Note:

The lock nut should be calked at a point

completely apart from the threads may damage

the threads of the bevel pinion.

10) When separating the TRB’s from the bevel

pinion,release the calking of the lock nut and

remove the bearings.

2.2 INSPECTION

1) visually check the bearing surfaces of the

bevel pinion and ring gear teeth.

Note:

The bevel pinion and the ring gear should be

replaced as a pair.

2) seriously worn or damaged parts should be

replaced.

2-3.REASSEMBLY

Reassembly the parts in reverse order of

disassembly,following these instructions.

1)Each friction surface should be coated

with grease in advance.

2)The bevel pinion and the ring gear make

a distinct pair after a mesh adjustment

performed at the factory. Consequently,

when reassembling the pair,be sure to

pair parts with a same reference number.

-Tighten the lock nut to the specified

starting torque of the single unit of the

bevel pinion.

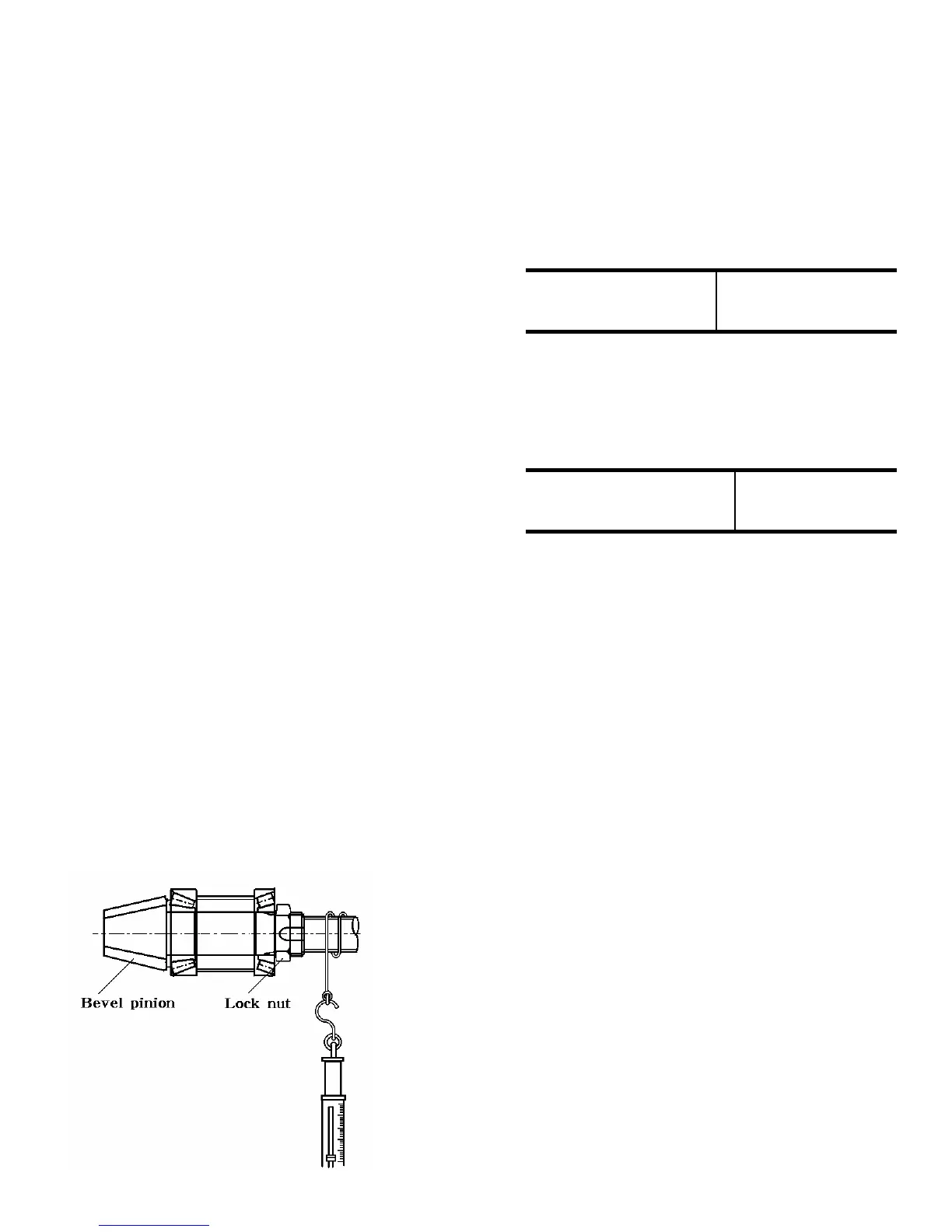

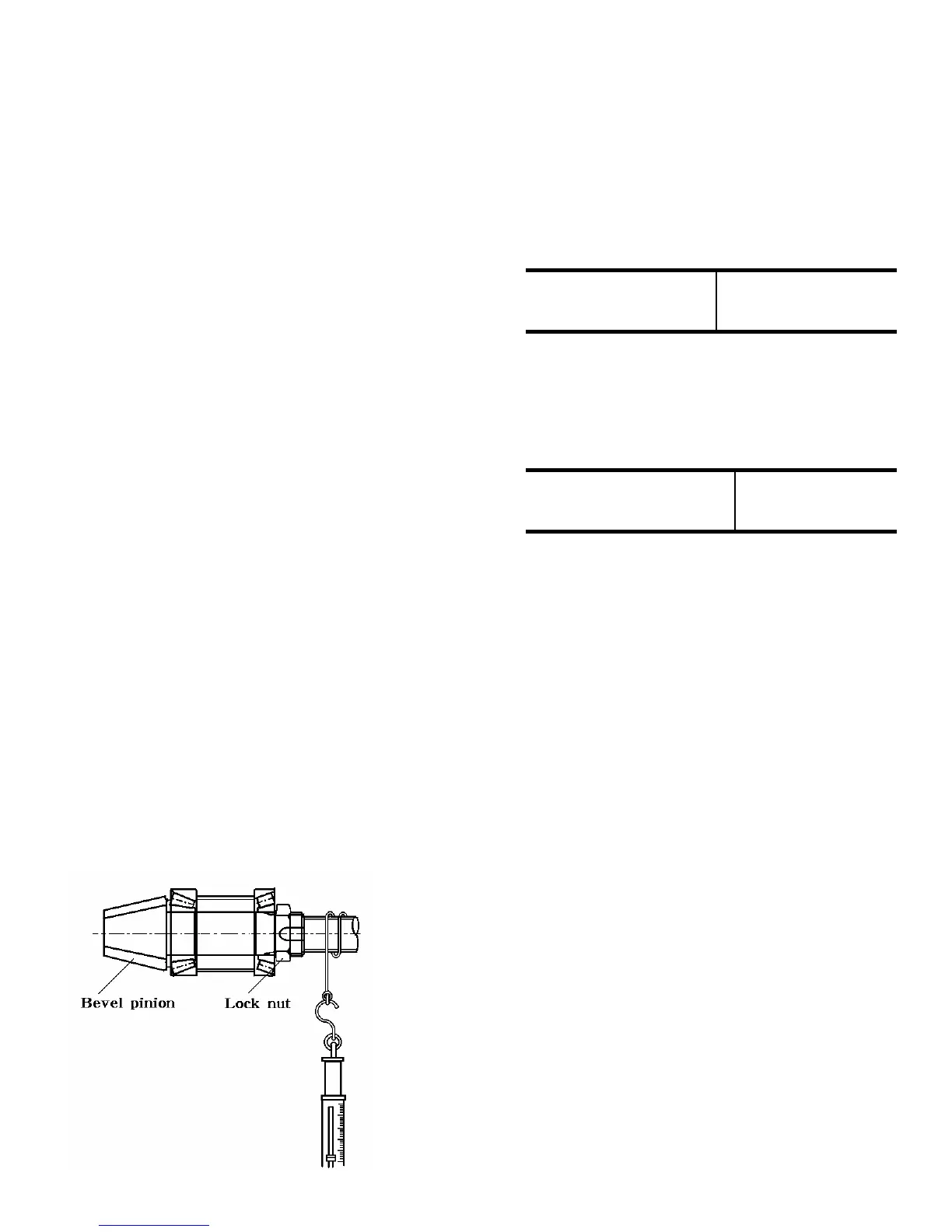

Fig.6-17

Note:

As a general rule,a disassembled lock nut

should be replaced and a new one should

be installed.However,when there is no

alternative but to reuse the disassembled

lock nut assure that it can lock securely.

Note:

Measure the starting torque a manner as

shown in the figure

6 -7 Kgf-cm

(0.43-0.51 ft.lbs)

Specified starting

torque

-When any of the bevel pinion,ring

gear,TRB, collar,etc.has been replaced,

inspect the bevel pinion assembly for

thrust play in the front axle housing.

0 -0.2

(0 -0.008 in)

Specified thrust play

mm(in)

Note:

TRB and collar should be replaced as a pair.

6-8

Loading...

Loading...