ServicingtheBattery

ServiceInterval:Every25hours—Checktheelectrolyte

level(orevery30daysifthemachineis

instorage).

Every50hours—Checktheconditionofthebattery.

Important:Beforeweldingonthemachine,disconnect

thenegativecablefromthebatterytopreventdamageto

theelectricalsystem.

Note:Keeptheterminalsandtheentirebatterycaseclean

becauseadirtybatterydischargesslowly.Tocleanthebattery,

washtheentirecasewithasolutionofbakingsodaandwater.

Rinsewithclearwater.Coatthebatterypostsandcable

connectorswithGrafo112X(skin-over)grease(ToroPart

No.505-47)orpetroleumjellytopreventcorrosion.

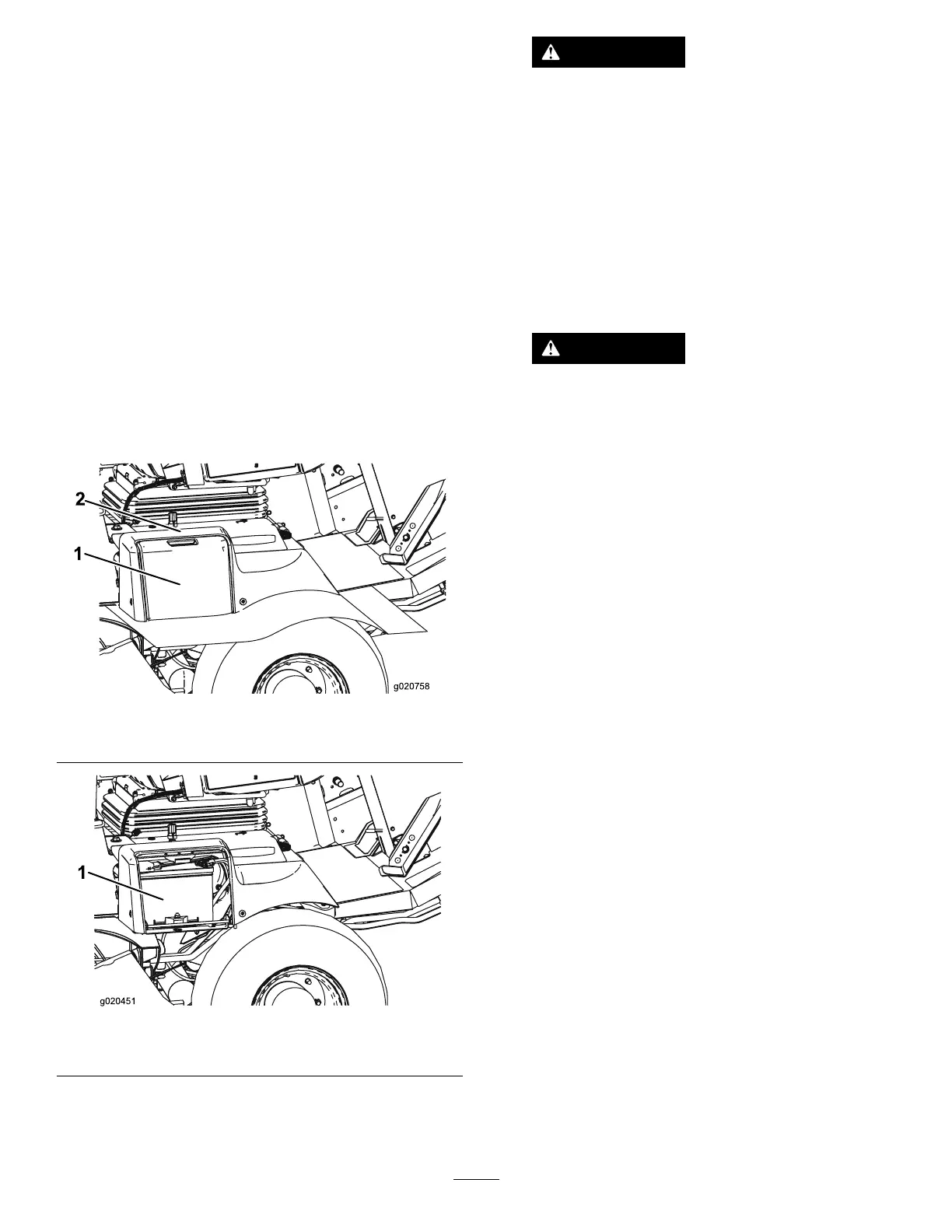

1.Openthebatterycoveronthesideoftheshroud

(Figure52).

Note:Pressdownontheatsurfaceabovethebattery

covertoeasetheremovalofthecover(Figure52).

Figure52

1.Batterycover2.Pressdownhere.

