UnlatchingtheSeat

Toaccessthehydraulicandothersystemsunderthe

seat,unlatchtheseatandswingitforward.

1.Usetheseat-position-adjustmentlevertoslide

theseatallthewayforward.

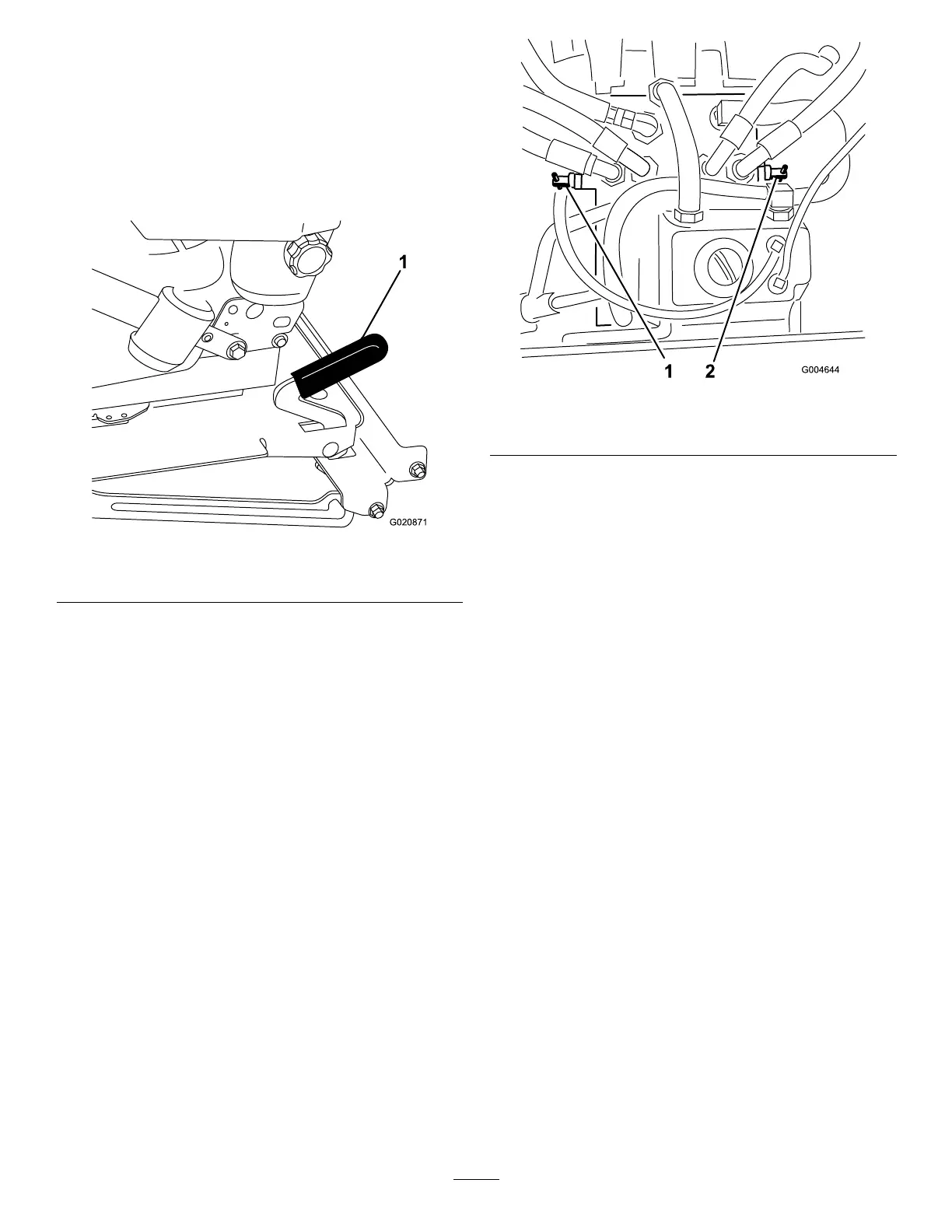

2.Pulltheseatlatchforwardandliftituptounlatch

theseat(Figure56).

g020871

Figure56

1.Seatlatch

PushingtheMachineby

Hand

Important:Nevertowthemachinebecause

hydraulicdamagemayoccur.

PushingtheMachine

1.Disengagethepowertake-off(PTO)andturn

theignitionkeytooff.Movetheleverstothe

NEUTRAL-LOCKEDpositionandapplytheparking

brake.Removethekey.

2.Lifttheseat.

