ChangingtheHydraulicFilters

RemovingtheTraction-pedalAssembly

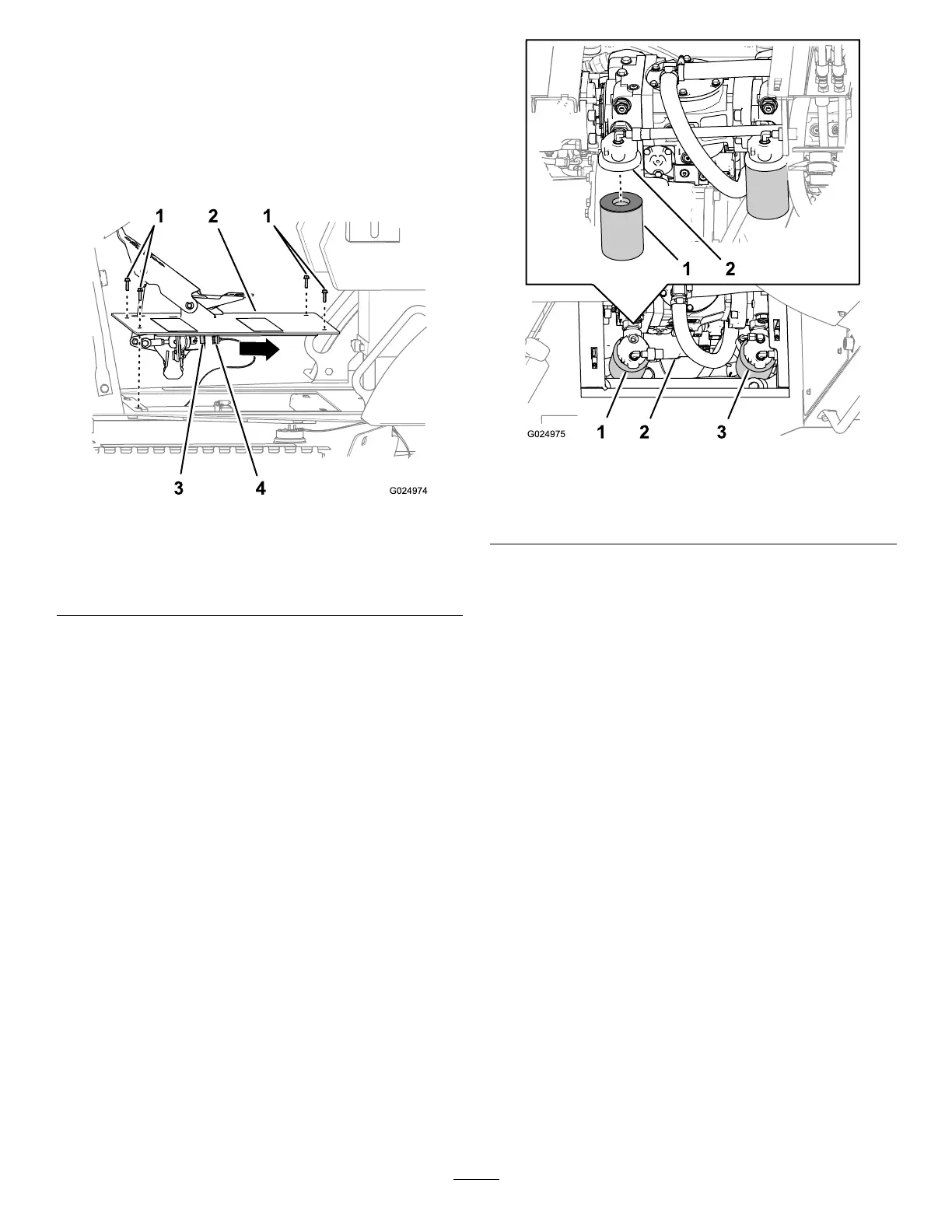

Removethetraction-pedalassemblyasfollows:

1.Removethe4hex-angedheadboltsthatsecurethat

traction-pedalassemblytothechassisofthemachine

(Figure110).

Figure110

1.Hex-angedheadbolts

3.6-pinconnector

(traction-pedalsensor)

2.Traction-pedalassembly4.6-socketconnector

(machineharness)

2.Disconnectthe6-socketconnectorofthemachine

harnessfromthe6-pinconnectorofthetraction-pedal

sensor(Figure110).

3.Removethetraction-pedalassemblyfromthemachine

(Figure110).

ChangingtheHydraulic-chargeFilter

ServiceInterval:Every500hours

Note:Changethehydraulic-returnlterwhenyouchange

thehydraulic-chargelter.

