DriveSystem

Maintenance

AdjustingtheShiftCables

ServiceInterval:Aftertherst10hours

Every200hours

1.MoveshiftlevertotheNeutralposition.

2.Removetheclevispinssecuringtheshiftcablesto

thetransaxleshiftarms(Figure43).

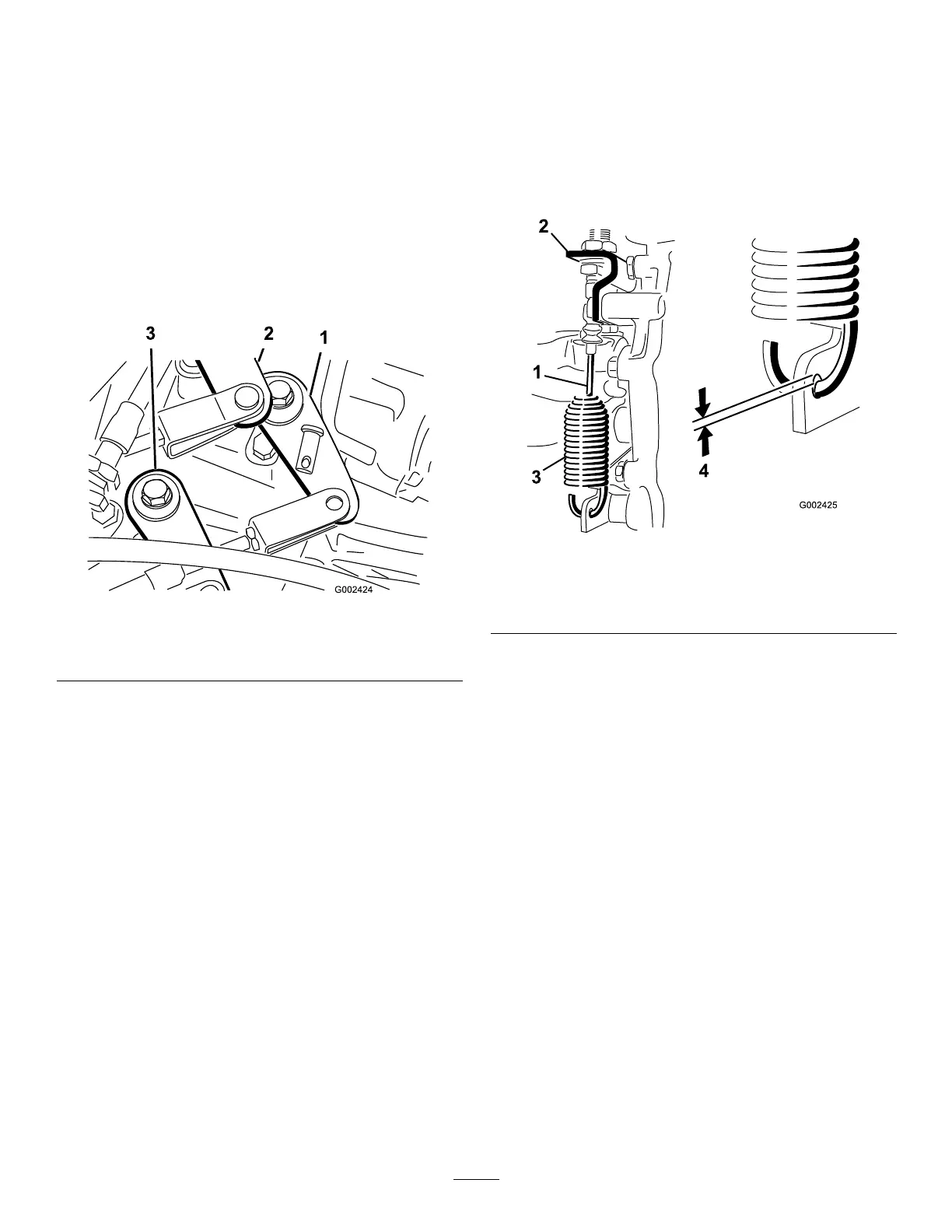

Figure43

1.Shiftarm(1st–Rev.)3.Shiftarm(High–Low)

2.Shiftarm(2nd–3rd)

3.Loosentheclevisjamnutsandadjusteachclevis

socablefreeplayisequalforwardandbackward

relativetotheholeinthetransaxleshiftarm(with

thetransaxleleverfreeplaytakenupinthesame

direction).

4.Installtheclevispinsandtightenthejamnutswhen

nished.

AdjustingtheHigh–LowCable

ServiceInterval:Every200hours

1.RemovetheclevispinsecuringtheHigh–Lowcable

tothetransaxle(Figure43).

2.Loosentheclevisjamnutandadjusttheclevis

sothattheclevisholealignswiththeholeinthe

transaxlebracket.

3.Installtheclevispinandtightenthejamnutwhen

nished.

