CHAPTER 3– INSTALLING THE MULTILOAD II/RCUII EXL

24 MultiLoad II/ RCU II Explosion Proof Lite (EXL) Installation Guide - Part # 6070

DC Powered Models

The MultiLoad II/ and RCU II is optionally available with a 24 Vdc power supply. The power source

used to supply the MutliLoad II/RCUII must be rated 9 – 30 Vdc SELV, Limited Energy (Class 2). The

rated supply input current is 600mA. The supply should be protected by a 1.5 Amp fuse.

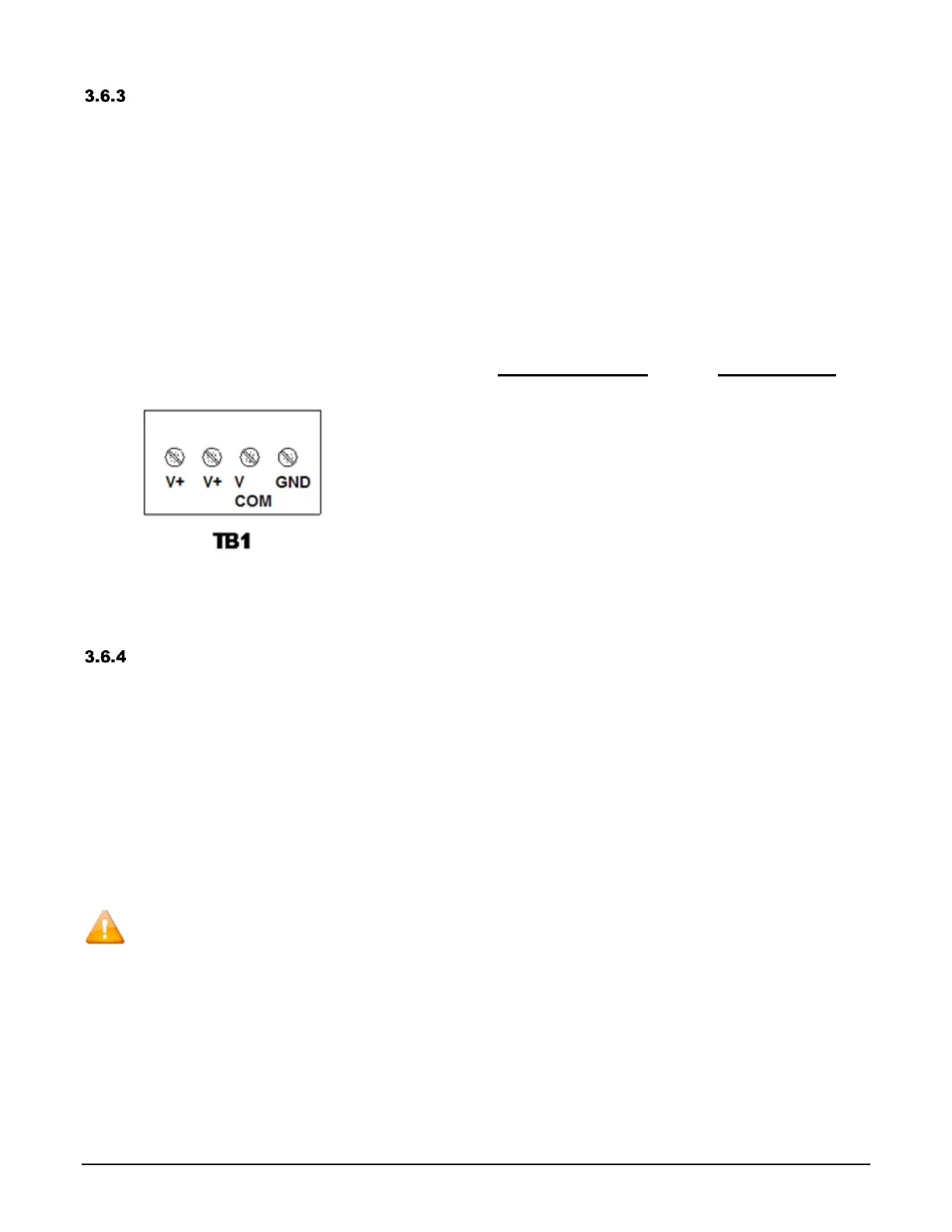

The 4-position terminal block is located in the right-hand corner of the power supply/communication

board. The left-most terminal position is a spare and will not be used.

Figure 3.4 DC Power Connections

Wiring guidelines for using 24 Vdc power

supply:

Equipment Grounding

A safety ground should be attached to terminal block TB1 (on both ac and dc input power models) to

maintain electrical safety in the event of a fault condition. Follow the terminal block wiring instructions

in section 3.6. Keep the required tightening torque in mind (section 3.5).

The external ground connection is not provided for the attachment of the protective conductor (the

safety ground). Rather, it is provided only as a supplemental bonding connection where local

authorities permit or require such a connection: for example, as a means of equipotentiality. The wire

connection is on the bottom right exterior surface. The following wire sizes may be used: 10 AWG

(5.26 mm

2

) or 11 AWG (4.17 mm

2

).

Do not connect the power supply dc common to earth ground.

Loading...

Loading...