EngineMaintenance

CheckingtheAirCleaner

1.Checktheair-cleanerbodyfordamage,which

couldpossiblycauseanairleak.Replacea

damagedaircleanerbody.

2.Checkthewholecleanairintakesystemfor

leaks,damage,orloosehoseclamps.

3.Servicetheair-cleanerlterwhentheair-cleaner

indicator(Figure64)showsredorevery400

hours(morefrequentlyinextremelydustyor

dirtyconditions).

Important:Donotoverservicetheairlter.

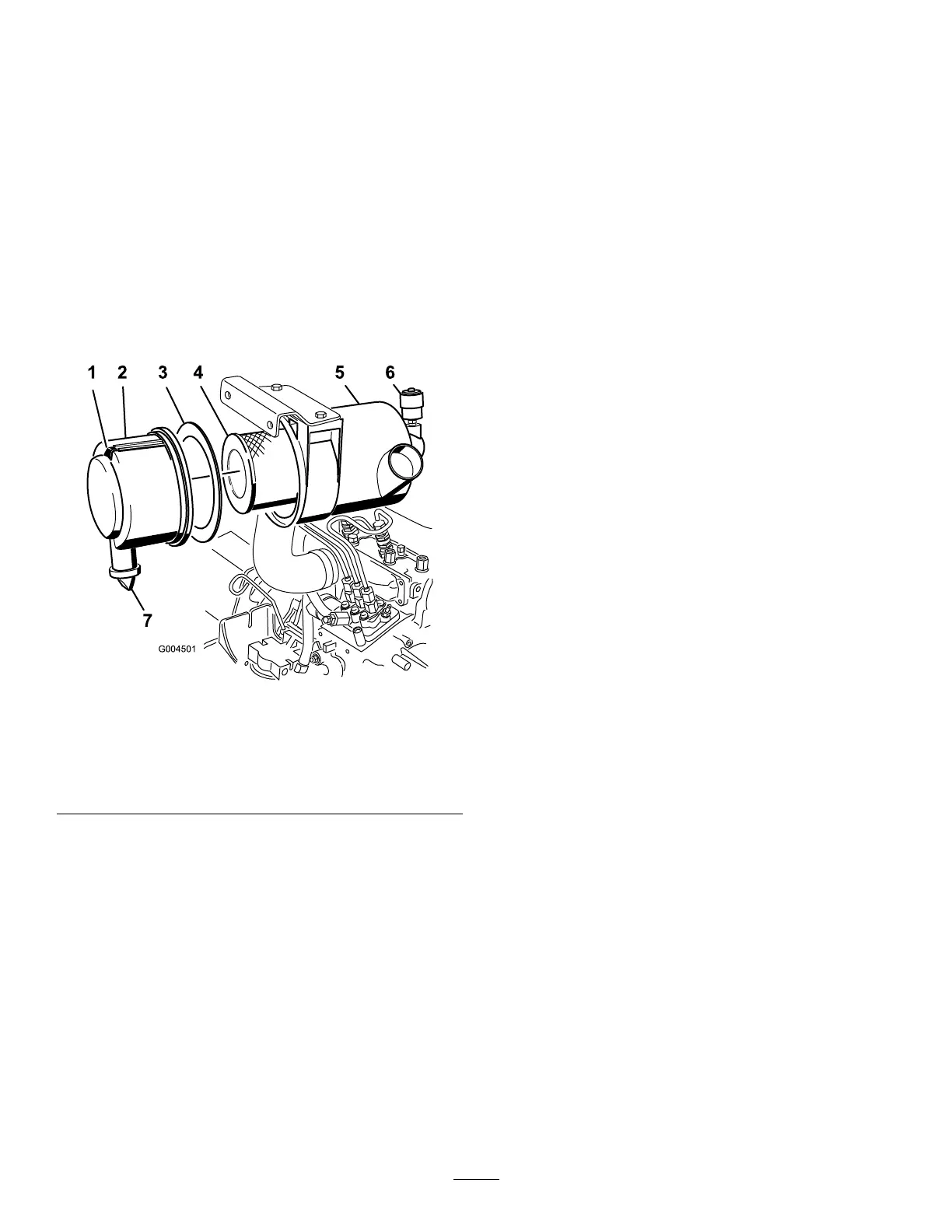

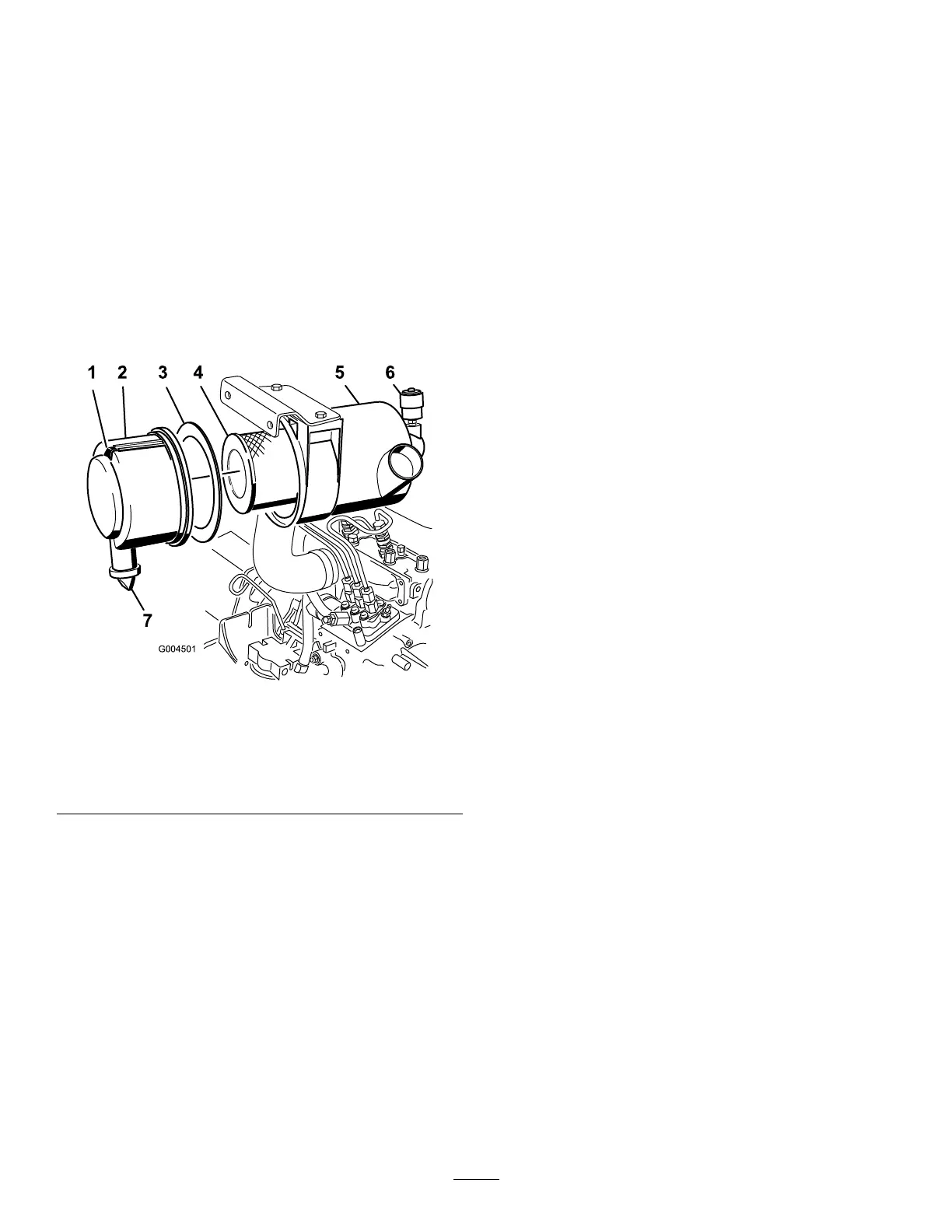

g004501

Figure64

1.Air-cleanercover5.Air-cleanerbody

2.Air-cleanerlatch6.Air-cleanerindicator

3.Gasket

7.Rubberoutletvalve

4.Filter

4.Besurethatthecoverisseatedcorrectlyand

sealswiththeair-cleanerbody.

ServicingtheAirCleaner

ServiceInterval:Every400hours

1.Pullthelatchoutwardandrotatetheair-cleaner

covercounter-clockwise(Figure64).

2.Removethecoverfromtheair-cleanerbody

(Figure64).

3.Beforeremovingthelter,uselowpressureair

(40psi,cleananddry)tohelpremovelarge

accumulationsofdebrispackedbetweenoutside

ofprimarylterandthecanister.

