Chapter 1

7

UM10349_PCNC1100_Manual_0916A

Preface

Resolution, Accuracy, and Repeatability

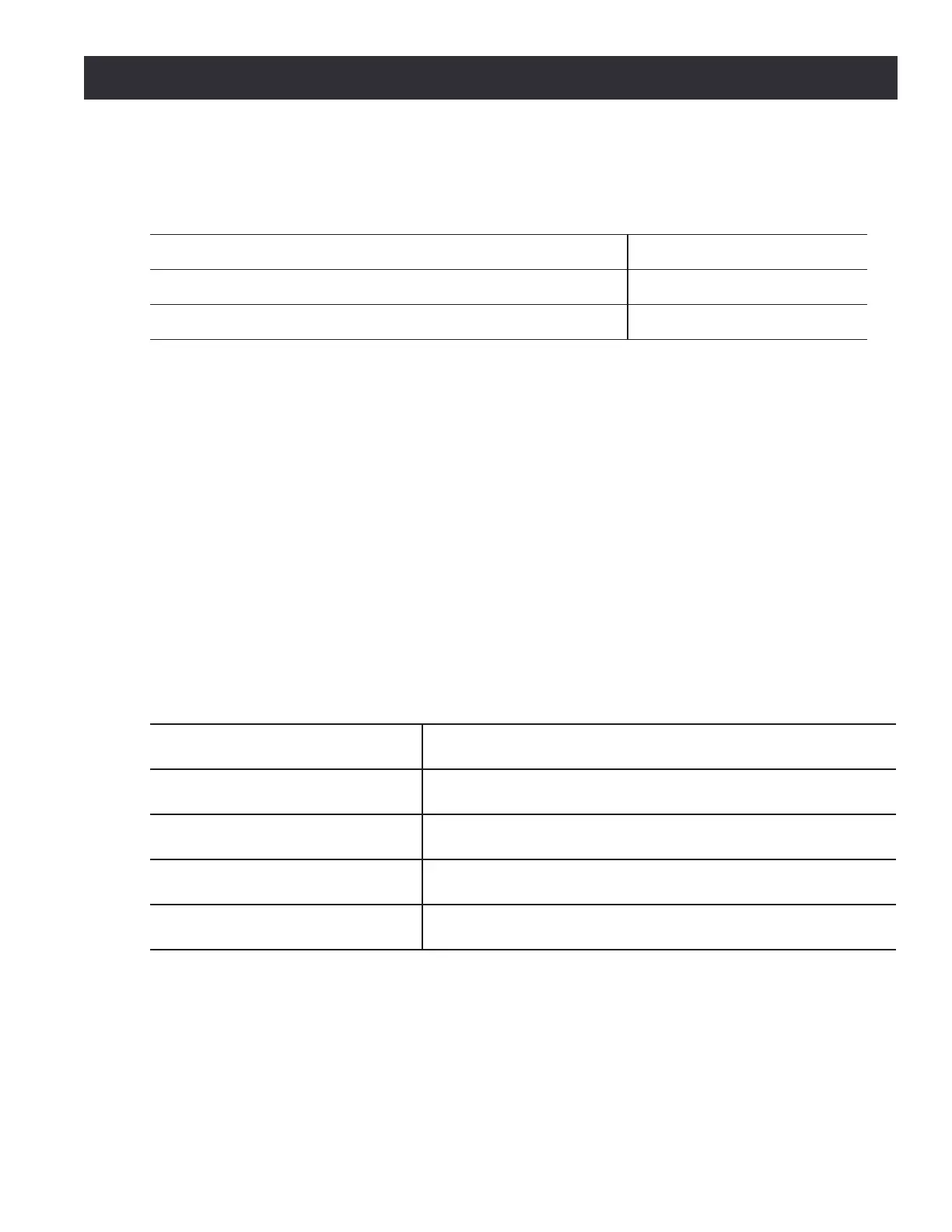

The following table summarizes resoluon, accuracy, and repeatability of PCNC mills as delivered.

Resolution of Motion (minimum discrete positional move) 0.0001”

Ball Screw Positional Accuracy ≤ 0.0006” per foot

Combined Positional Accuracy

1

≤ 0.0013” per foot

1

Includes addional contribung factors such as compressibility of bearings, ball screw windup, fricon, etc.

Each PCNC Mill ships with a Cercate of Inspecon. This report details quality assurance

measurements performed at the factory by a Tormach quality assurance team member on each mill

prior to shipping.

