Rev. B

Workman 1100/1110/2100/2110 Page 6 – 7 Electrical System

Component Testing

For accurate resistance and/or continuity checks, elec-

trically disconnect the component being tested from the

circuit (e.g. unplug the ignition switch connector before

doing a continuity check on the switch).

NOTE: See the Briggs and Stratton Repair Manual

for 4 Cycle, V–Twin Cylinder, OHV Head Engines or

the Kohler Service Manual for Command Pro CS Se-

ries Engines for additional component testing informa-

tion.

CAUTION

When testing electrical components for continu-

ity with a multimeter (ohms setting), make sure

that power to the circuit has been disconnected.

Ignition Switch

Two types of ignition (key) switches have been used on

the Workman 1100,1110, 2100, and 2110.

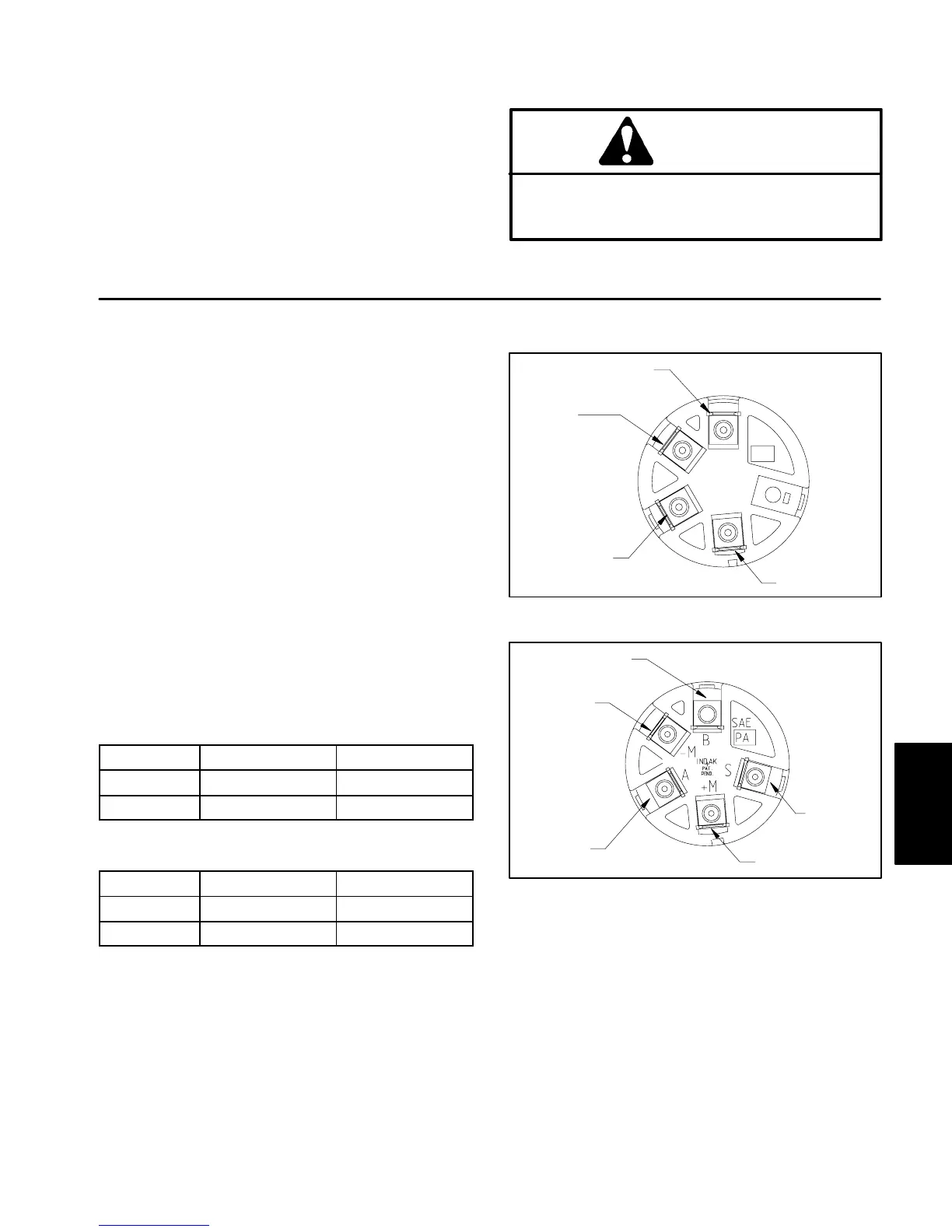

Early production switches had four switch terminals and

two key positions (OFF and RUN). The switch terminals

are marked as shown in Figure 3.

