2-29

DRIVE MOTOR 2.11

Removal

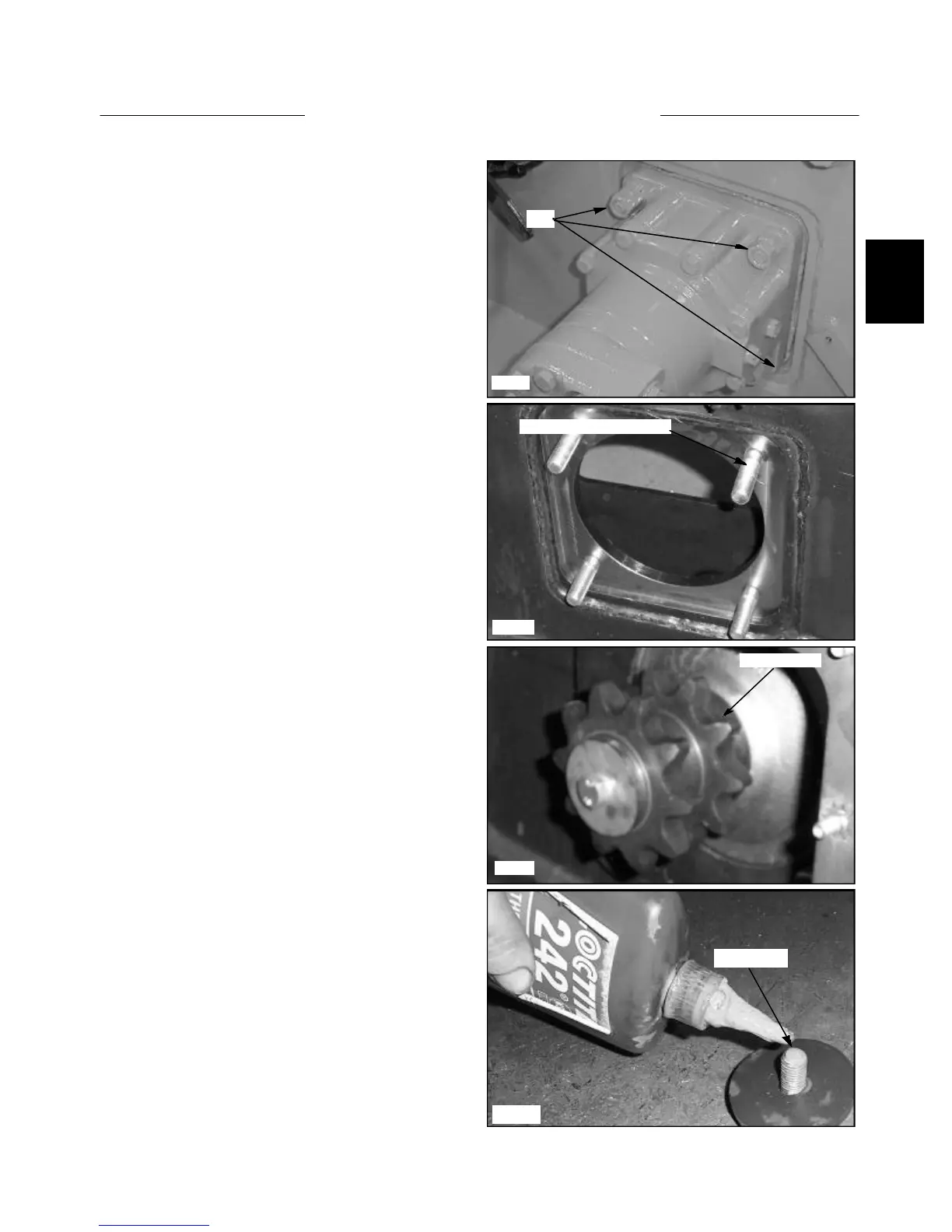

12 Remove the jam nuts, mounting nuts and lock wash-

ers from the 4 mounting bolts retaining the drive motor to

the final drive housing. (fig. C3491) Hold the head of the

bolts from inside the final drive housing. (fig. C3492)

13 Remove the drive motor. Seal the drive motor with

silicone upon reassembly.

14 Upon reassembly torque the 4 mounting nuts to 80

lbs / ft.

15 If the drive motor replacement is being performed

because of major parts failure, such as geroter damage,

the hydraulic system must be checked for contamination

and flushed if necessary as outlined in Section 2.7.