A sample cercate of inspecon and more informaon on quality assurance measurements is

available at: hp://www.tormach.com/quality_overview.html

In pracce, accuracy and repeatability are heavily inuenced by the techniques used by the

machinist. A skilled machinist can oen deliver accuracy that exceeds the accuracy specied by

the manufacturer, while an inexperienced machinist may have diculty delivering the expected

accuracy. With this understanding, Tormach cannot predict operator accuracy. Nevertheless, the

accuracy specied by the manufacturer remains an important reference point.

Nomenclature

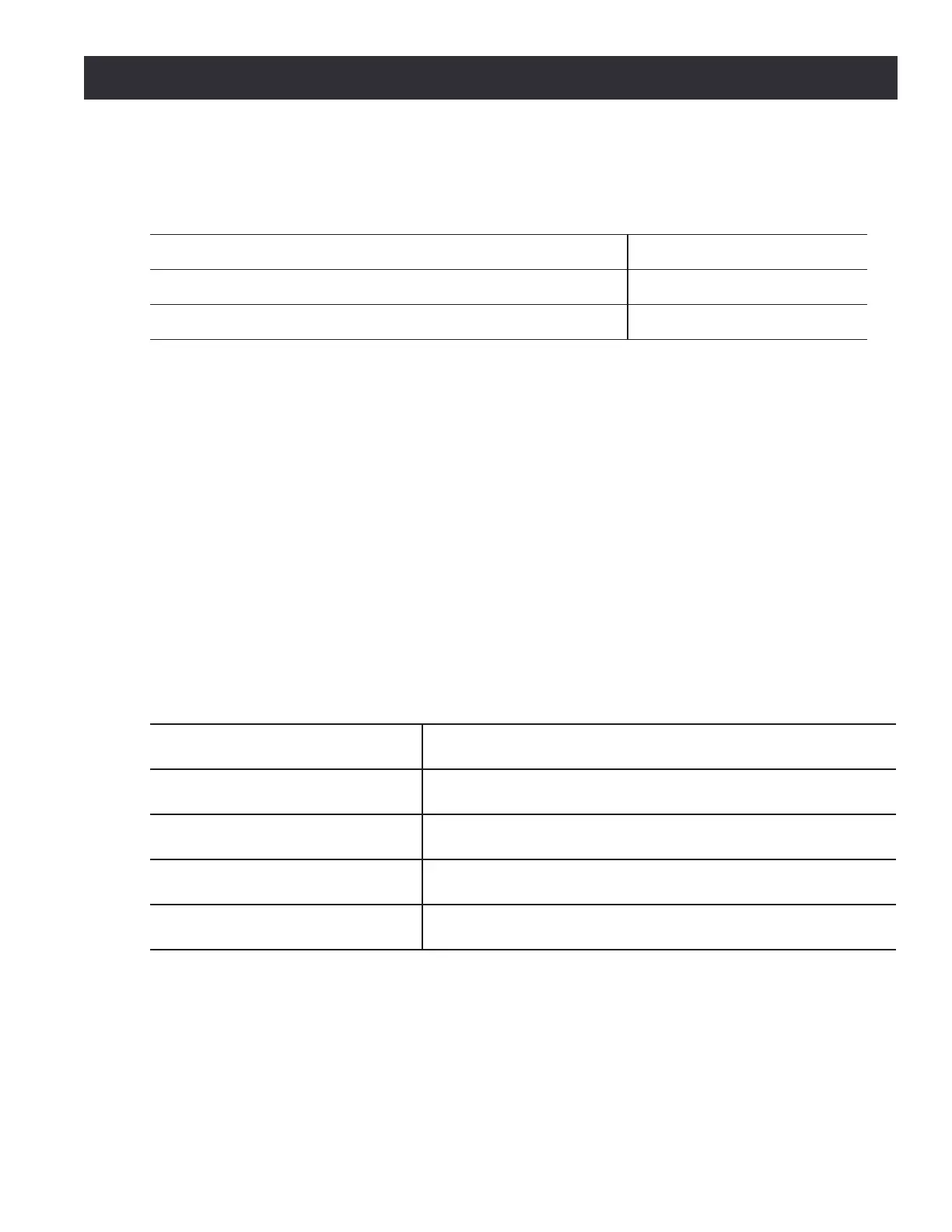

This manual uses the following typographical nomenclature.

Soware Control

Refers to a Software Control, i.e., an on-screen button

Hardware Control

Refers to a button or switch on mill’s Operator Panel

G-code (e.g., G01X34.8)

Used to show G-code programs

Key name (i.e., Enter)

Tells you to press the indicated key

Buon name (i.e., Stop)

Tells you to press the indicated button

Loading...

Loading...