9-13

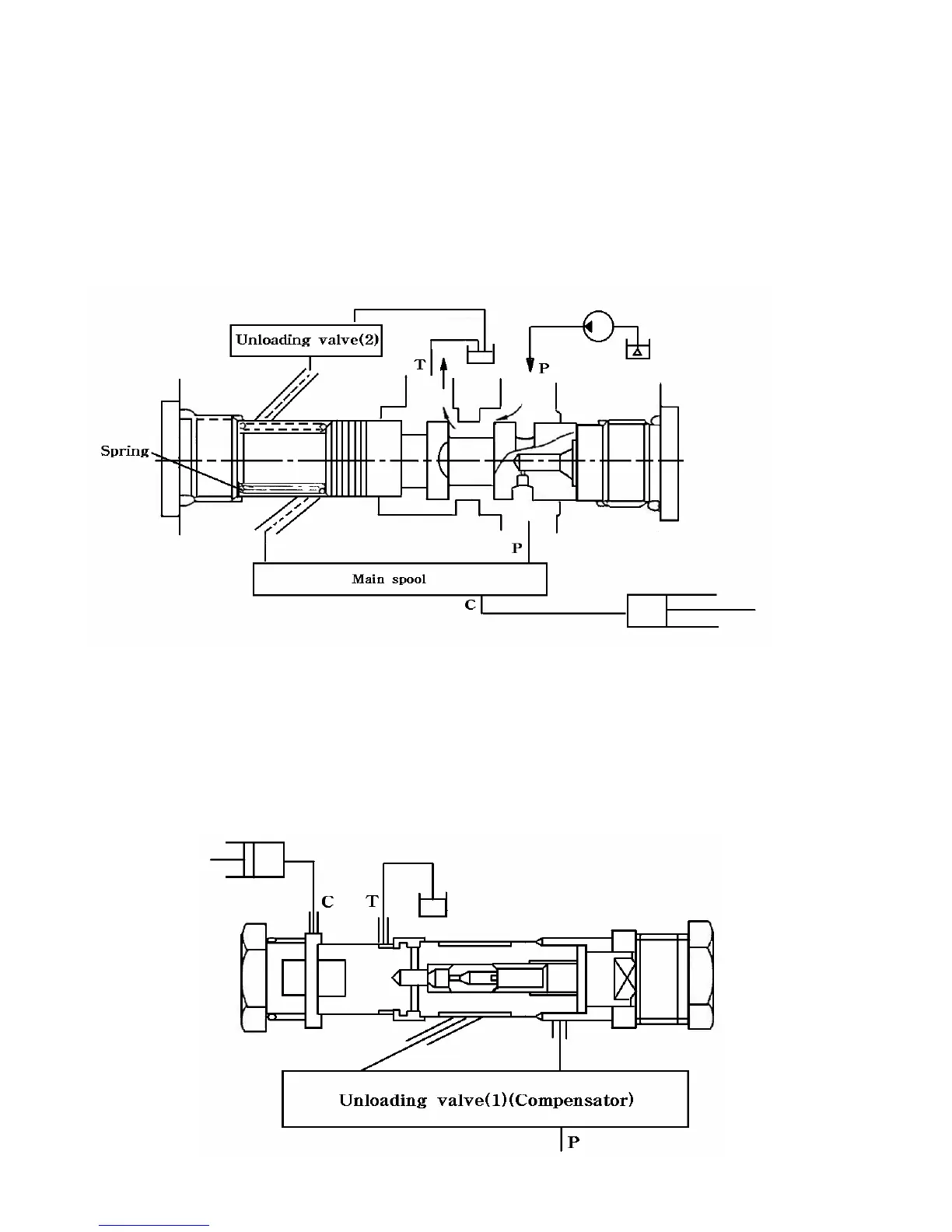

2) Unloading valve(1) (compensator)

it consists of the spool and spring.

While the main spool is neutral or in the lowering position,it diverts all the fluid from the pump

directly to the tank.In this state,the pump delivery pressure is regulated to be 7-8Kgf/㎠(100-114 psi)

To prevent engine power loss and fluid temperature rise.

When the main spool is set in the lifting position.it delivers the fluid whose volume is in proportion

To the opening to the port P-to C passage and surplus is diverted to the tank.Consequently only fluid

with volume corresponding to main spool displacement is allowed into the cylinder through port C,

Independent from fluctuations in cylinder pushing pressure and pump delivery pressure,which

making it possible to perform very subtle operations such as inching.Moreover,as the pump delivery

Pressure never exceeds the value of cylinder pushing pressure +7-8 Kgf/㎠(100-114 psi),pump

power loss in minimized.

