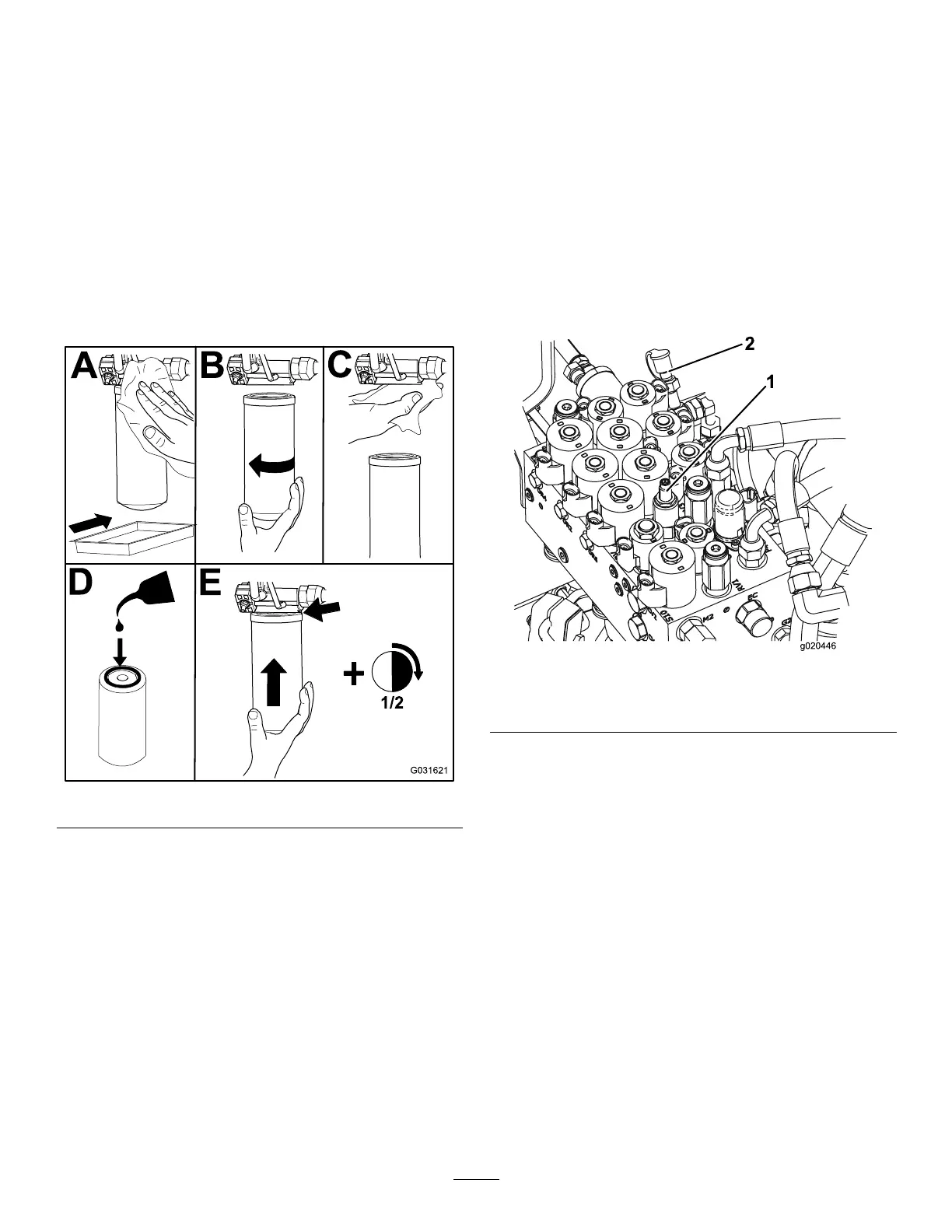

ReplacingtheHydraulicFilters

ServiceInterval:Aftertherst200hours

Every800hours

UseTororeplacementltersPartNo.94-2621fortherear

(mowerdeck)ofthemachineandPartNo.75-1310forthe

front(charge)ofthemachine.

Important:Useofanyotherltermayvoidthewarranty

onsomecomponents.

1.Positionthemachineonalevelsurface,lowerthe

mowerdecks,shutofftheengine,engagetheparking

brakes,andremovetheignitionkey.

2.Replacethehydrauliclters(Figure74).

Figure74

3.Starttheengineandletitrunforabout2minutesto

purgeairfromthesystemandshutofftheengineand

checkforleaks.

CheckingtheHydraulicLines

andHoses

ServiceInterval:Every2years

Inspectthehydrauliclinesandhosesdailyforleaks,kinked

lines,loosemountingsupports,wear,loosettings,weather

deterioration,andchemicaldeterioration.Makeallnecessary

repairsbeforeoperatingthemachine.