AdjustingDifferentialLock

Cable

ServiceInterval:Every200hours

1.MovethedifferentiallocklevertotheOffposition.

2.Loosenthejamnutssecuringthedifferentiallock

cabletothebracketonthetransaxle(Figure44).

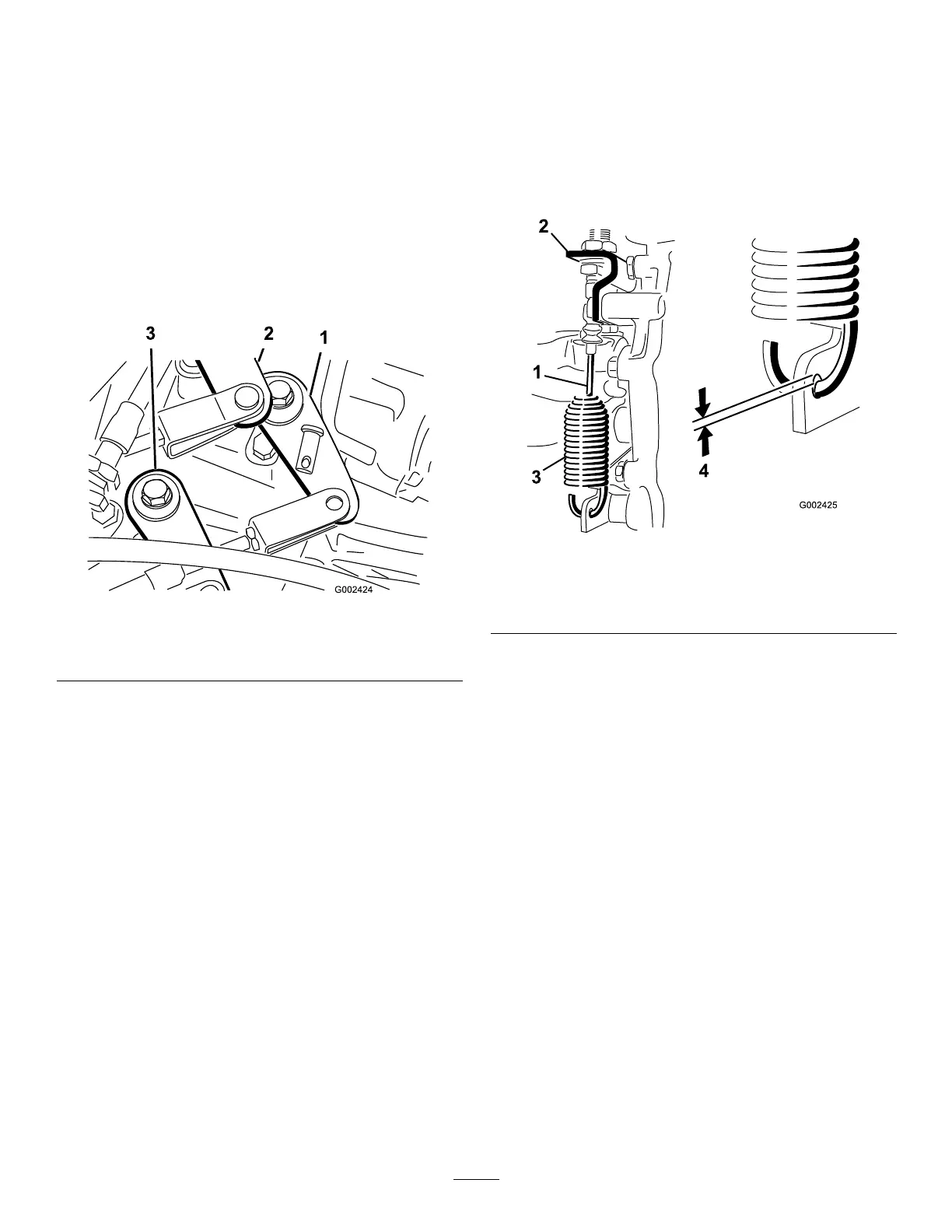

Figure44

1.Differentiallockcable3.Spring

2.Transaxlebracket

4.0.01to0.06inch(0.25to

1.5mm)gap

3.Adjustthejamnutstoobtaina0.01to0.06inch

(0.25to1.5mm)gapbetweenthespringhookand

theO.D.oftheholeinthetransaxlelever.

4.Tightenthejamnutswhennished.

InspectingtheTires

ServiceInterval:Every100hours

Operatingaccidents,suchashittingcurbs,candamagea

tireorrimandalsodisruptwheelalignment,soinspect

tireconditionafteranaccident.

Checkthetirepressurefrequentlytoensureproper

ination.Ifthetiresarenotinatedtothecorrect

pressure,thetireswillwearprematurely.

Figure45isanexampleoftirewearcausedbyunder

ination.

41

Loading...

Loading...