C3491

Nuts

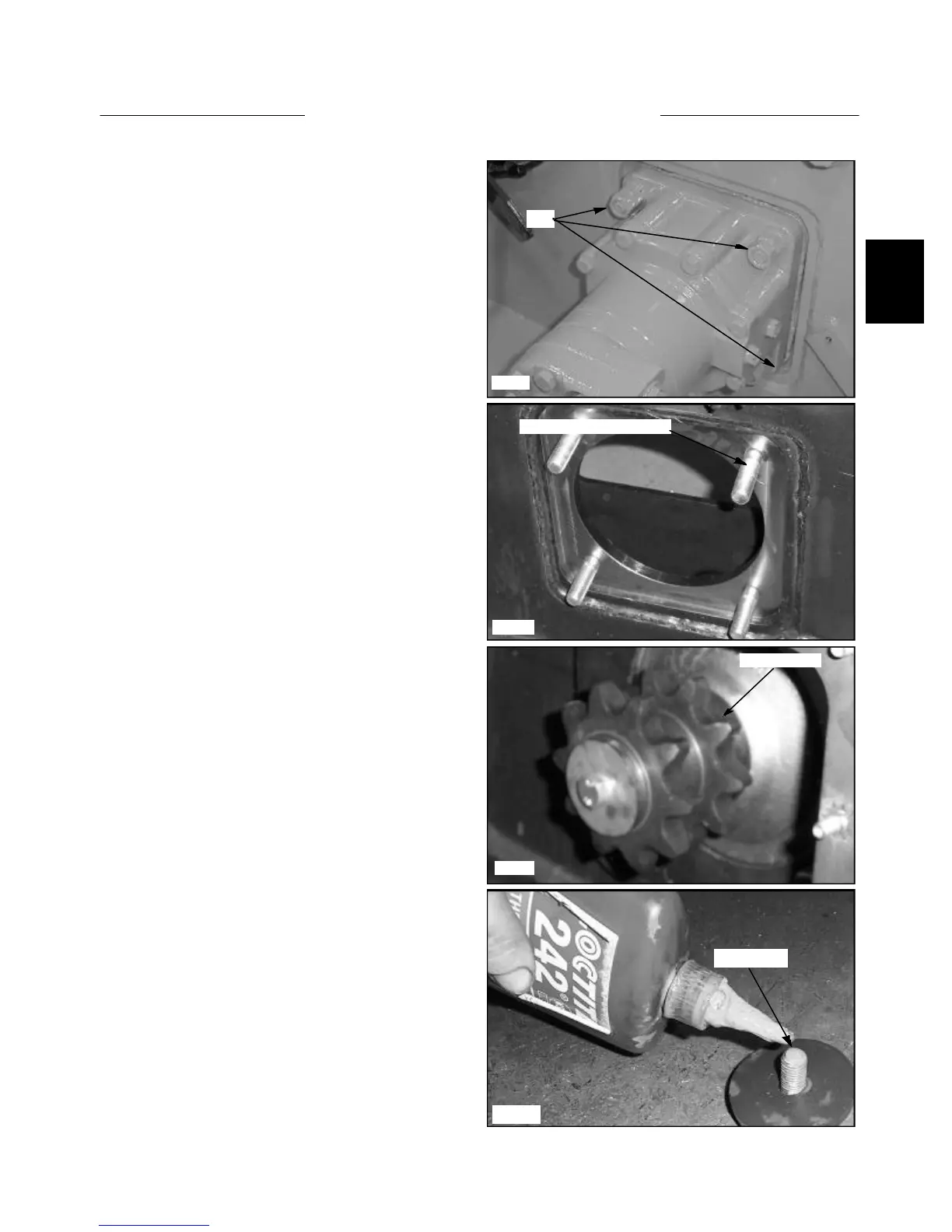

C3767

C3493

Apply loctite

C3492

Torque motor mounting bolt

Drive sprocket

17 Install the sprocket, machined washer, lock washer

and bolt. Apply Loctite 242 (blue) to the threads of the

bolt before torquing (fig. C3767) and torque the bolt to 40

lbs / ft. (54 nm).

16 If you are installing a new drive motor, remove the

drive motor sprocket and bolt if you wish to reuse the

sprocket. (fig. C3493)

Loading...

Loading...