Workman 1100/1110/2100/2110Page 7 – 18Chassis, Wheels, and Brakes (Rev. B)

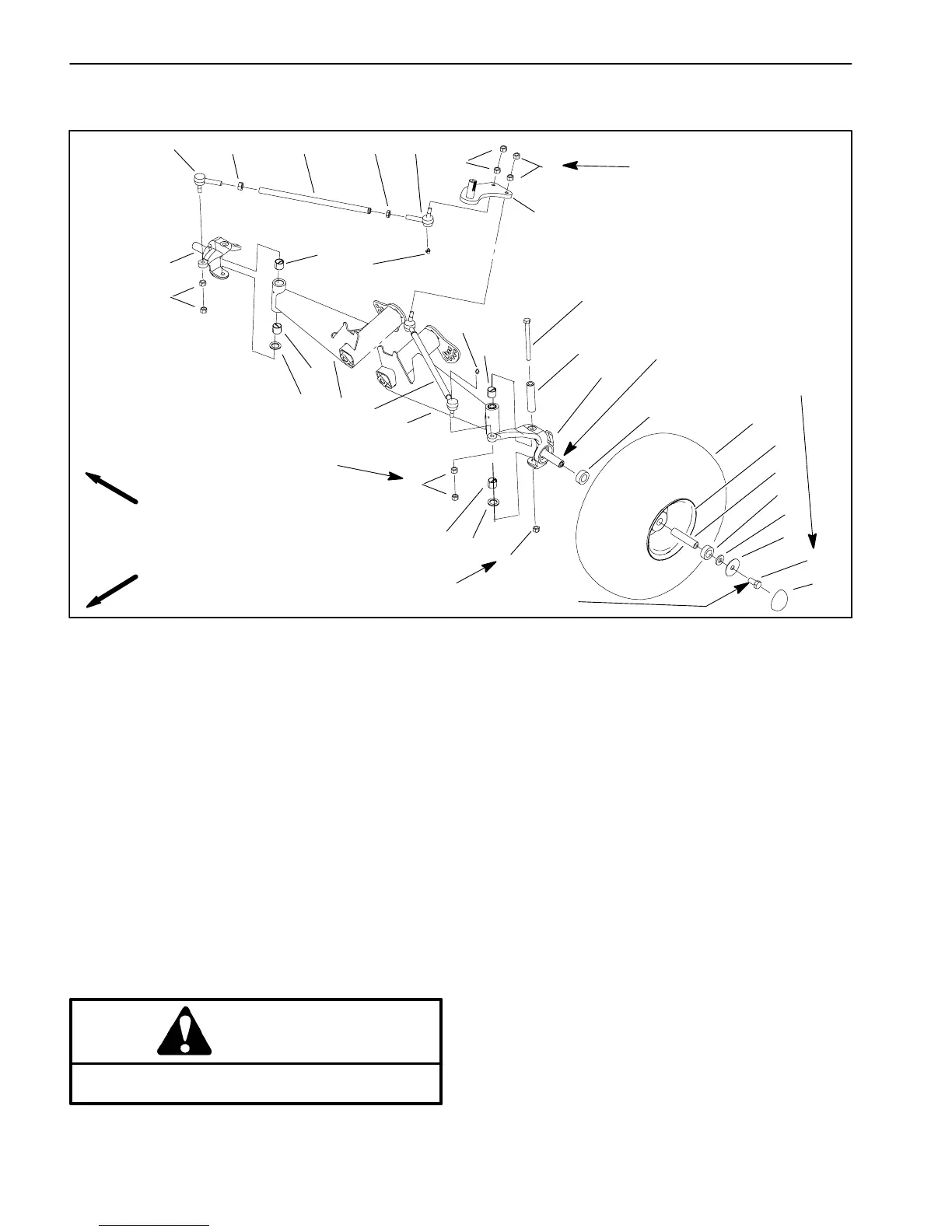

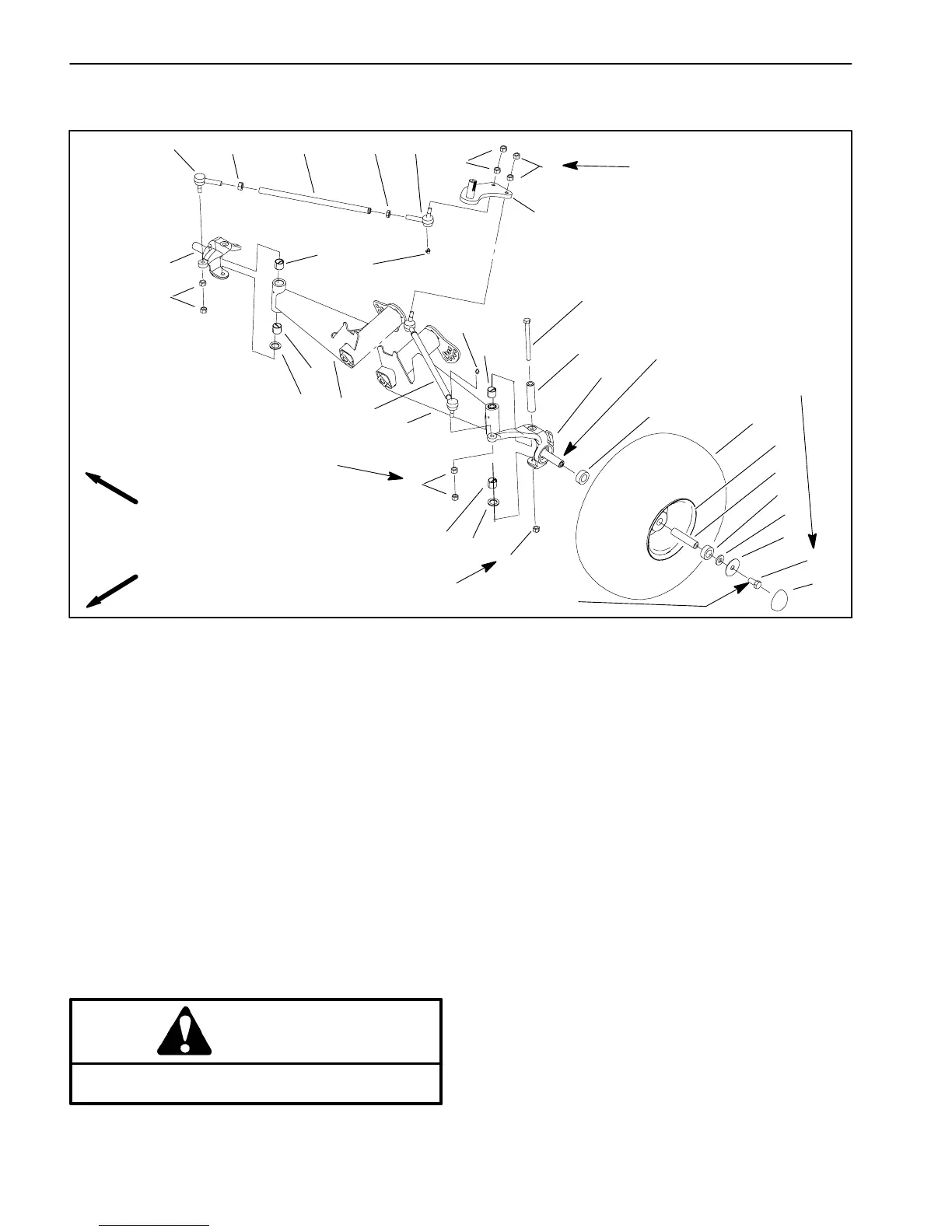

Lower Steering and Front Wheels (Workman 1100 and 2100)

1. Tire

2. Front wheel

3. Plastic dust cap

4. Cap screw

5. Large flat washer

6. Flat washer

7. Bearing

8. Spacer

9. Spindle (LH)

10. Lock nut

11. Thrust washer

12. Cap screw (king pin)

13. Jam nuts

14. Tie rod assembly

15. Ball joint (RH thread)

16. Jam nut (RH thread)

17. Tie rod

18. Jam nut (LH thread)

19. Ball joint (LH thread)

20. Pitman arm

21. A–arm (LH)

22. A–arm (RH)

23. Kingpin sleeve

24. Bushing

25. Spindle (RH)

26. Grease fitting

Figure 12

FRONT

RIGHT

10

25

15

26

26

12

9

16

17

18

19

13

1

6

5

4

3

2

8

7

14

13

24

24

22

21

11

20

13

13

7

23

Antiseize

135 to 165 ft–lb

(183 to 224 N–m)

20 to 25 ft–lb

(27 to 34 N–m)

75 to 100 ft–lb

(102 to 136 N–m)

24

24

11

20 to 25 ft–lb

(27 to 34 N–m)

lubricant

Thread locking

compound

NOTE: Both front wheels (2) have two bearings (7) and

one spacer (8).

NOTE: Both tie rod assemblies (14) consist of the fol-

lowing parts: ball joints (15 and 19), jam nuts (16 and

18), and tie rod (17).

Removal

1. Park machine on a level surface, stop engine, set

parking brake, and remove key from the ignition.

WARNING

Before jacking up the machine, review and follow

Jacking Instructions in Chapter 1 – Safety.

2. Chock wheels not being jacked up. Jack front wheel

off the ground, and place blocks beneath the frame.

3. Remove tire and front wheel as follows:

A. Remove plastic dust cap carefully from the wheel

to prevent damage to the cap.

B. Remove cap screw and washers securing the

wheel to the spindle. Slide tire and wheel assembly

from the spindle shaft.

4. Remove spindle as follows:

A. Remove jam nuts securing tie rod ball joint to the

spindle. Separate ball joint from the spindle. Remove

tie rod from Pitman arm if necessary.

B. Remove lock nut and cap screw (king pin) secur-

ing the spindle to the A–arm. Separate spindle from

the A–arm.

Loading...

Loading...