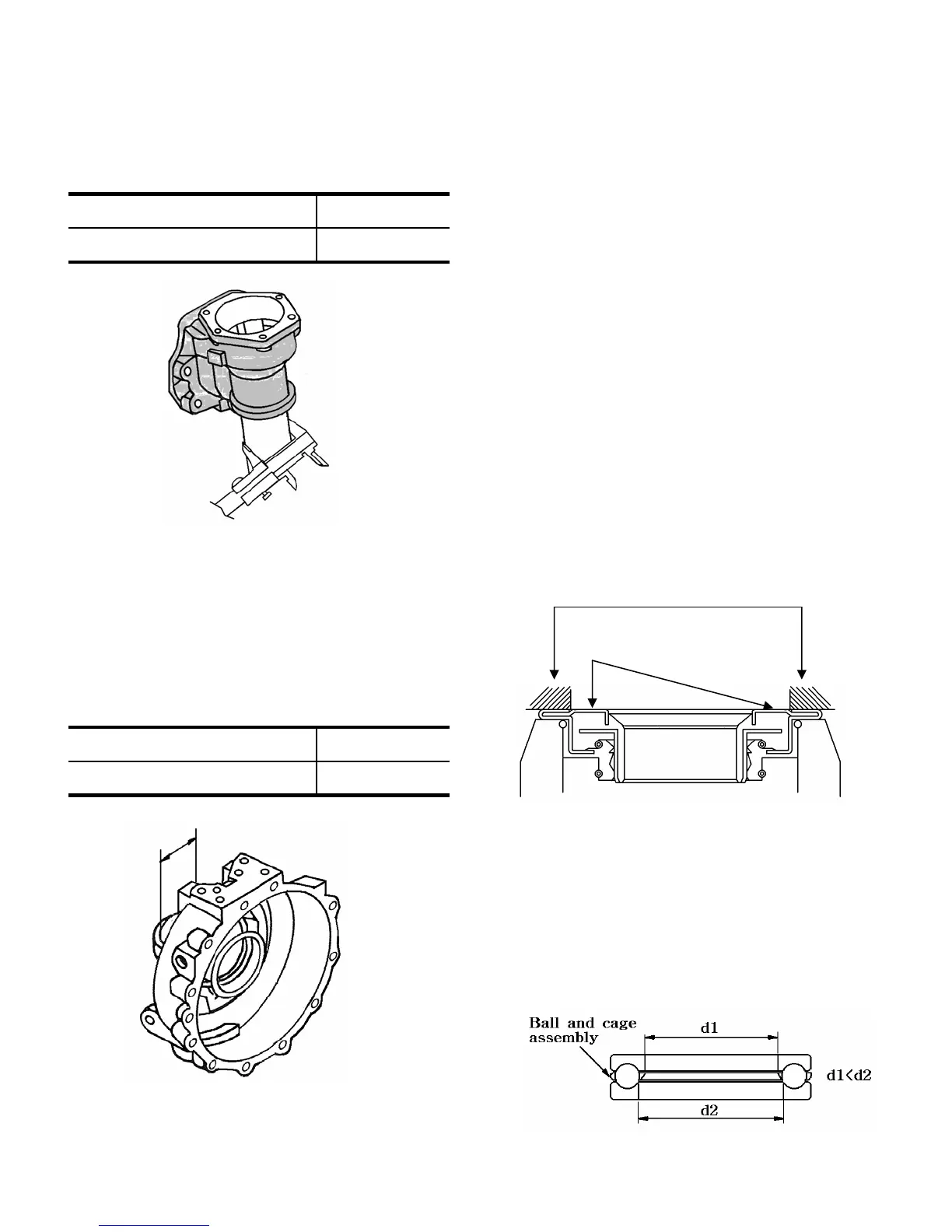

3) Final case A shaft diameter

Measure the diameter of the shaft part which

makes contact with the roll bush with a

micrometer or vernier calipers.When the

measured value is less than the usable

limit,replace the case(Fig.6-27)

Ø54.9 (2.161)Usable limit

Ø55 (2.165)Standard value as assembled

4) Final case B bush bore diameter

Measure the bore diameter of the roll bush

in the final case B with a cylinder gauge or

vernier calipers.When the measured value

exceeds the usable limit,replace the bush.

(Fig. 6-28)

Fig.6-27

Ø55.2 (2.173)Usable limit

Ø55 (2.165)Standard value as assembled

Fig.6-28

5) Inspect other bearings,oil seals,O- rings,

shafts, gears,cases,etc., and replace them

if worn or damaged

3.3 REASSEMBLY

Reassemble the parts in reverse order of

disassembly, following these instructions.

