacement

HYDRAULIC CYLINDERS 1.4

The following procedure will assist you in the cylinder

removal.

For removal of the boom cylinders:

1 Lower the boom arms, stop the engine and cycle the

controls to relieve any hydraulic back pressure in the

system. Lock the control in the float or detent position.

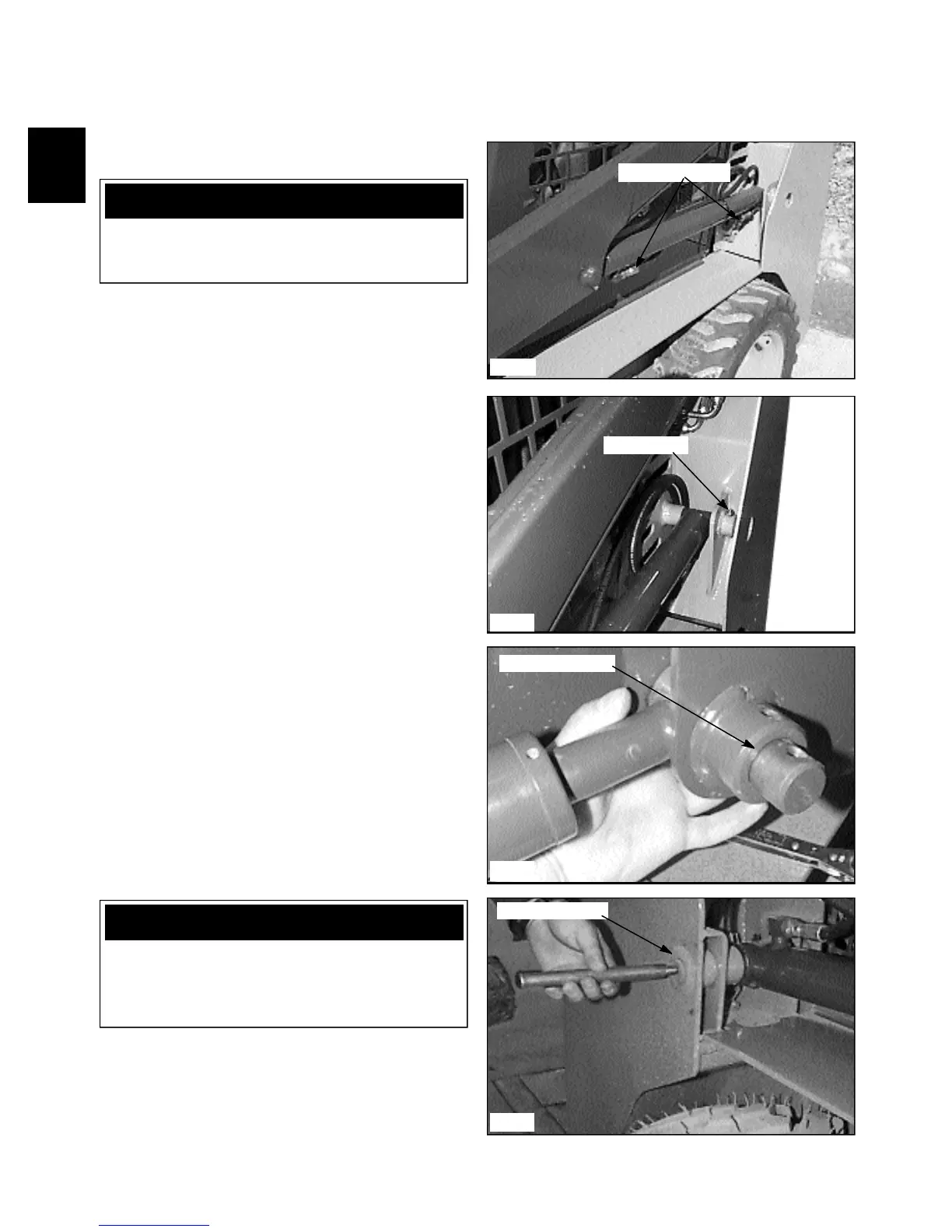

2 Remove the hydraulic hoses from the cylinder. (fig.

C2356) Cap all open ports and lines to prevent

contamination.

