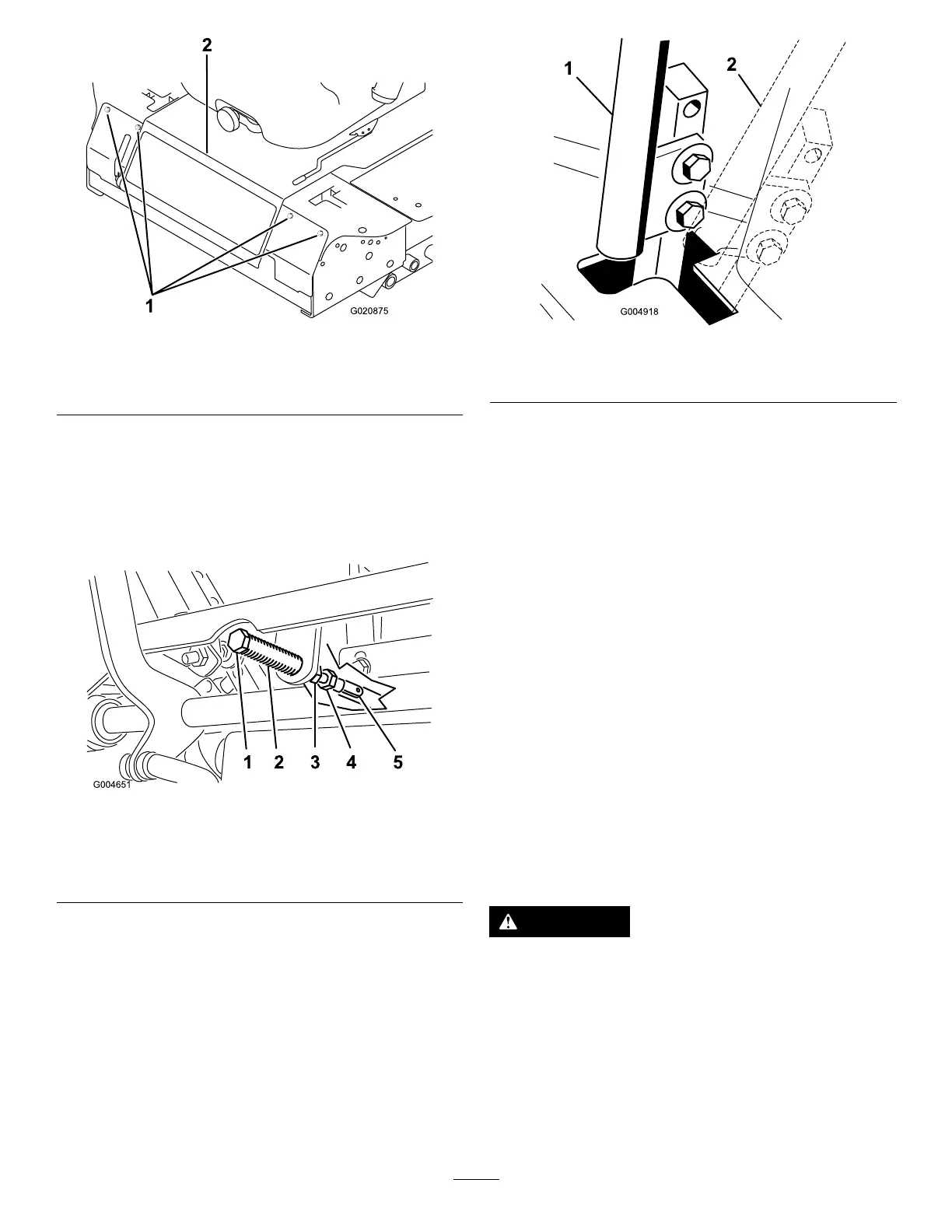

g020875

Figure82

1.Bolts

2.Controlpanel

4.MovethecontrollevertotheNEUTRALposition

butnotlocked(Figure84).

5.Pulltheleverbackuntiltheclevispin(onan

armabovethepivotshaft)contactstheendof

theslot(justbeginningtoputpressureonthe

spring)asshowninFigure83.