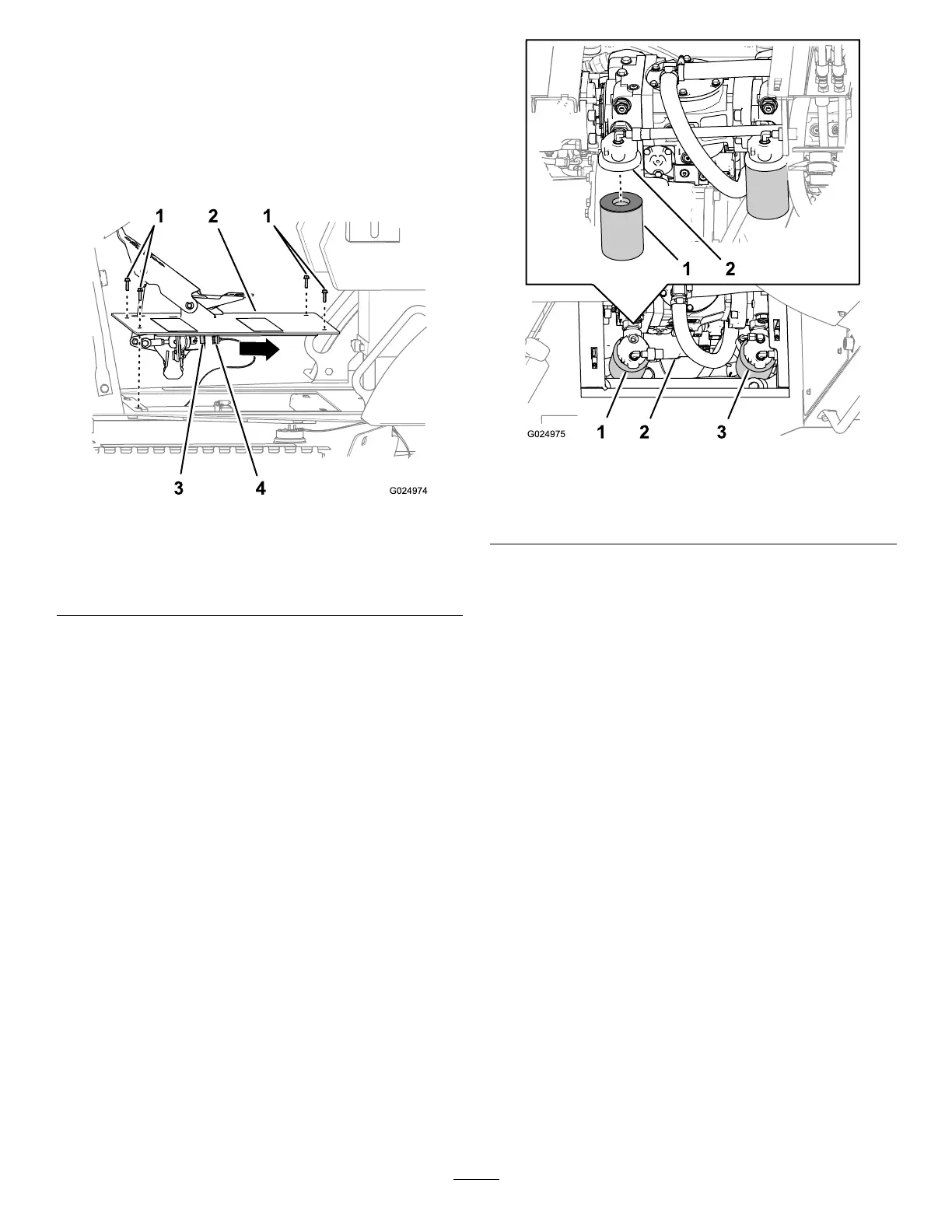

Note:Youcanaccessthehydraulic-chargelterfromunder

therightsideofthemachine,behindthehydraulicreservoir

(Figure111).

1.Removethetraction-pedalassembly;refertoRemoving

theTraction-pedalAssembly(page72).

2.Placeacontainerunderthehydraulic-chargelter

(Figure111).

Figure111

1.Containersuitablefor

hydraulicuid

3.Hydraulic-chargelter

2.Sharpobject

3.Rotatethehydraulic-chargeltercounterclockwiseand

removethelter(Figure111).

Note:Discardthelter.

4.Applyathinlayerofthespeciedhydraulicuidto

theO-ringofthenewlter.

Important:Donotusealterstrapwrenchto

tightenthelter.Astrapwrenchcandentthe

lter,causingittoleak.

5.Fillthenewchargelterwiththespeciedhydraulic

uid,allowthelterelementtosaturatewiththeuid,

andthenpourouttheexcessuid.

6.Installthenewlter.

Note:Useyourhandstotightenthelteranadditional

halfturnaftertheltermakescontactwiththelter

head.

7.Repeatsteps3through6fortheotherchargelter

8.Checkthelevelofthehydraulicuidinthehydraulic

reservoir;refertoCheckingtheHydraulic-FluidLevel

(page26).

9.Starttheengineandletitidlefor1or2minutes.

10.Shutofftheengine,andcheckforleaksaroundthe

lterarea.

11.Checkthelevelofthehydraulicuidinthehydraulic

reservoir,andadduid,ifnecessary;refertoChecking

theHydraulic-FluidLevel(page26).

72

Loading...

Loading...