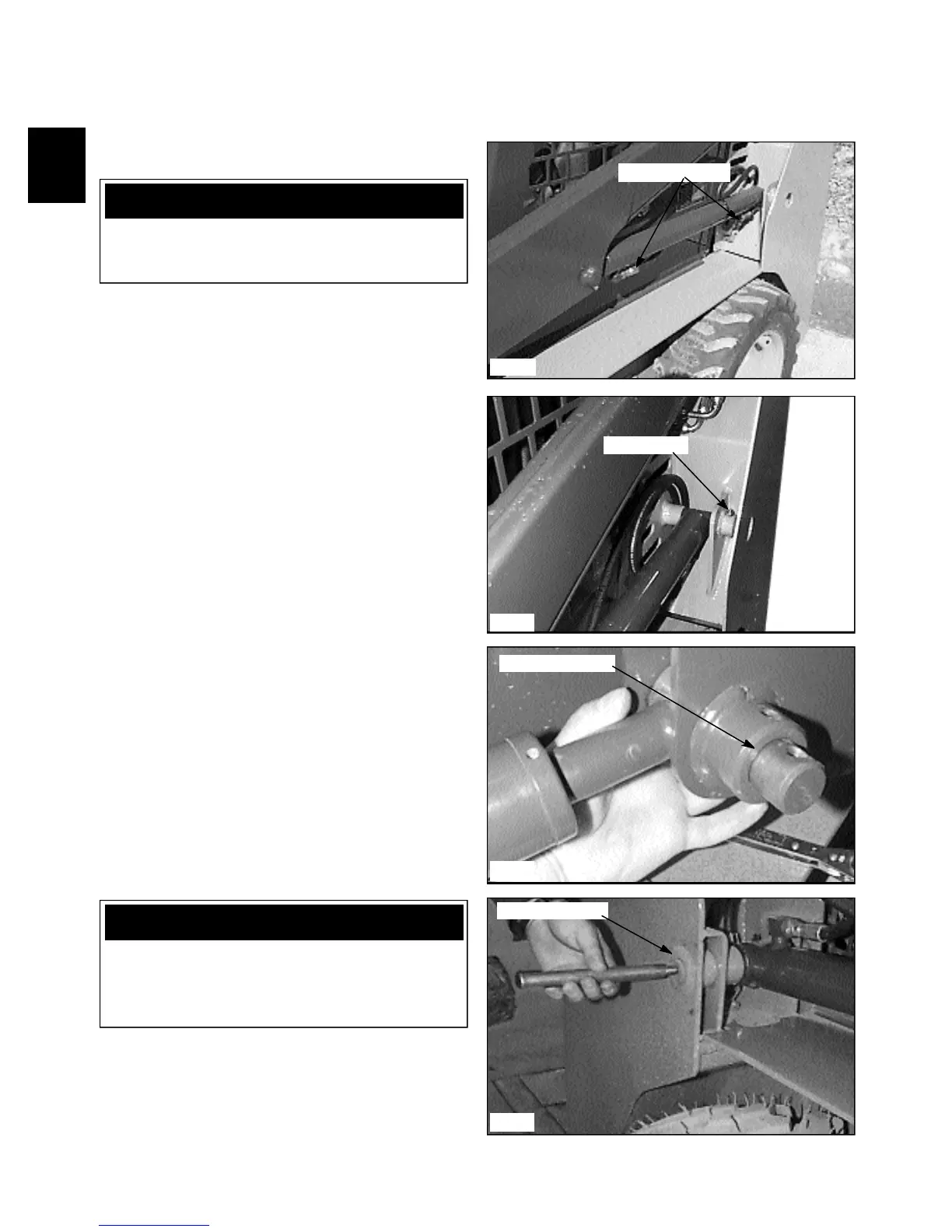

3 Remove the lock nut and bolt from both mounting

pins. (fig. C2413, C1864)

4 Remove the front pivot pin by pushing the pin out

from behind the boom arm, out toward you. (fig. C1876)

With an appropriate punch and hammer to prevent

brooming of the pin, remove the rear pin. (fig. C1877)

Brooming the pin makes it difficult to remove.

5 Remove the cylinder from the loader.

6 Upon replacement, inspect the pivot pins and

cylinder bushings for any wear. Replace if necessary.

Reverse order above for installation.

7 Upon start up, check for system leaks and replenish

the hydraulic reservoir as required.

C2356

C2413

Disconnect hoses

Remove bolt

C1876

C1877

Remove front pin

Remove rear pin

IMPORTANT

When making repairs to the hydraulic system, keep

the work area and parts clean. Use caps and plugs on

all open lines and ports.

WARNING

Use extreme caution when checking the hydraulic

system for leaks. Fluid under pressure can penetrate

the skin and cause serious injury. Never tighten or

repair hydraulic lines while the engine is operating.

Loading...

Loading...