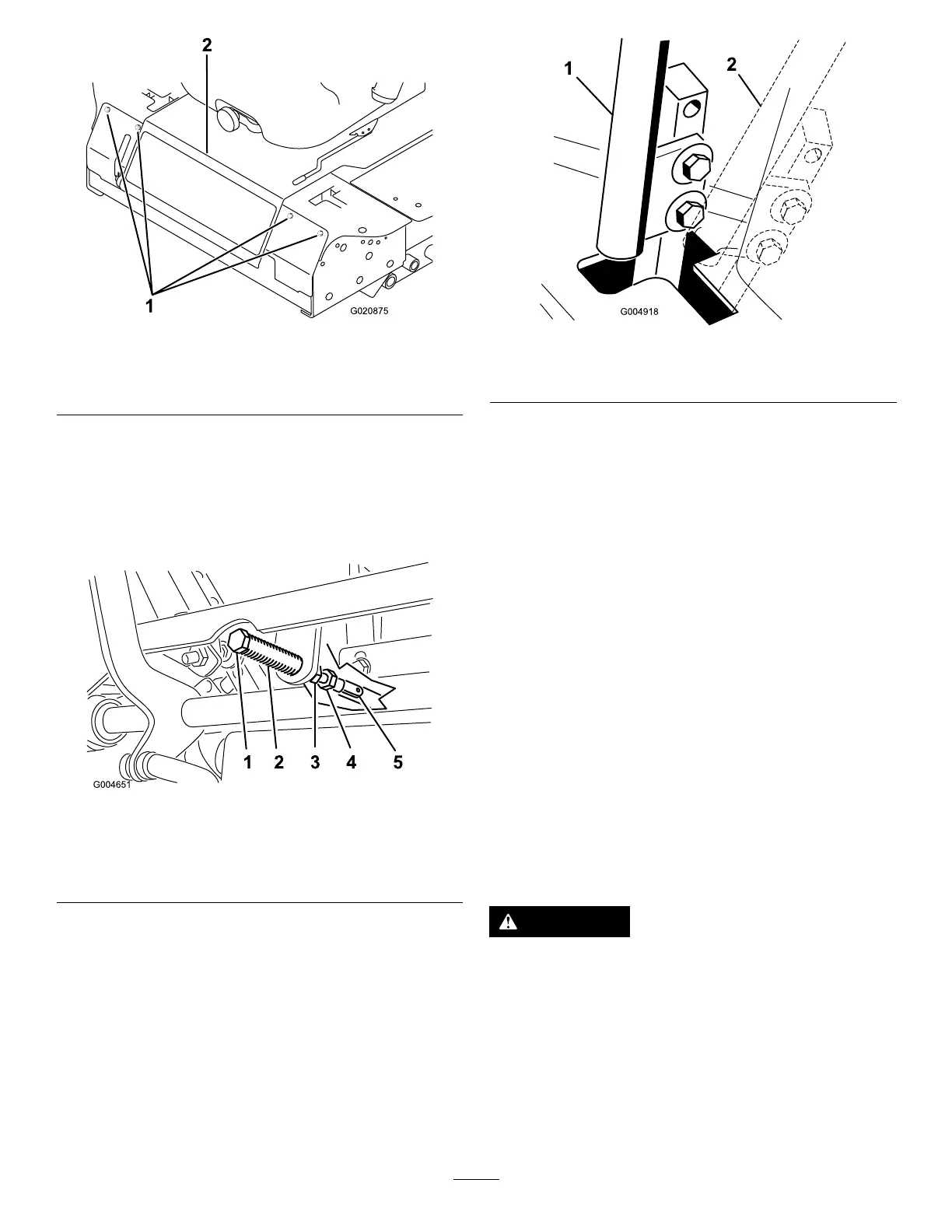

g004651

Figure83

1.Clevispin

4.Adjustmentbolt

2.Slot

5.Yoke

3.Jamnuts

6.Checkwherethecontrolleverisrelativetonotch

inconsole(Figure84).

Note:Thecontrollevershouldbe

centered,allowingittopivotoutwardtothe

NEUTRAL-LOCKEDposition.

g004918

Figure84

1.Neutralposition2.Neutral-lockedposition

7.Ifadjustmentisneeded,loosenthenutandjam

nutagainsttheyoke(Figure83).

8.Applyingslightrearwardpressureonthe

motion-controllever,turntheheadofthe

adjustmentboltintheappropriatedirection

untilthecontrolleveriscenteredinthe

NEUTRAL-LOCKEDposition(Figure83).

Note:Keepingrearwardpressureonthelever

keepsthepinattheendoftheslotandallows

theadjustmentbolttomovethelevertothe

appropriateposition.

9.Tightenthenutandjamnut(Figure83).

10.Repeatsteps4through9fortheothercontrol

lever.

11.Installthefrontpanel.

AdjustingtheTraction

DriveforNeutral

Thisadjustmentmustbemadewithdrivewheels

turning.

DANGER

Mechanicalorhydraulicjacksmayfailto

supportthemachineandcauseaserious

injury.

•Usejackstandswhensupportingthe

machine.

•Donotusehydraulicjacks.

63

Loading...

Loading...