9-26

5.SAFETY VALVE( Optional)

5.1 GENERAL DESCRIPTION

With the chock closed completely by turning the

adjust screw tightly clockwise,the implement

mounted on the lift is held at a specified

height.While the tractor is traveling on roads in the

condition,there is a possibility that the cylinder

pressure will rise excessively when the implement

bounces.In such a situation the cylinder pressure

can rise so high as to break the cylinder.To prevent

such an accident,the relief valve works to leak off

the fluid in the cylinder to the tank via port P and

port T to decrease the cylinder pressure

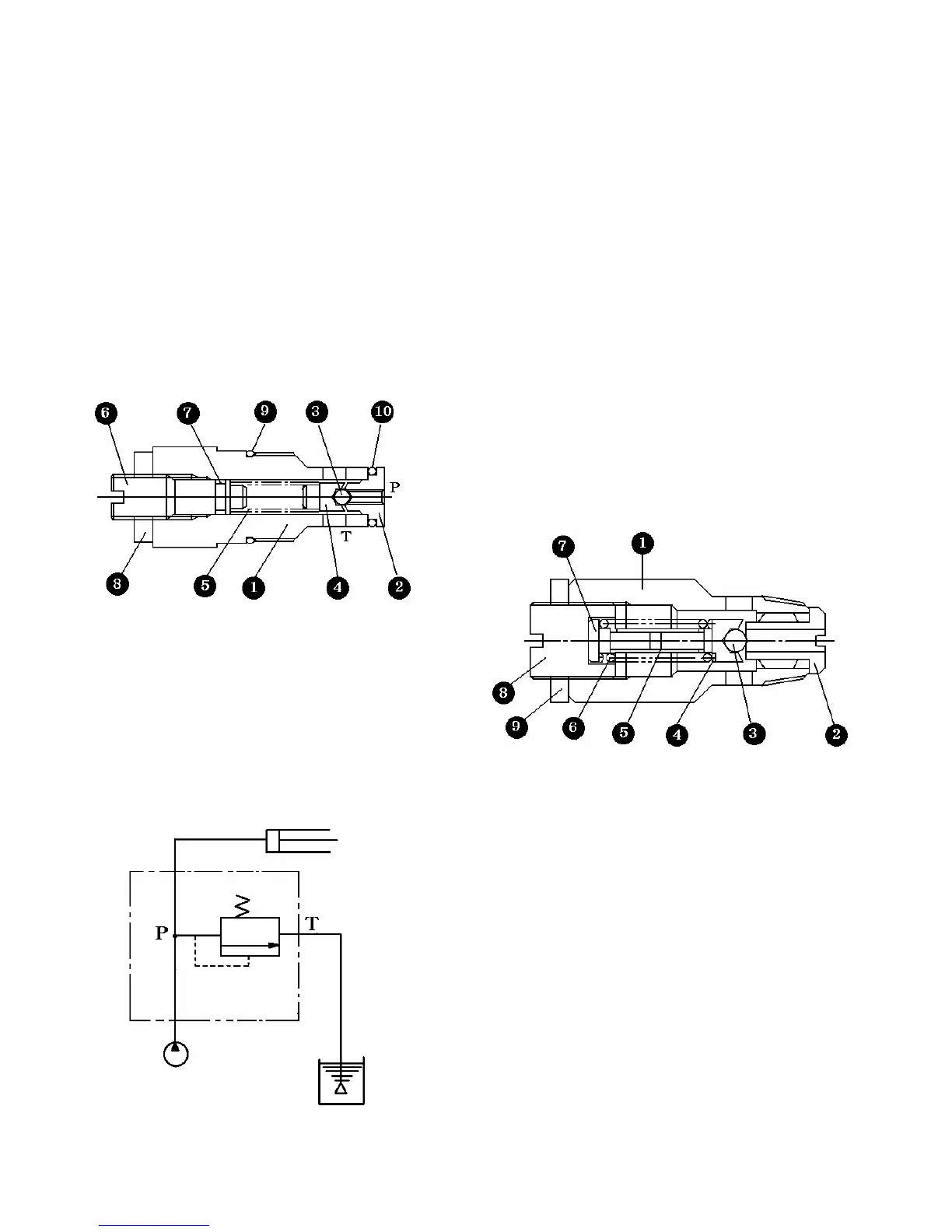

Fig.9-48

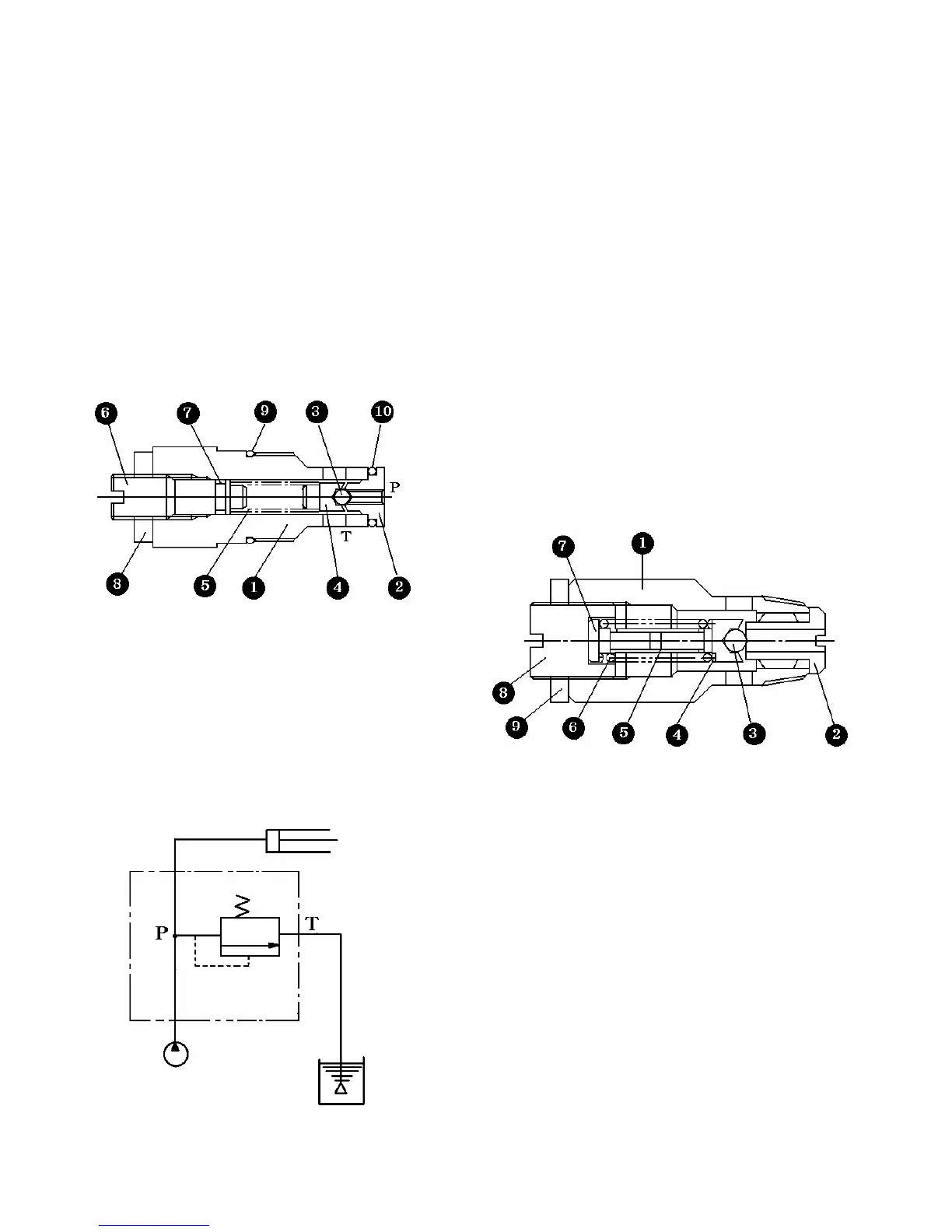

Circuit diagram

Fig.9-49

5.2 OPERATION

This valve is installed in the slow return check

valve circuit and able to be installed in the cylinder

case instead of Bolt.When the adjust screw of the

slow return check valve is closed completely,the

slow return check valve is completely closed.In this

condition,when the cylinder pressure exceeds the

