9-19

1.5. SERVICING INSTRUCTIONS.

1) Required tools

-6mm set screw wrench and torque Wrench

-19mm spanner and torque wrench

-22mm spanner and screw wrench

-conventional screw driver[3mm(0.12 in) in

blade width]

-plastic rod [Ø10mm(Ø0.394 in)]

Oil stone,cleanser,tweezers,etc.

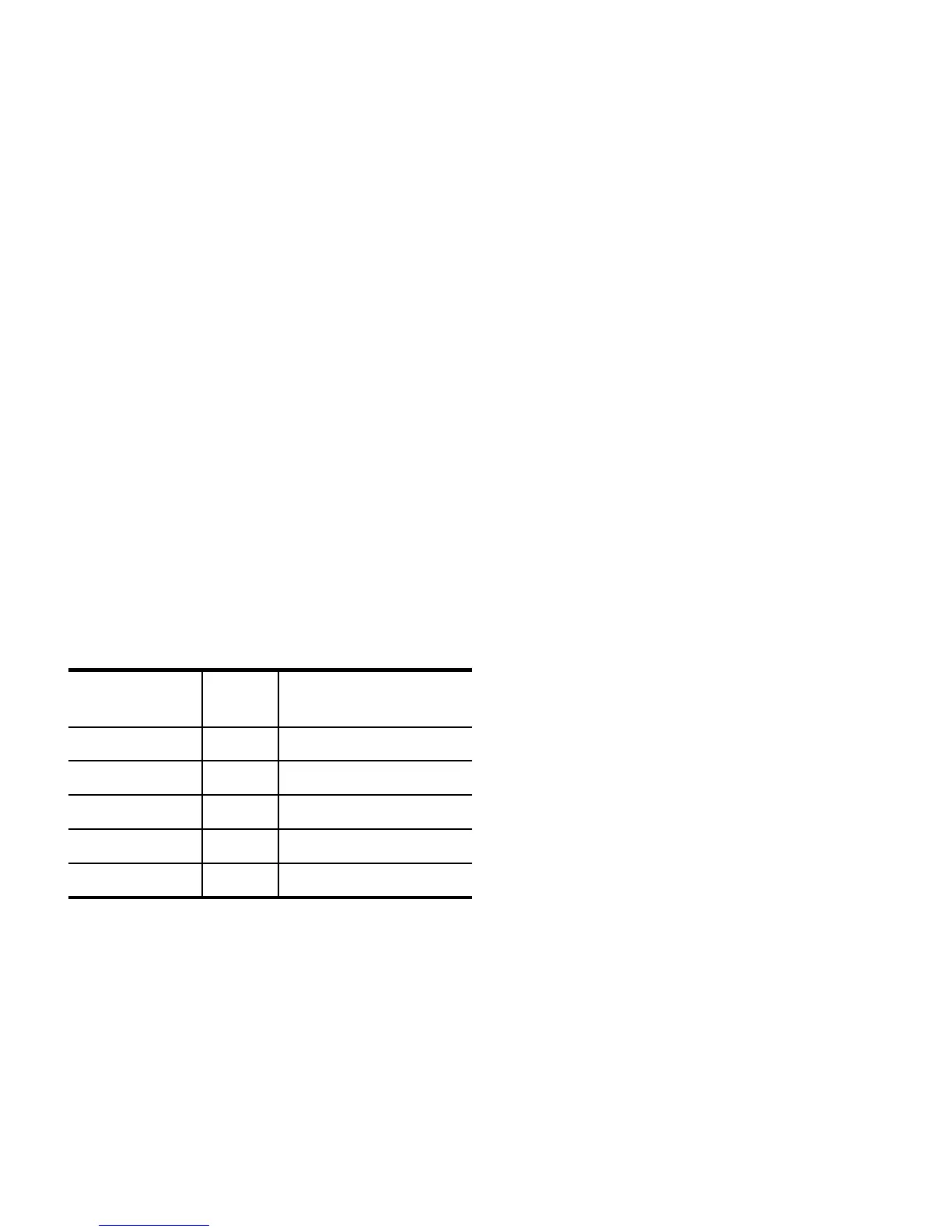

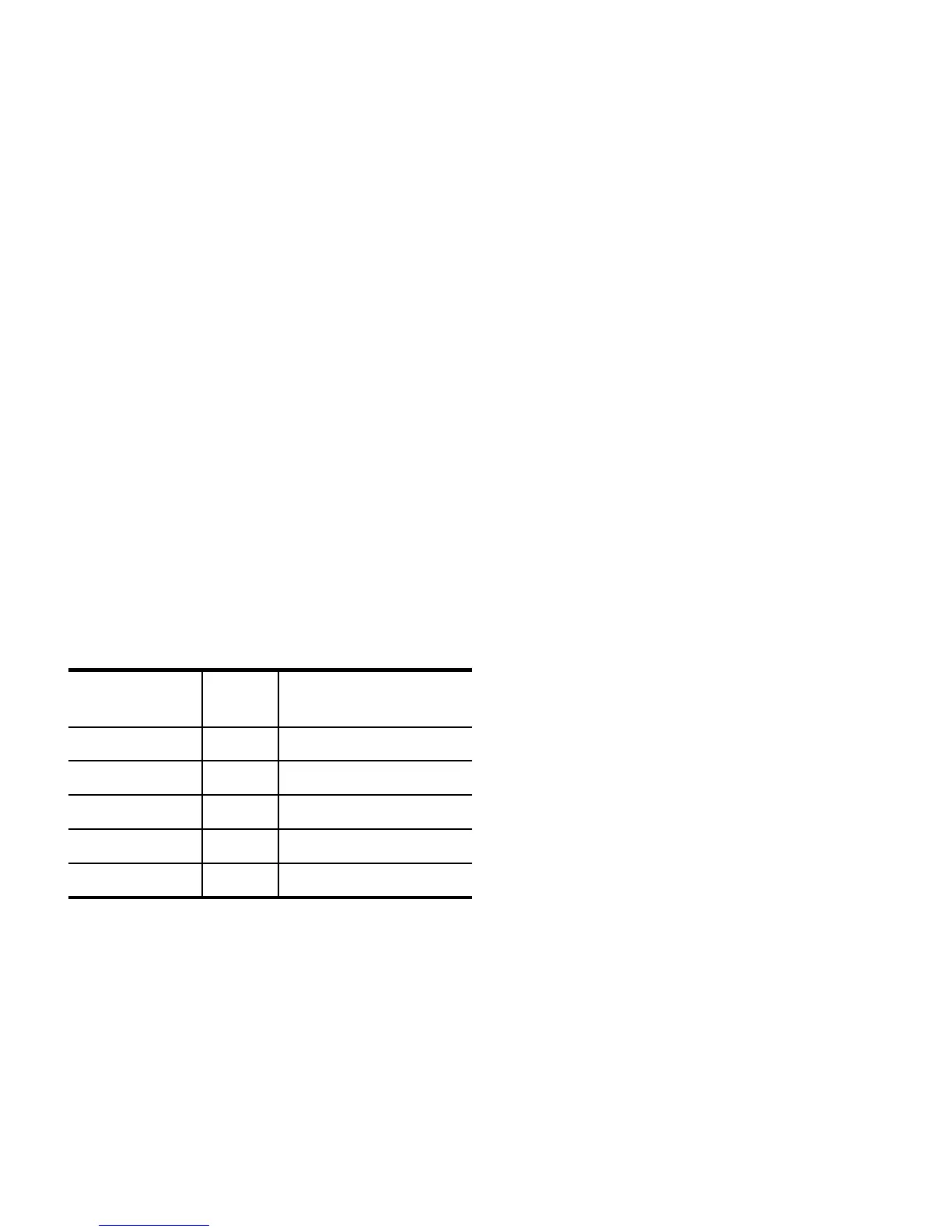

2) Tightening torque

2.5 (18.1)PT /4Sunk Plug

2.5 (18.1)M14Plug

0.8 (5.8)M6Stopper bolt

0.8 (5.8)M6Spool head

3.5 (25.3)M16Plug

Tightening torque

Kgf.m(ft.lbs)

SizeDescription

3) Disassembly

-Main spool and related parts.

Remove the snap ring E and draw out the main

spool carefully.

Note:

The main spool and spool head are screw-fitted,

so they can be separated from each other.But

they are tightened with adhesive applied,so they

should not be disassembled unless required.

-Holding check valve and related parts.

Remove the plug and take out the spring.The

poppet can come out only by slanting the casing,

and if not,remove it with pliers.

-Unloading valve(1): compensator

Remove the plugs from both sides and take out

the spring and spool.

-Unloading valve(2)

Remove the plugs from both sides and take out

the spring and spool.

Note:

The spool and stopper bolt are tightened with

each other with adhesive applied to their threads,

so they should not be separated unless required.

by removing the stopper bolt,the poppet and

spring can be taken out of the spool.

