DriveSystem

Maintenance

CheckingtheTirePressure

ServiceInterval:Every50hours

Maintaintheairpressureinthefrontandreartires.

Thecorrectairpressureis124kPa(18psi)inthe

reartiresand172kPa(25psi)inthecasterwheels.

Uneventirepressurecancauseanunevencut.

Checkthetireswhentheyarecoldtogetthemost

accuratepressurereading.

g001055

Figure73

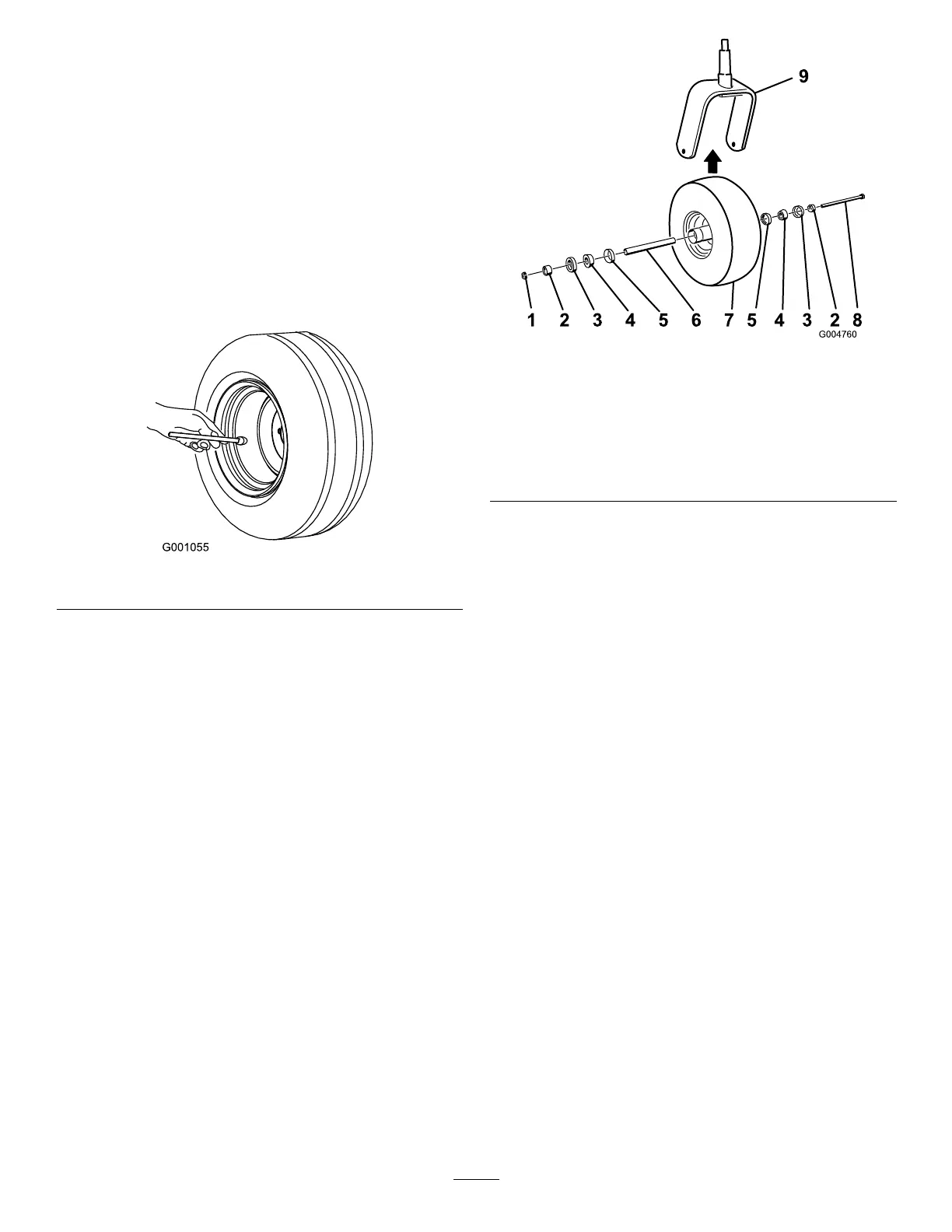

ReplacingtheCaster

WheelsandBearings

1.Obtainanewcasterwheelassembly,cone

bearings,andbearingsealsfromyour

AuthorizedT oroDistributor.

2.Removethelocknutfromtheboltholdingthe

caster-wheelassemblybetweenthecasterfork

(Figure74).

g004760

Figure74

1.Nut

6.Spacer

2.Bearingspacer

7.Casterwheel

3.Outerbearingseal

8.Axlebolt

4.Conebearing9.Casterfork

5.Innerbearingseal

3.Graspthecasterwheel,andslidetheboltout

oftheforkorpivotarm.

4.Discardtheoldcasterwheelandbearings.

5.Assemblethecasterwheelbypushingthecone

bearingsandseals,packedwithgrease,intothe

wheelhub,positionedasshowninFigure74.

6.Slidethespacerintothewheelhubthrough

thebearings,captivatingthespacerinsidethe

wheelhubwith2bearingspacers.

Important:Ensurethattheseallipsarenot

foldedinward.

7.Installthecaster-wheelassemblybetweenthe

castorforkandsecureitinplacewiththebolt

andlocknut.

8.Tightenthenutuntilthewheelnolongerspins

freely,thenbackitoffjustuntilthewheelspins

freely.

9.Attachagreaseguntothegreasetting

onthecasterwheelandllitwithNo.2

general-purpose,lithiumgrease.

58

Loading...

Loading...