1-6

GEAR PUMP 1.2

Start the gear pump removal procedure by removing any

attachment, raising the boom arms and engaging the

boom support pins. Shut off the engine.

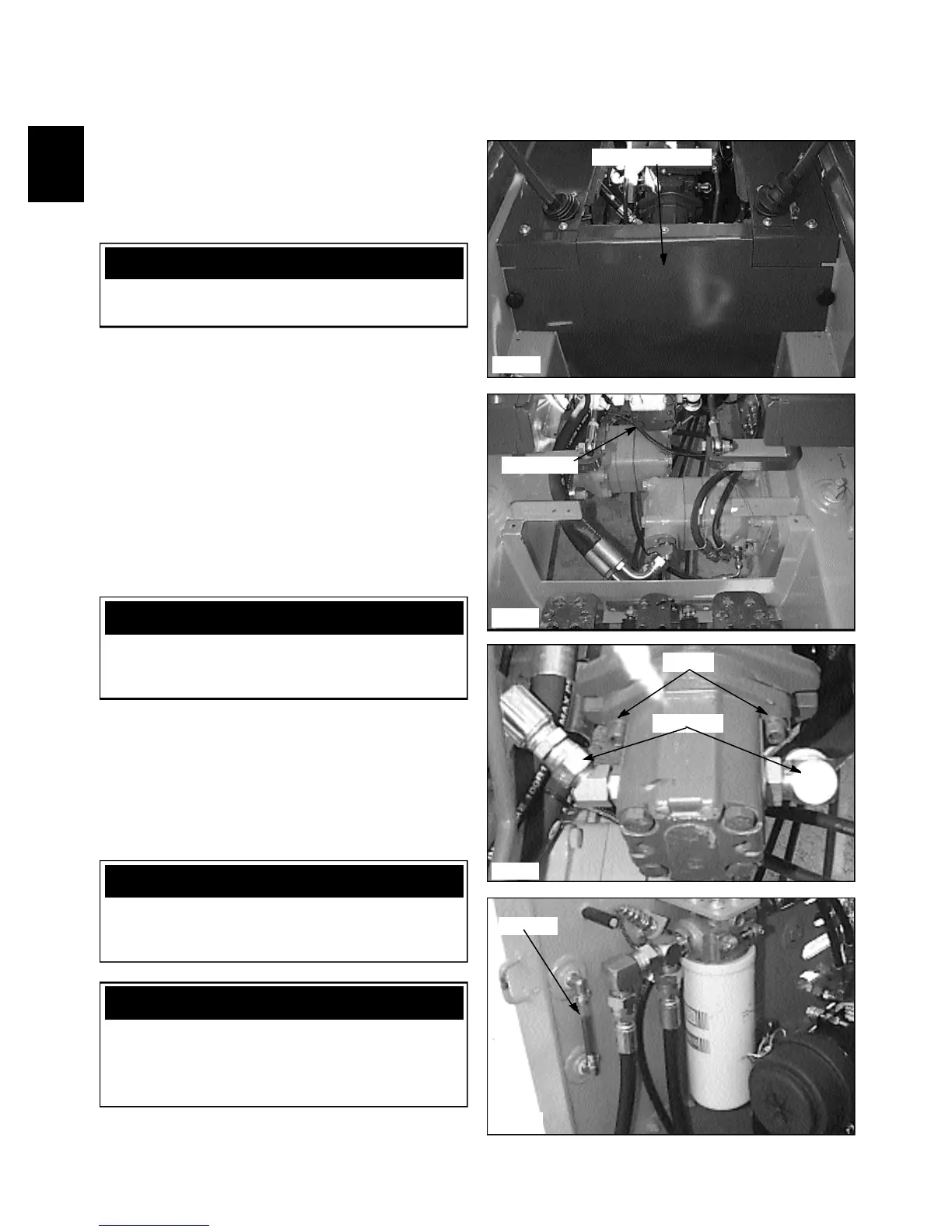

1 Remove the seat and hydrostatic shield. (fig. C2358,

C2360)

2 Attach a vacuum system to the hydraulic oil reservoir

filler location. Or drain the oil reservoir. Seal the threads

on the drain plug, if removed, with teflon tape or a liquid

form of pipe sealant before installing.