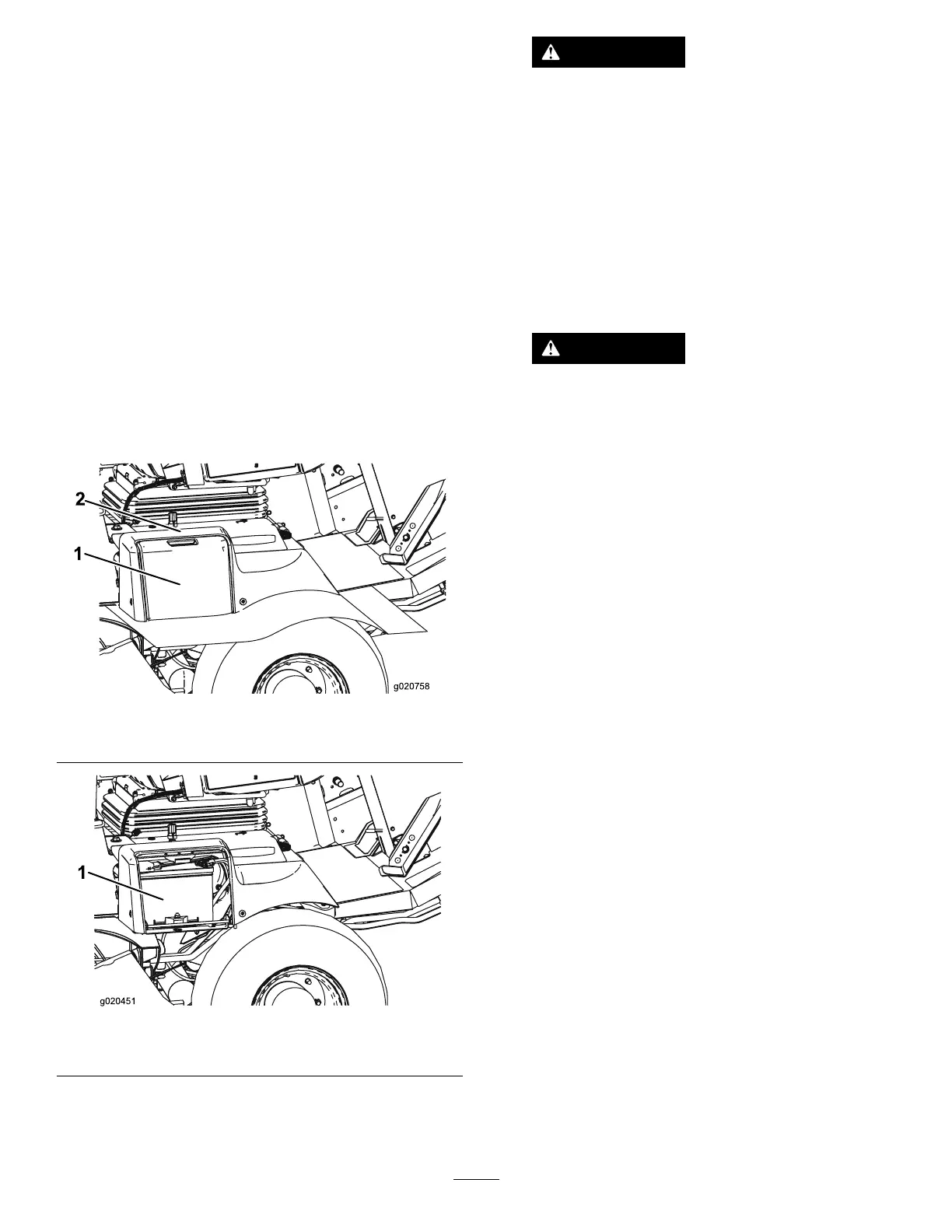

Figure53

1.Battery

2.Removetherubberbootfromthepositiveterminal

andinspectthebattery.

WARNING

Batteryterminalsormetaltoolscouldshort

againstmetalcomponentscausingsparks.

Sparkscancausethebatterygassesto

explode,resultinginpersonalinjury.

•Whenremovingorinstallingthebattery,

donotallowthebatteryterminalstotouch

anymetalpartsofthemachine.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsof

themachine.

WARNING

Incorrectbatterycableroutingcoulddamage

themachineandcablescausingsparks.

Sparkscancausethebatterygassesto

explode,resultinginpersonalinjury.

•Always

disconnect

thenegative(black)

batterycablebeforedisconnectingthe

positive(red)cable.

•Always

connect

thepositive(red)battery

cablebeforeconnectingthenegative

(black)cable.

3.CoatbothbatteryconnectionswithGrafo112X

(skin-over)grease(ToroPartNo.505-47),petroleum

jelly,orlightgreasetopreventcorrosion.

4.Slidetherubberbootoverthepositiveterminal.

5.Closethebatterycover.

44

Loading...

Loading...