AdjustingtheWingMower-DeckPitch

ServiceInterval:Every800hours

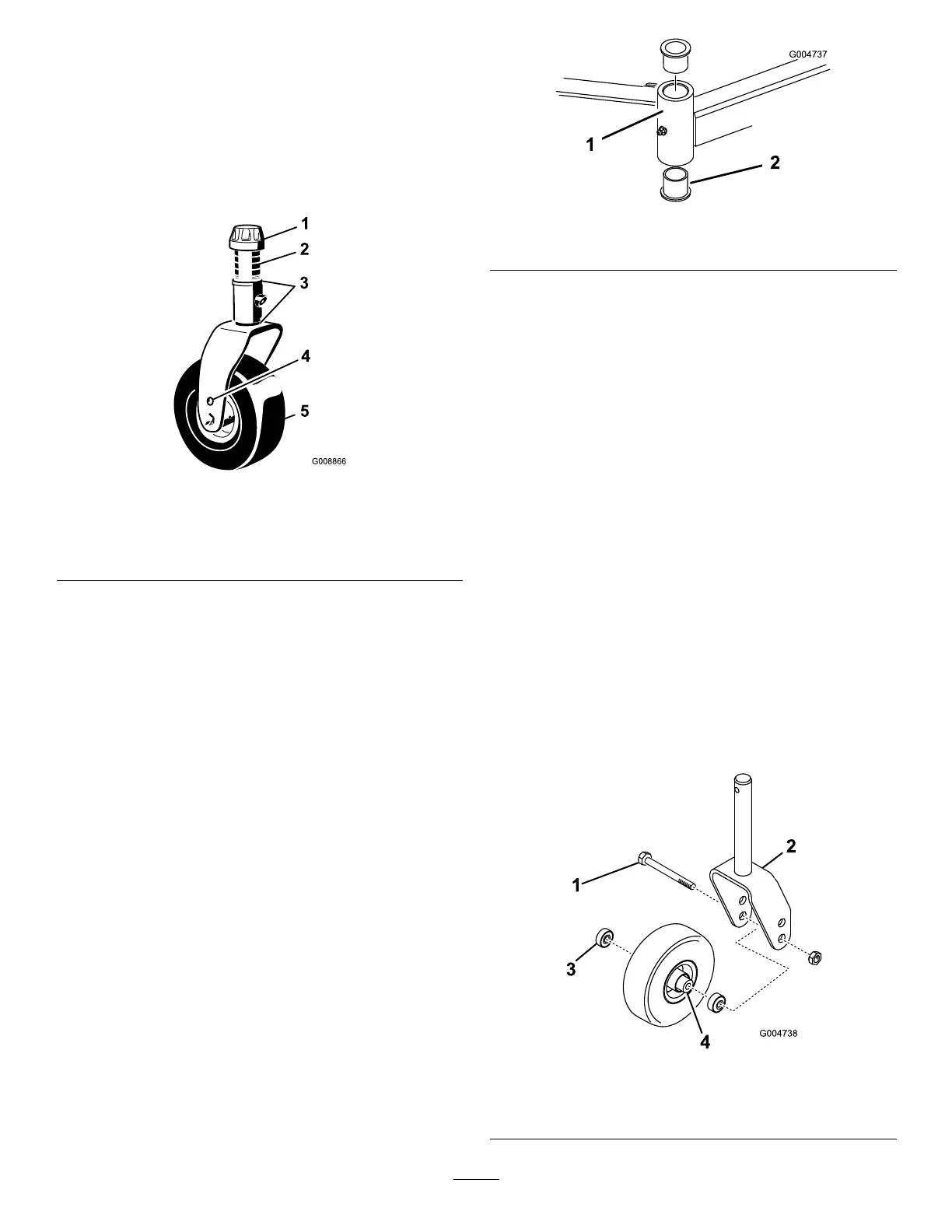

1.Removethetensioningcapfromthespindleshaftand

slidethespindleoutofthecasterarm(Figure78).

Note:Positiontheshims,asrequired,toraiseorlower

thecasterwheeluntilthemowerdeckhasthecorrect

pitch.

Figure78

1.Tensioningcap4.Axle-mountingholes

2.Spacers5.Casterwheel

3.Shims

2.Installthetensioningcap.

ServicingtheCaster-Arm

Bushings

Thecasterarmshavebushingspressedintothetopand

bottomofthetubeandaftermanyhoursofoperation,the

bushingsdevelopwear.Tocheckthebushings,movethe

casterforkbackandforthandfromsidetoside.Ifthecaster

spindleislooseinsidethebushings,thebushingsareworn

andmustbereplaced.

1.Raisethemowerdecksothewheelsareofftheoor

andblockthemowerdecksoitcannotfall.

2.Removethetensioningcap,spacer(s),andthrust

washerfromthetopofthecasterspindle.

3.Pullthecasterspindleoutofthemountingtube.

Note:Keepthethrustwasherandspacer(s)onthe

bottomofthespindle.