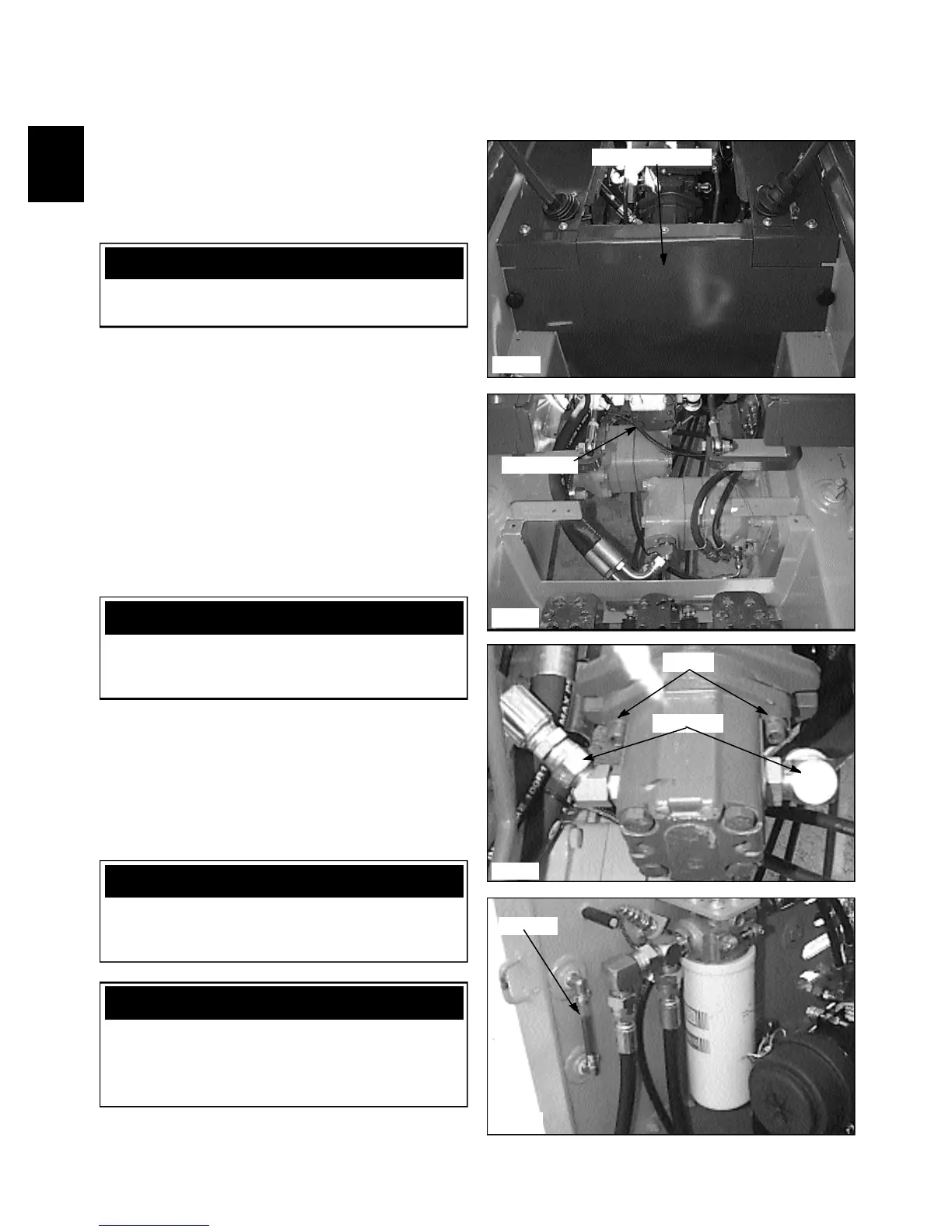

3 Disconnect the hydraulic hoses from the gear pump.

(fig. C2353) Remove the pump fittings. Cap all open

hoses to prevent contamination. After capping ends you

may unhook vacuum system from oil reservoir.

4 Remove the 2 bolts holding the gear pump to the

hydrostatic tandem section. (fig. C2353) Remove the gear

pump. Check the seal. Replace if required.

5 Replace gear pump in reverse order.

6 Start the engine and check for leaks. Do not use your

hands to find leaks.

7 Check the fluid level in the hydraulic oil reservoir

and replenish as required. (fig. C2354)

8 Follow the Start Up Procedure upon completing

repairs. See next page.

C2358

C2360

C2353

C2354

Gear pump

Screws

Hydrostatic shield

Oil level

Replacement

WARNING

To prevent personal injury, never work under the

boom arms without the boom supports engaged.

WARNING

Use caution when dealing with fluid under pressure.

Escaping fluid under pressure can penetrate the skin

and cause serious injury.

IMPORTANT

If gear pump replacement is being done because of

failure, the hydraulic system and oil should be

checked for contamination. See section 2.7.

IMPORTANT

When making repairs to the hydraulic system, keep

the work area and parts clean. Use caps and plugs on

all open lines and ports. Follow the torque chart

when tightening lines and fittings.

Hyd. lines

Loading...

Loading...