regulated pressure of the relief valve: cracking

pressure,the fluid pushed up ball(3),overcoming the

force of spring(5).Then the surplus fluid is bled off

to the tank via port P and Port T.

6. RELIEF VALVE

1) GENERAL DESCRIPTION

This valve regulates the maximum pressure in

the whole hydraulic circuit.The regulated

pressure can be set with the adjust screw.

1.Body 2.seal 3.Ball 4.Spring seat

5. Spring 6.Adjust screw 7.O-ring

8.Lock nut 9.O-ring 10.O-ring

1.Body 2.seal 3.Ball 4.Spring seat

5. Sleeve 6.Spring 7.Spring stopper

8.Adjust screw 9.Lock nut

Fig.9-50

2) PRECAUTIONS FOR DISASSEMBLY

AND REASSEMBLY

(1)Tightening torque of lock nut (9)5.0∼6.0

㎏f·㎠(36.2∼43.4 ft.lbs)

(2)Install seat(2)and then tap ball(3)(5/16)

lightly so as to provide tight seating.

(3)Wrap the valve threads with sealing tape

and tighten the valve up to a specified

torque of 5-6Kgf.m(36-43 ft.lbs)

(4)Before disassembly, the current

screwing-in depth of the adjust screw

should be written down or memorized for

later reference.

Loading...

Loading...