1) Apply an adhesive (THREE BOND TB1215)

to the following parts.

a.Contact surfaces between the final case B

and wheel shaft cover.

b.Contact surfaces between the final case A

and front axle.

2) When driving the seal into the bottom of the

final case A,Apply an adhesive(TB1215) to the

seal in advance.

3) When installing unitized seals on the wheel

shaft cover and the rotating part between the

final cases (A and B),apply force only to the

outer circumference of the seal as shown in

Fig.6-29 to avoid deformation.

Fig.6-29

Apply force only to the shaded parts

Take care not to deform these portions

4)The installed wheel shaft should turn smoothly.

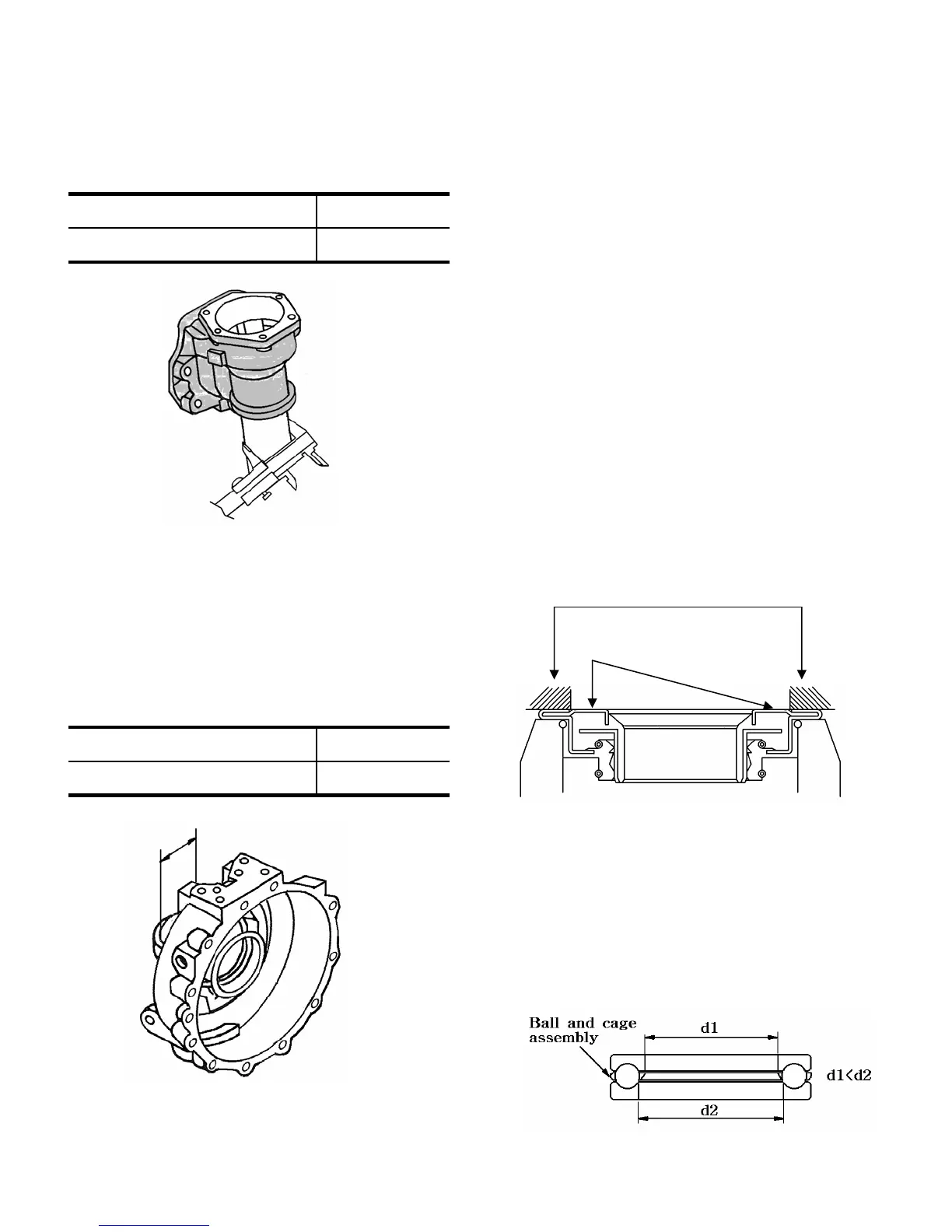

5)The flat-seat thrust bearing,as shown in

Fig.6-30,should be installed with the larger

bore side turned downwards.Also install the

ball-cage assembly as shown in the figure .

6-12

Fig.6-30

Loading...

Loading...