AdjustingtheCounterbalance

Pressure

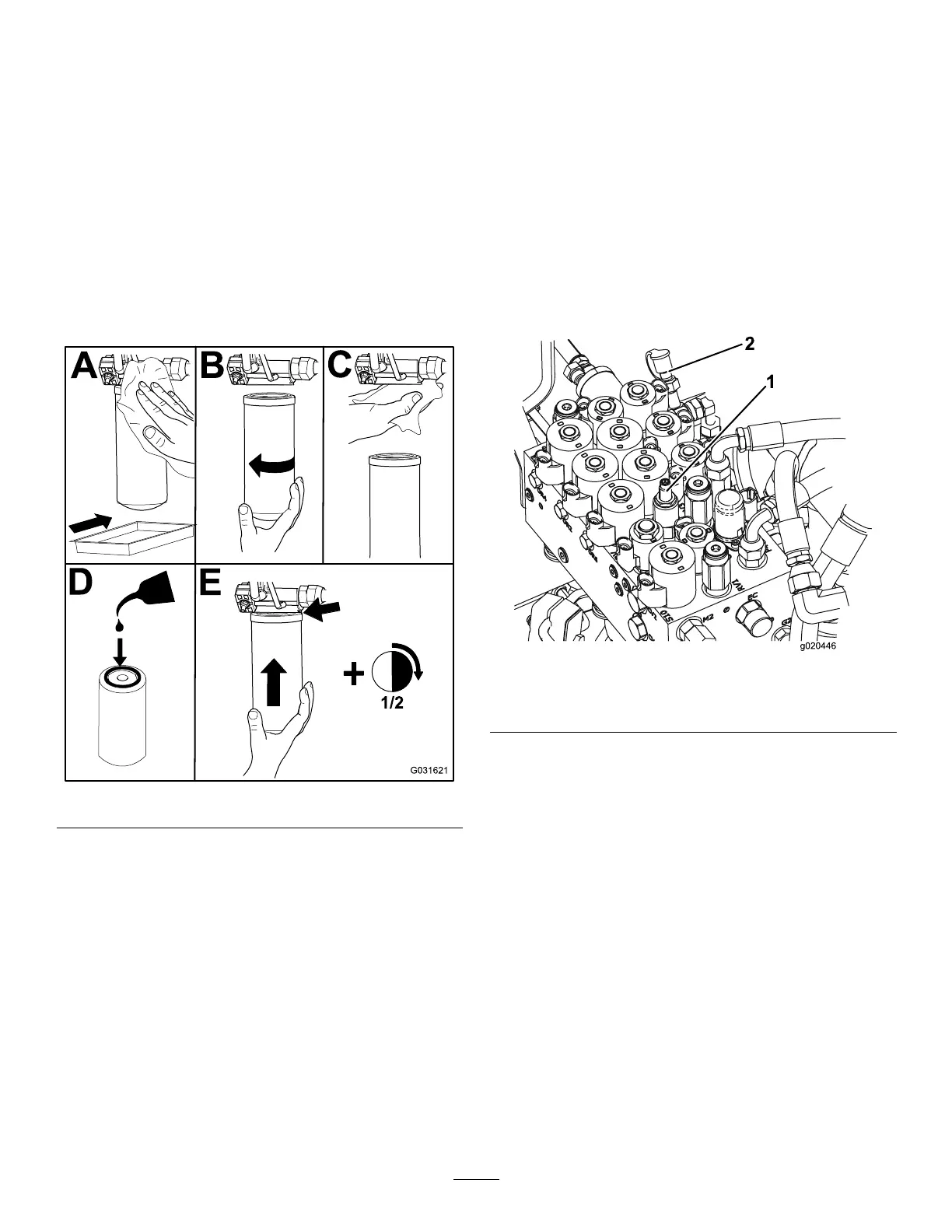

Thecounterbalancetestportisusedtotestthepressurein

thecounterbalancecircuit(Figure75).Therecommended

counterbalancepressureis2,241kPa(325psi).Toadjust

thecounterbalancepressure,loosenthelocknut,rotatethe

adjustingscrew(Figure75)clockwisetoincreasethepressure,

orcounterclockwisetodecreasethepressureandtightenthe

locknut.Theenginemustberunning,thedeckloweredand

intheoatpositiontocheckthepressure.

Note:Thecasterwheelsofall3mowerdecksshouldremain

onthegroundwhenadjustingthecounterbalanceandwith

counterbalanceapplied.

Figure75

1.Counterbalance-adjusting

screw

2.Counterbalance-testport

54

Loading...

Loading...