3-16

TROUBLE SHOOTING 3.6

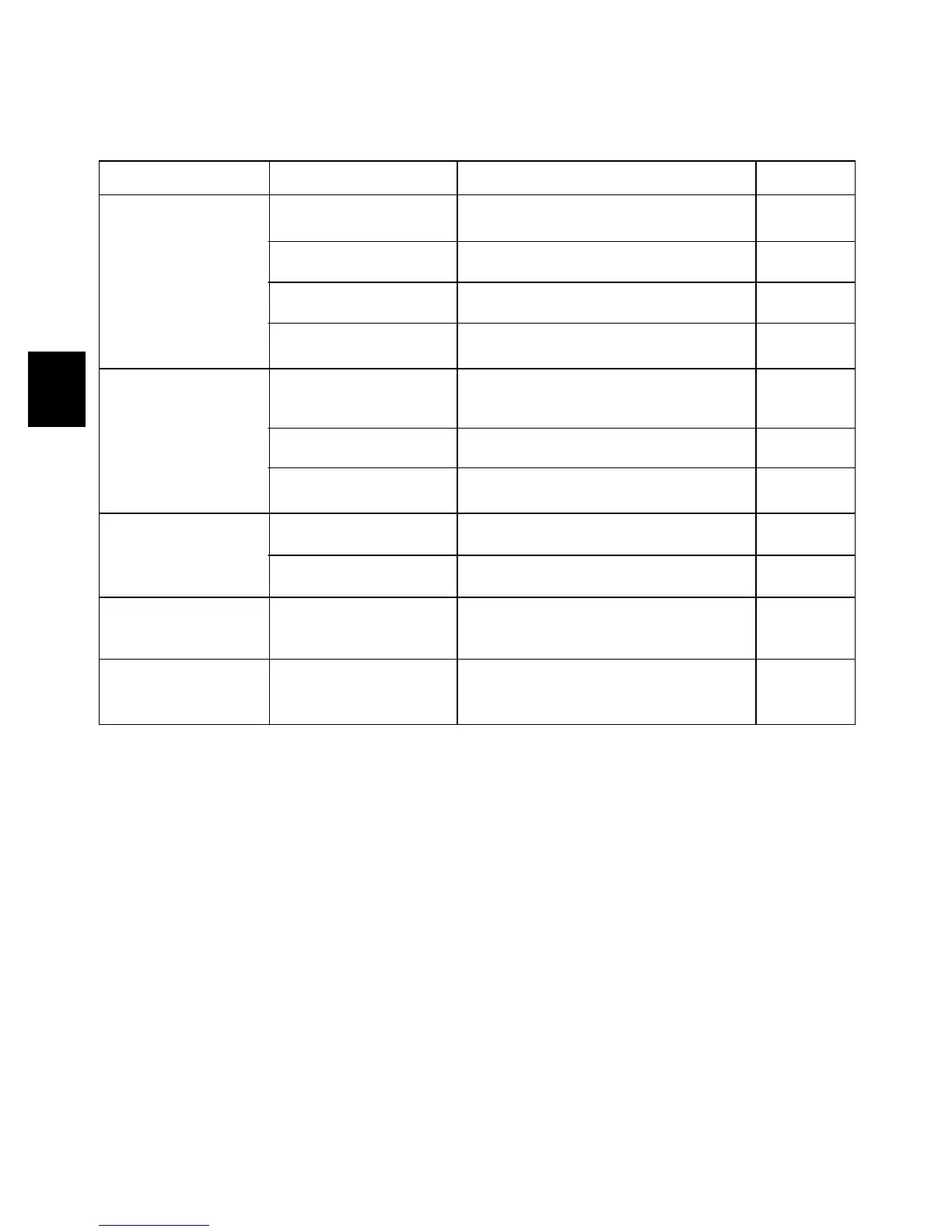

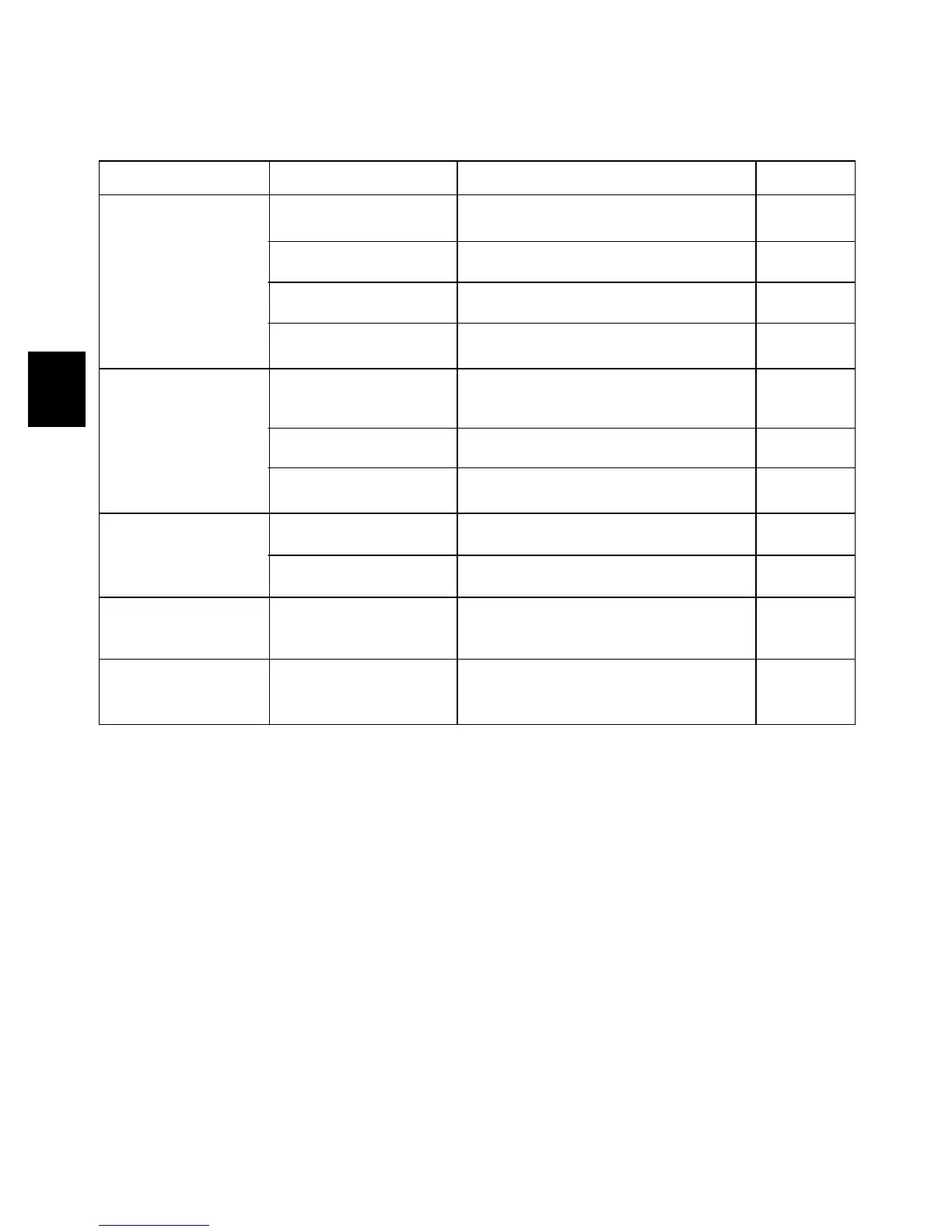

Problem Cause Corrective Action Section

Final drive noisy. Check oil level. Add 10W30 SE/CD oil to

correct level.

No lubricating oil. 3.2

Chain is loose. Adjust the chain tension. Check chain ten-

sion every 150 hours.

3.3

Check and adjust the bearing pe-load on the

axle bearings

Axle has too much end

play. (Bearing pre-load)

3.6

Chain tightener damage

or failure.

Inspect the chain tightener and repair if nec-

essary.

3.4

No drive on one side. Drive chain failure. Inspect the drive chain and connecting link.

Replace damaged parts. Check the chain

tension every 150 hours.

3.3

Drive motor sprocket

failure

Inspect the drive sprocket and splines.

Replace parts as required.

3.5

2

Refer to the hydrostatic drive section.

Diagnose and make repairs as required.

Drive motor or hydrostatic

system failure

2

Lubrication oil leaking

through the filler /

breather cap.

Lubricating oil level too

high.

Check the oil level. 3.2

Drive motor shaft seal

leakage.

Inspect and repair damaged parts. 2

Wheel nuts loose.Wheel studs shearing

off.

Replace the wheel studs. Check wheel

nut torque daily. Torque wheel nuts at

100 to 110 lbs/ft. (135 to 149 nm)

Replace the wheel studs. Check wheel

nut torque daily. Torque wheel nuts at

100 to 110 lbs/ft. (135 to 149 nm)

3.6

Wheel nuts over tight-

ened.

Wheel stud threads

stripped.

3.6

Loading...

Loading...