9-23

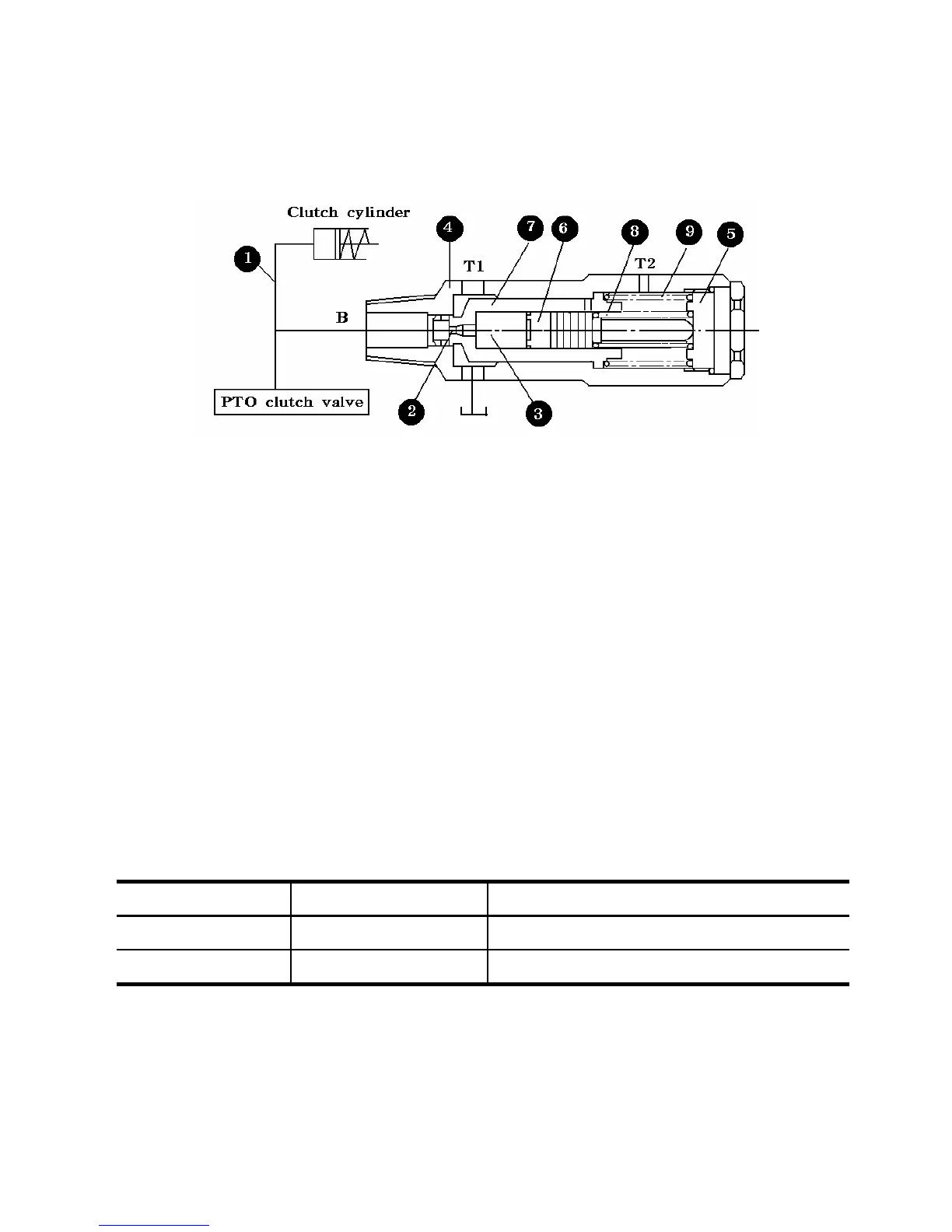

2) When the clutch is engaged completely

When the piston(6) moves to the end,there is no flow throgh chock(2) and the pressures in chamber

(3) and circuit(1) become equal,that is,the pressure which the plunger receives on both sides are the

same.Consequently,plunger(7) is pushed back to the left by the force of spring(9),which closes the

passage from port B to port T.With this,the pressure in circuit(1) starts rising at point P3 up to the

supplied pressure.Thus the clutch engagement is maintained.

