When installing a new control valve, always inspect the

exterior for shipping or other damage, such as bent

brackets, broken spring return caps or damaged spool

lock mechanism. Repair all damaged parts before

installation to the loader.

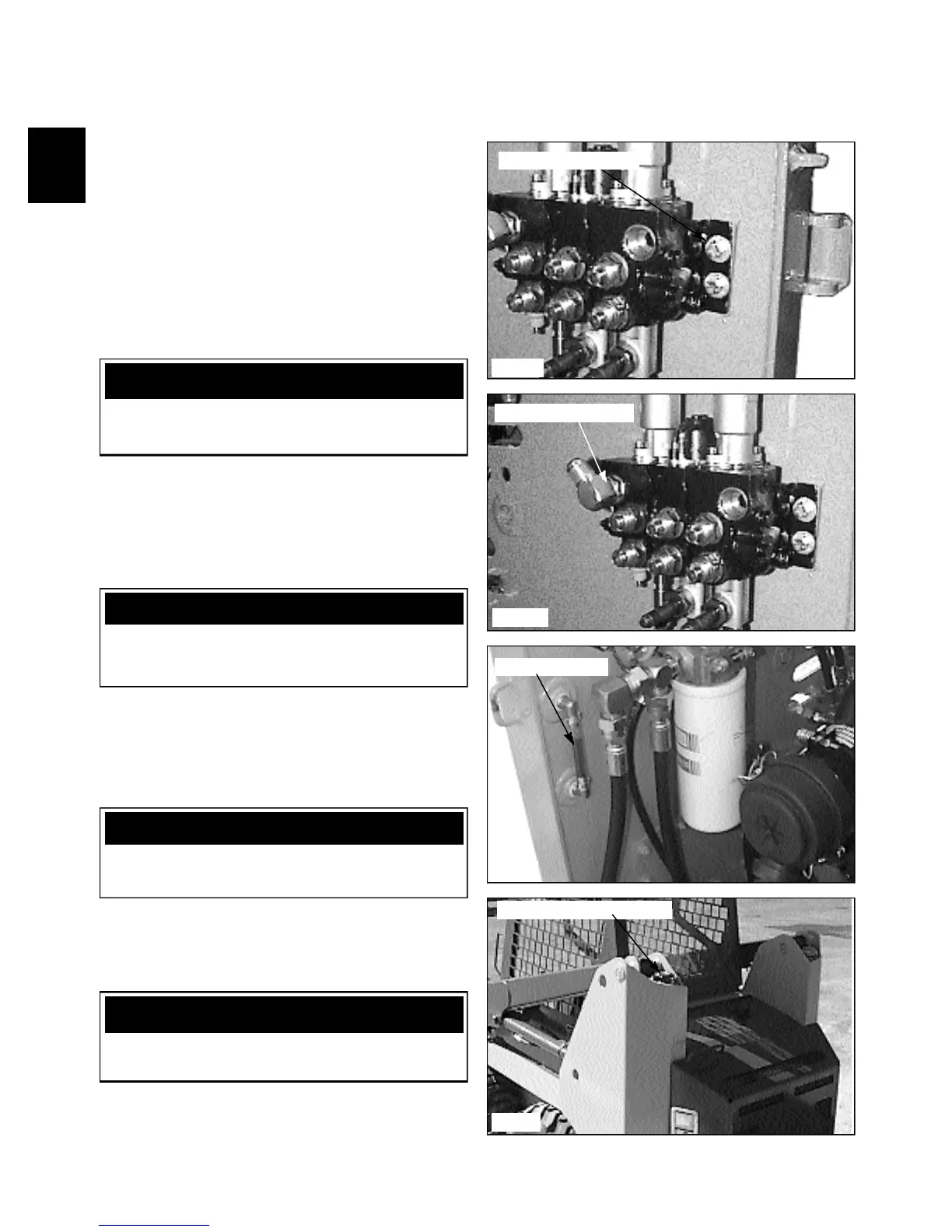

1 Mount the control valve to the loader. (fig. C2324a)

2 Connect the control cables to the spools.

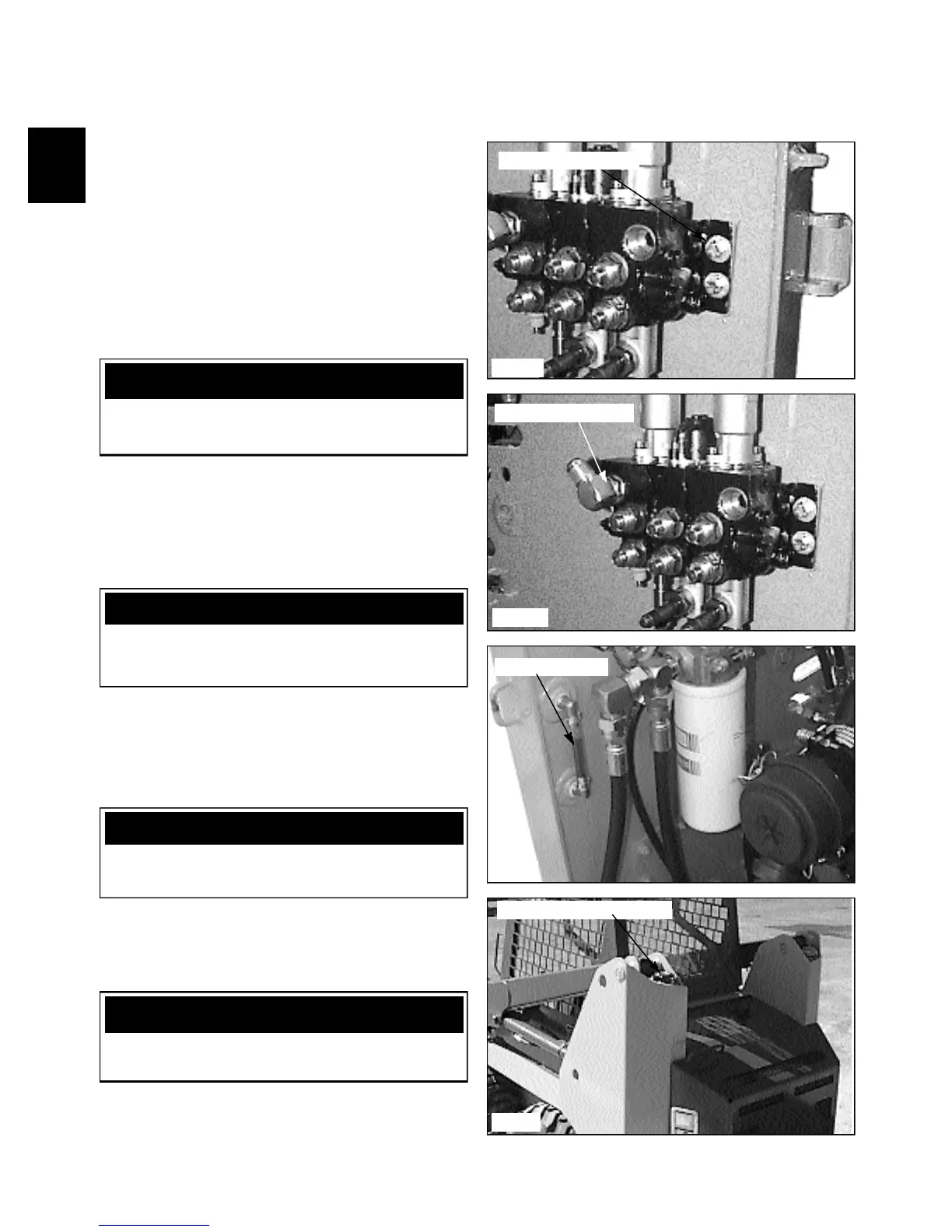

3 Connect the various hydraulic lines to their proper

ports. (fig. C2324b).

4 Connect the solenoid coils to the control valve locks.

Apply a drop of Loctite 242 (blue) to the knurled

retaining nut.

5 Verify fluid level in th hydraulic oil reservoir. (fig.

C2354). Top off as required to bring oil level to

approximately half way in the site gauge.

1-10

CONTROL VALVE 1.3

C2324a

Control valve fittings

C2354

C2355

Check fluid level

Replenish fluid as required

Install valve to mount

C2423b

IMPORTANT

Follow the hydraulic fitting torque chart in Section

1.10 when connecting fittings and lines.

WARNING

Use extreme caution when checking the hydraulic

system for leaks. Fluid under pressure can penetrate

the skin and cause serious injury.

WARNING

All safety switches must be connected and

functioning to prevent possible operator injury.

Control Valve Installation

WARNING

Verify the relief valve pressure setting after replacing

or servicing the control valve.

Loading...

Loading...