-Pilot spool and related parts.

Remove the plugs from both sides and take out

the spring and push rod.

The pilot spool set can be pushed out from the

push rod side with a Ø10 mm(Ø0.394 in) rod.

When pushing,put the rod on the sleeve,not the

spool.

Note:

The spool and sleeve cannot be separated from

each other.

4) Lifting to neutral shifting(unloading process)

While the piston is rising,the configuration of the control valve is the same as in the lifting position.

But when the piston stops rising at a required position,spool(A) returns to neutral position. In this

state,orifice(7) is closed and orifice (6) is opened,so the pressure in chamber(13) becomes lower than

that in chamber(15) and spool (B) (unloading valve 1) is shifted leftwards a little to let pump delivery

fluid flow out through orifice(35).As pump delivery pressure becomes lower than cylinder holding

pressure,passage(27) becomes higher than that in chamber(18).Consequently spool (H) (unloading

valve 2) is shifted rightwards and chamber(22) is connected to port T4,Chamber (13) is also connected to

port T4 through passage(16),chamber(19),orifice(20),chamber (21),and chamber(22),so the surplus

pressure in chamber(130 is released.In short when the control valve is shifted from the lifting position to

the neutral position,The pressure in chamber(13) on the right-hand side of spool(B) is forced to release to

port T4 and thus unloading operation is performed positively.

Loading...

Loading...