Fig.9-44 When the clutch is completely engaged

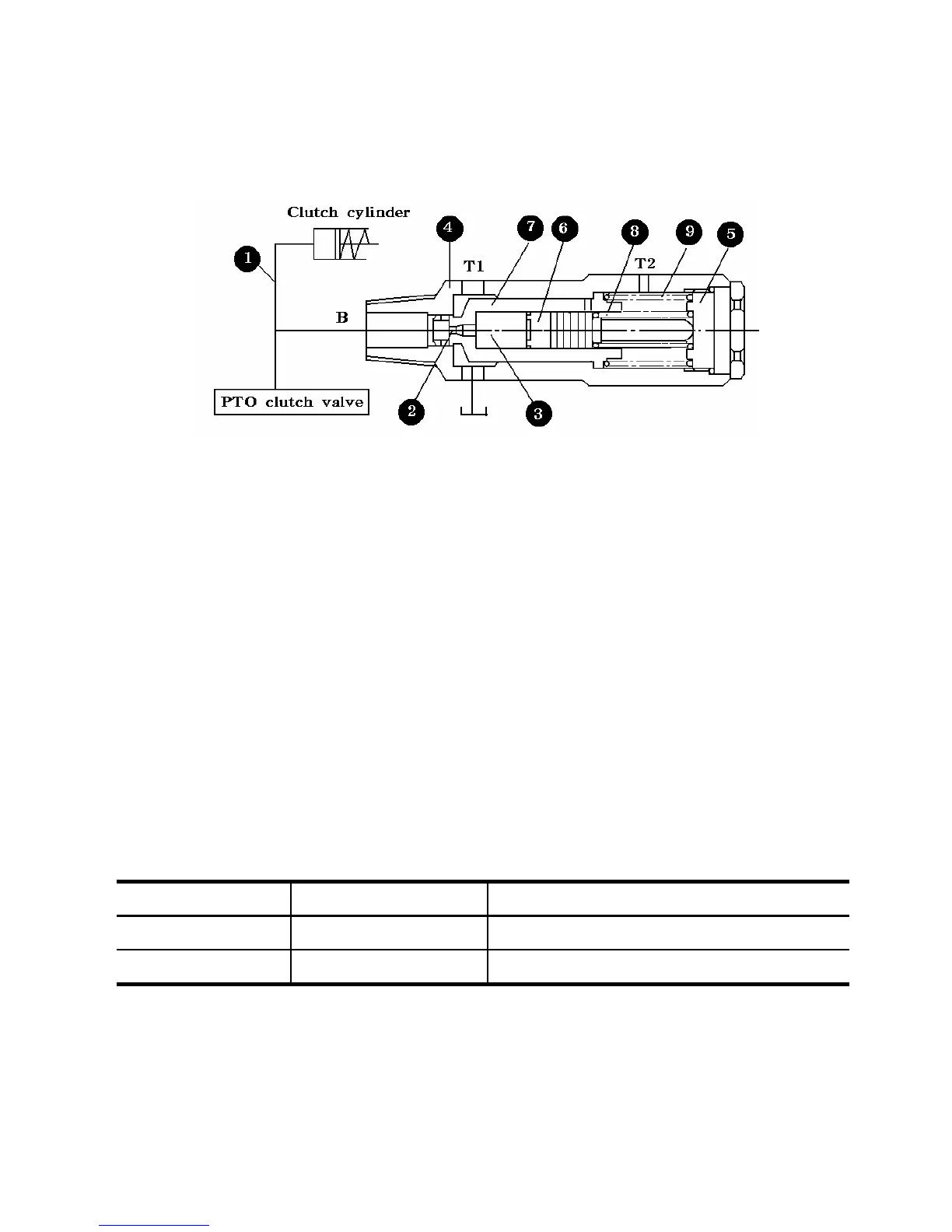

3.3 DISASSEMBLY AND INSPECTION

1) Required Tools

-24 mm box type wrench and torque wrench: for valve tightening

-22 mm box type wrench and torque wrench: for plug(5)

-Other required things:tweezers,sealing tape,rag,and oil stone

2) Disassembly

a. Detach the change cover and remove this valve assembly

b. Remove the plug(5) ,Take springs (9 and 8), and then extract piston(6) and plunger(7) by

tilting body(4).

3) Inspection of the disassemble parts.

Inspect the plunger and the piston for dents on their friction surfaces.Such flaws must be

corrected with oil stone.Wash all parts in fresh cleansing oil

4) Reassembly

a. Tightening torque

4.0-5.0(28.9-36.2)Plug(5)

4.5(32.6)Valve assembly*

Tightening torque[Kgf.m(ft.lbs)]Fastener NameRef.No

* The threads should not be wrapped with sealing tape.

b.Install plunger(7) into body(40 and confirm that the plunger moves smoothly.Then install

piston(6),spring(8),and spring(9) in order and tighten plug(5) to the specified torque.

Loading...

Loading...