BeltMaintenance

CheckingtheAlternator

Belt

ServiceInterval:Every100hours

Propertensionallows10mm(3/8inch)deection

whenaforceof44N(10lb)isappliedonthebelt

midwaybetweenthepulleys.

Ifthedeectionisnot10mm(3/8inch),completethe

followingprocedure:

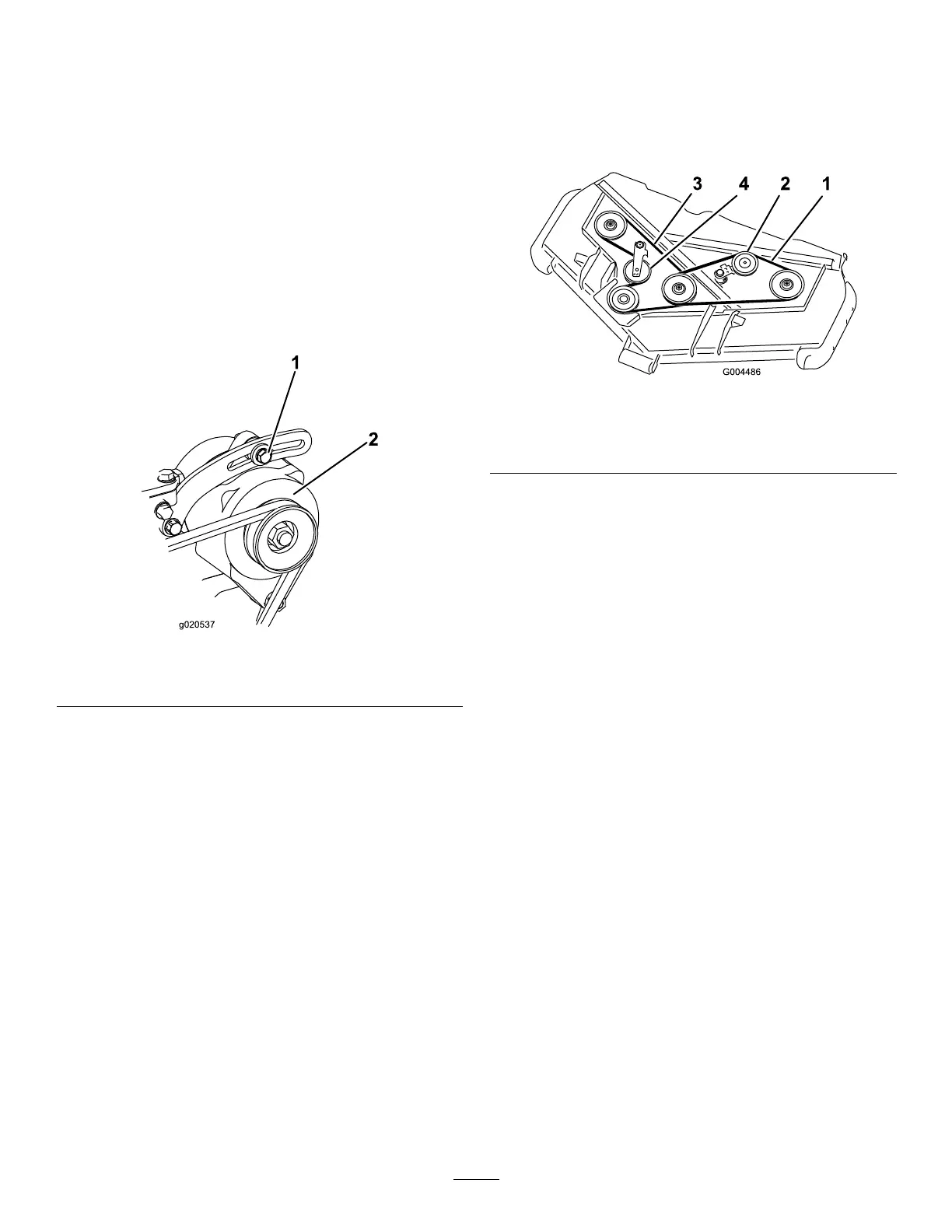

1.Loosenthealternatormountingbolts(Figure

78).

g020537

Figure78

1.Mountingbolt2.Alternator

2.Increaseordecreasethealternator-belttension

andtightenthebolts.

3.Checkthedeectionofthebeltagaintoensure

thatthetensioniscorrect.

ReplacingtheBladeDrive

Belts

ServiceInterval:Every50hours

Thebladedrivebelts,tensionedbythespring-loaded

idlerpulleys,areverydurable.However,aftermany

hoursofuse,thebeltswillshowsignsofwear.Signs

ofawornbeltare:squealingwhenbeltisrotating,

bladesslippingwhencuttinggrass,frayededges,

burnmarksandcracks.Replacethebeltsifanyof

theseconditionsareevident.