Note:Thiscleaningprocesspreventsdebris

frommigratingintotheintakewhenyouremove

theprimarylter.

Important:Avoidusinghigh-pressureair

whichcouldforcedirtthroughthelterinto

theintaketract.

4.Removeandreplacetheprimarylter(Figure

64).

Important:Donotcleantheusedelementto

avoiddamagetotheltermedia.

5.Inspectthenewlterforshippingdamage,

checkingthesealingendofthelterandthe

body.

Important:Donotuseadamagedelement.

6.Ensurethatthefoamgasketisinplaceinthe

coverandthatitisnottornordamaged(Figure

64).

Note:Ifitisdamaged,replaceit.

7.Insertthenewlterbyapplyingpressuretothe

outerrimoftheelementtoseatitinthecanister.

Important:Donotapplypressuretothe

exiblecenterofthelter.

8.Cleanthedirt-ejectionport(locatedinthe

removablecover)asfollows:

A.Removetherubberoutletvalvefromthe

cover(Figure64).

B.Cleanthecavity.

C.Replacetheoutletvalve.

9.Installthecoverorientingtherubberoutletvalve

inadownwardposition—betweenapproximately

5:00to7:00whenviewedfromtheend.

10.Resettheindicator(Figure64)ifitisshowing

red.

52

Loading...

Loading...