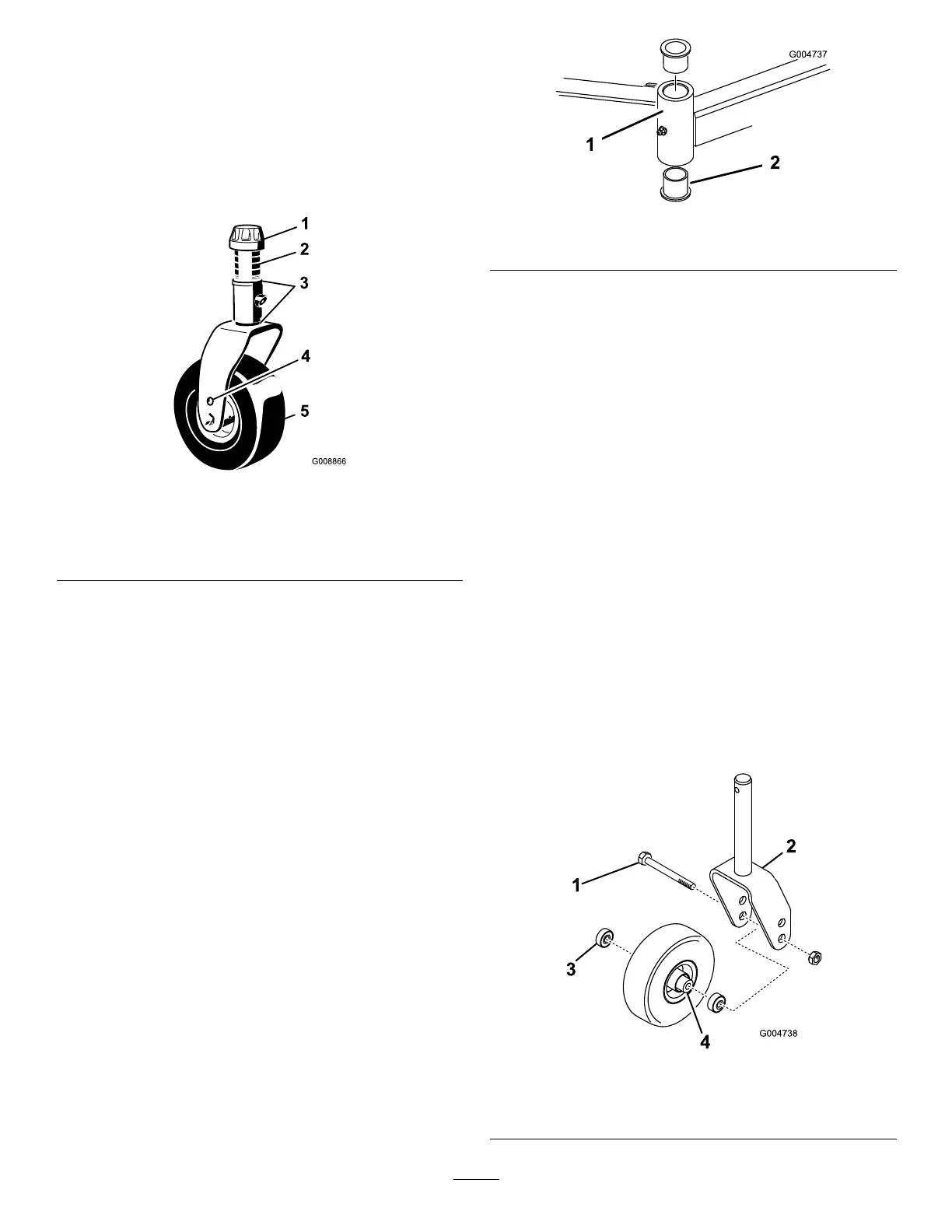

4.Insertapinpunchintothetoporbottomofthe

mountingtubeanddrivethebushingoutofthetube

(Figure79).

Note:Alsodrivetheotherbushingoutofthetube.

Cleantheinsideofthetubestoremovedirt.

Figure79

1.Caster-armtube

2.Bushings

5.Applygreasetotheinsideandoutsideofthenew

bushings.

6.Usingahammerandatplate,drivethebushingsinto

themountingtube.

7.Inspectthecasterspindleforwearandreplaceitifit

isdamaged.

8.Pushthecasterspindlethroughthebushingsand

mountingtube.

9.Slidethethrustwasherandspacer(s)ontothespindle

andinstallthetensioningcaponthecasterspindleto

retainallpartsinplace.

ServicingtheCasterWheels

andBearings

ServiceInterval:Every800hours

1.Removethelocknutfromtheboltholdingthe

caster-wheelassemblybetweenthecasterfork(Figure

80)orthecaster-pivotarm(Figure81).

Note:Graspthecasterwheelandslidetheboltout

oftheforkorpivotarm.

Figure80

1.Casterbolt

3.Bearing

2.Casterfork

4.Bearingspacer

56

Loading...

Loading...