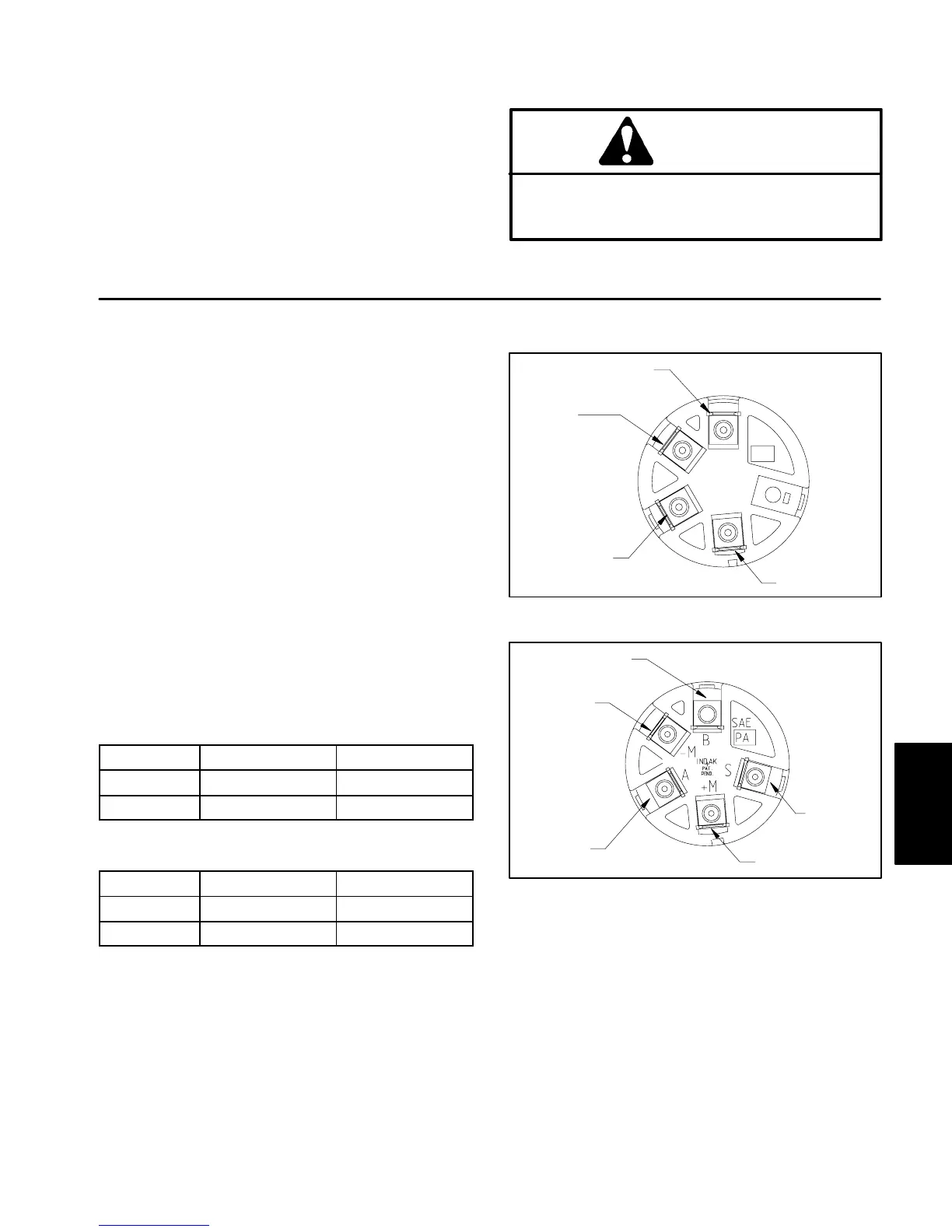

Later production switches had five switch terminals and

three key switch positions, but only two or those posi-

tions are used (OFF and RUN). The switch terminals are

marked as shown in Figure 4.

Testing

The circuitry of the ignition switch is shown in the charts

below. With the use of a multimeter (ohms setting), the

switch functions may be tested to determine whether

continuity exists between the various terminals for each

key position. Verify continuity between switch terminals.

1. For 2 position switch (Fig. 3):

POSITION

CIRCUIT “MAKE” AMPS

OFF +M + –M 1

RUN 1 + 2 15

2. For 3 position switch (Fig. 4):

POSITION

CIRCUIT “MAKE” AMPS

OFF +M + –M 1

RUN A + B 15

TERMINAL 1

TERMINAL 2

TERMINAL +M

TERMINAL –M

SAE

PA

1

+M

–M

2

SAE

Figure 3

END VIEW

2 POSITION SWITCH

Figure 4

END VIEW

TERMINAL B

TERMINAL –M

TERMINAL A

TERMINAL S

TERMINAL +M

3 POSITION SWITCH

Electrical

System

Loading...

Loading...