1.Lowerthecuttingunittothe2.54cm(1inch)

height-of-cutsetting,movethethrottlelever

totheSLOWposition,stoptheengine,setthe

parkingbrake,andremovetheignitionkey.

2.Removethebeltcoversfromthetopofthe

cuttingunitandsetthecoversaside.

3.Usingabreakerbarorsimilartool,movethe

idlerpulleyforthetopbeltawayfromthetop

drivebelttoreleasethebelttensionandslipthe

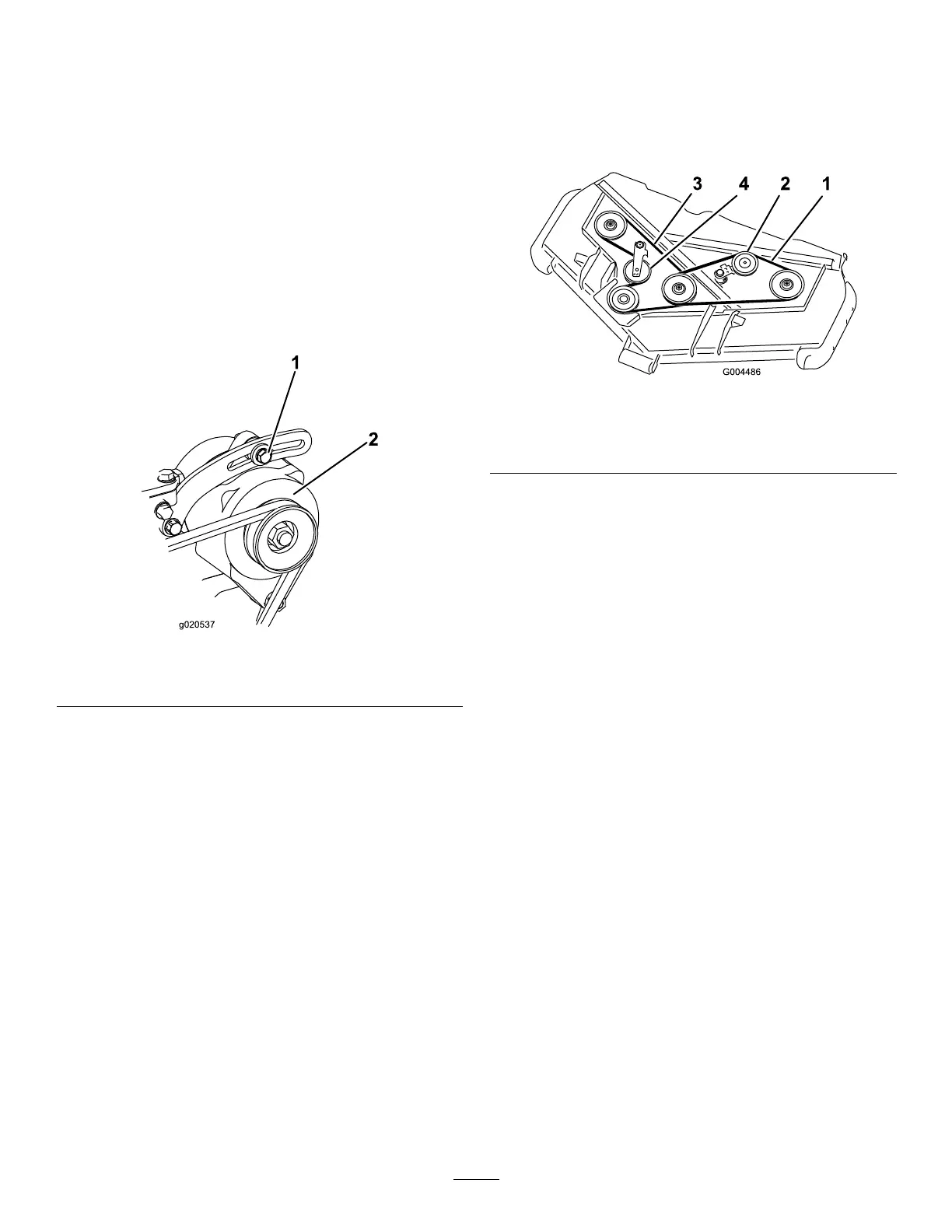

beltoffthepulleys(Figure79).

g004486

Figure79

1.Topbelt3.Bottombelt

2.Topidlerpulley4.Bottomidlerpulley

4.Usingabreakerbarorsimilartool,movethe

idlerpulleyforthebottombeltawayfromthe

bottomdrivebelttoreleasethebelttension

andallowthebelttobeslippedoffthepulleys

(Figure79).

5.Routeanewbeltaroundthegearboxpulley,

bottomspindlepulleys,andidler-pulley

assemblyasshowninFigure79.

6.Routeanewbeltaroundthetopspindlepulleys

andidler-pulleyassemblyasshowninFigure79.

7.Installthebeltcovers.

61

Loading...

Loading...