Fig.9-20

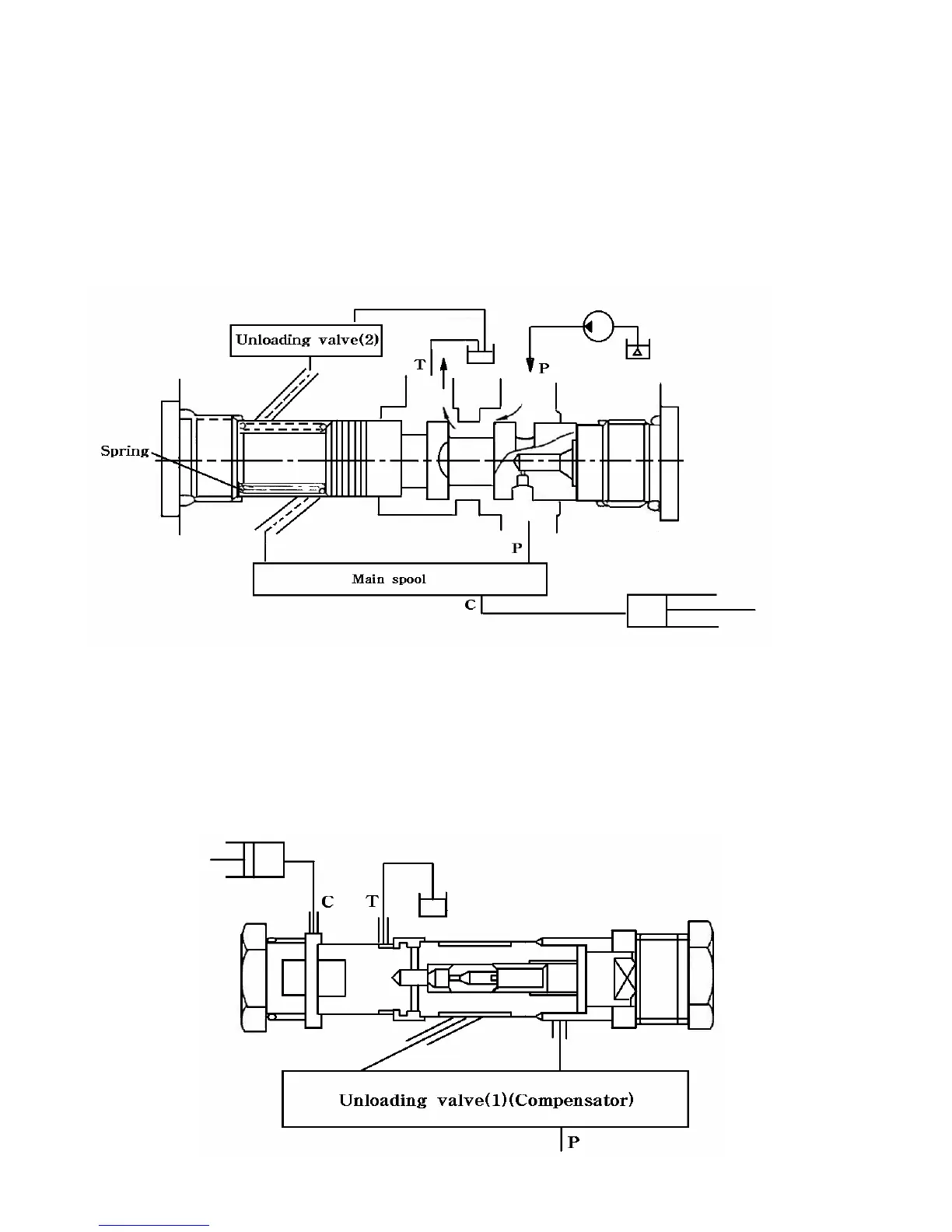

3) Unloading valve(2)

It consists of a spool,poppet (Ø0.5),spring and stopper bolt.This valve is installed to improve

unloading efficiency.It works as follows.

When the main spool is shifted from the lifting position to the neutral position,it diverts the unloading

pilot pressure to the tank,making use of port-C pressure.

Fig.9-21

Loading...

Loading...