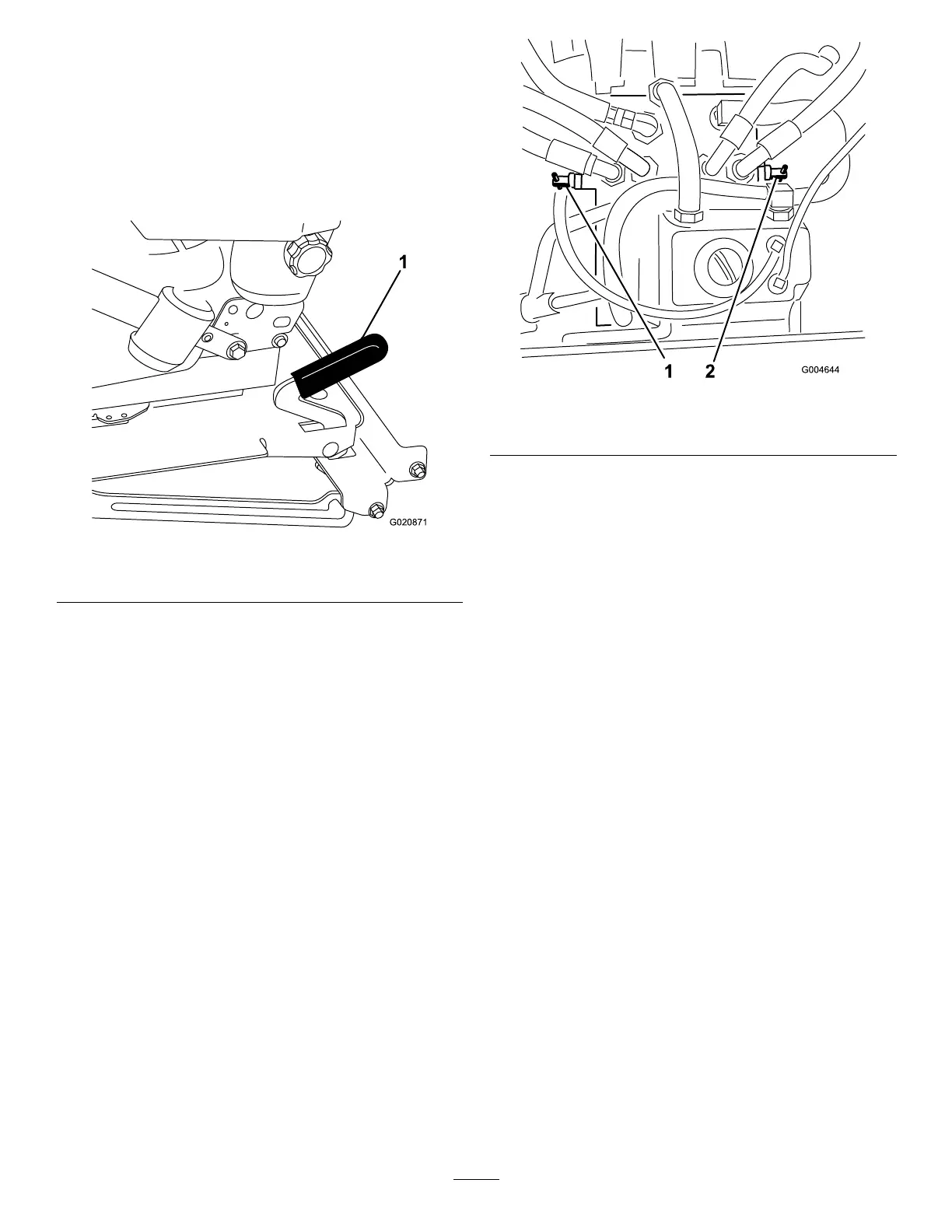

3.Rotateeachbypassvalvecounterclockwise

1turn(Figure57).

Note:Thisallowshydraulicuidtobypassthe

pump,enablingthewheelstoturn.

Important:Donotrotatethebypassvalves

morethan1turn.Thispreventsvalvesfrom

comingoutofthebodyandcausinguidto

runout.

g004644

Figure57

1.Rightbypassvalve

2.Leftbypassvalve

4.Disengagetheparkingbrakebeforepushing.

ChangingtoMachineOperation

Rotateeachbypassvalveclockwise1turnandhand

tightenthem(torqueofapproximately8N-m(71in-lb).

Note:Donotovertightenthebypassvalves.

Themachinedoesnotdriveunlessthebypassvalves

areturnedinward.

LoadingtheMachine

Useextremecautionwhenloadingunitsontrailers

ortrucks.Use1full-widthrampthatiswideenough

toextendbeyondthereartiresinsteadofindividual

rampsforeachsideoftheunit(Figure58).Thelower

rearsectionoftheframeofthemachineextendsback

betweentherearwheelsandservesasastopfor

tippingbackward.Usingafull-widthrampprovides

asurfacefortheframememberstocontactifthe

unitstartstotipbackward.Ifitisnotpossibletouse

1full-widthramp,useenoughindividualrampsto

simulateafull-width,continuousramp.

Therampshouldbelongenoughsothattheangles

donotexceed15degrees(Figure58).Asteeper

anglemaycausemowercomponentstogetcaughtas

theunitmovesfromramptotrailerortruck.Steeper

anglesmayalsocausetheunittotipbackward.If

loadingonornearaslope,positionthetrailerortruck

soitisonthedownsideoftheslopeandtheramp

extendsuptheslope.Thisminimizestherampangle.

Thetrailerortruckshouldbeaslevelaspossible.

43

Loading...

Loading...