Servicing and maintenance intervals

Clean ......................................................... daily, more frequently if in continuous operation

Oil level (thread lubrication/hook lubrication)...............................................daily, before use

Oil the hook.................................................................................................daily, before use

Lubricate the bevel gears ................................................................................... once a year

Check/adjust air pressure ............................................................................daily, before use

Clean air filter of air-filter/lubricator ................................................................when required

These maintenance intervals are calculated for the average running time of a

single shift operation. If the machine is operated more than this, shorter inter-

Clean the hook, hook compartment and toothed wheel 3 daily, several times if in

continuous use.

Switch the machine off!

Danger of injury if the machine

is started accidentally!

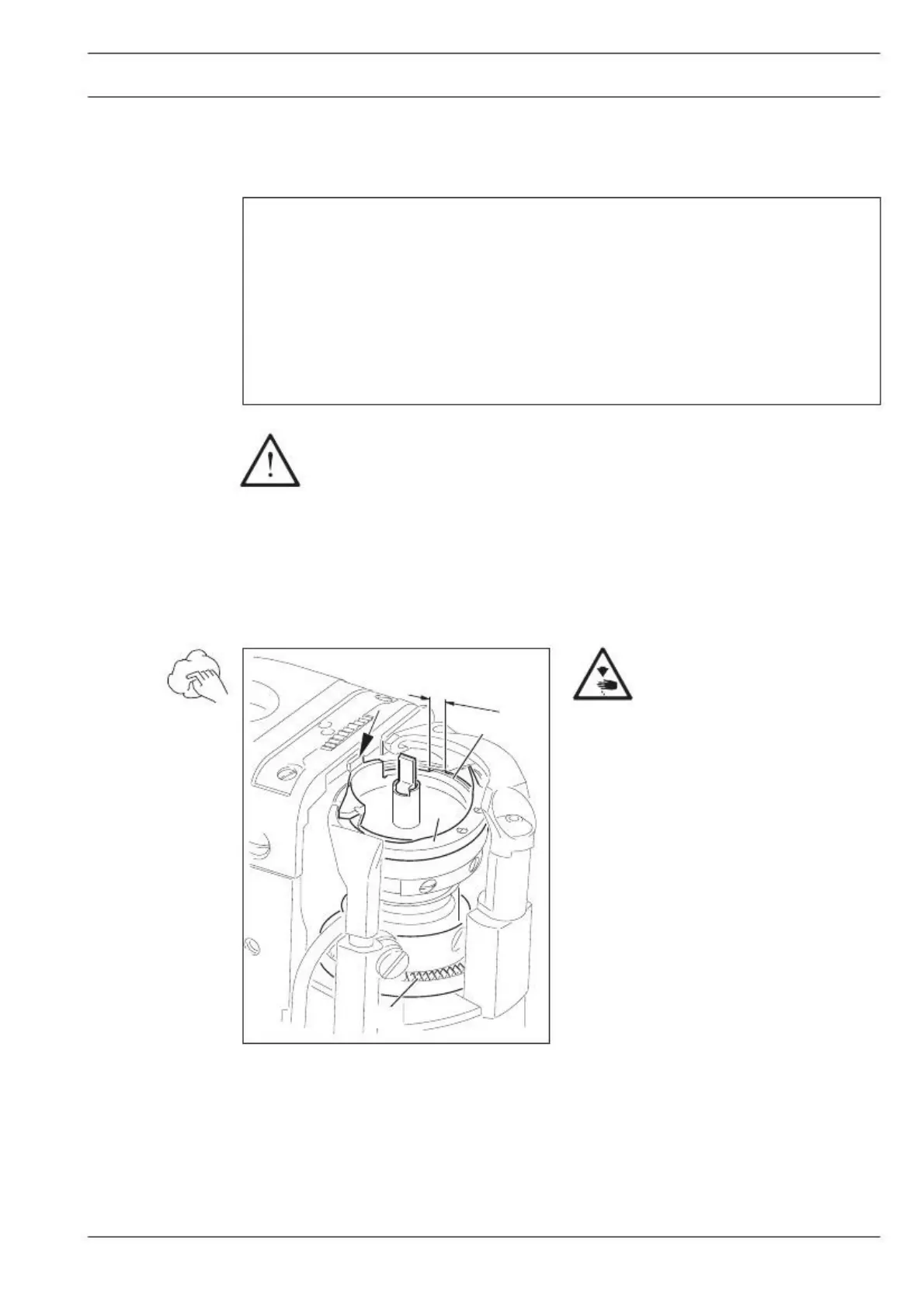

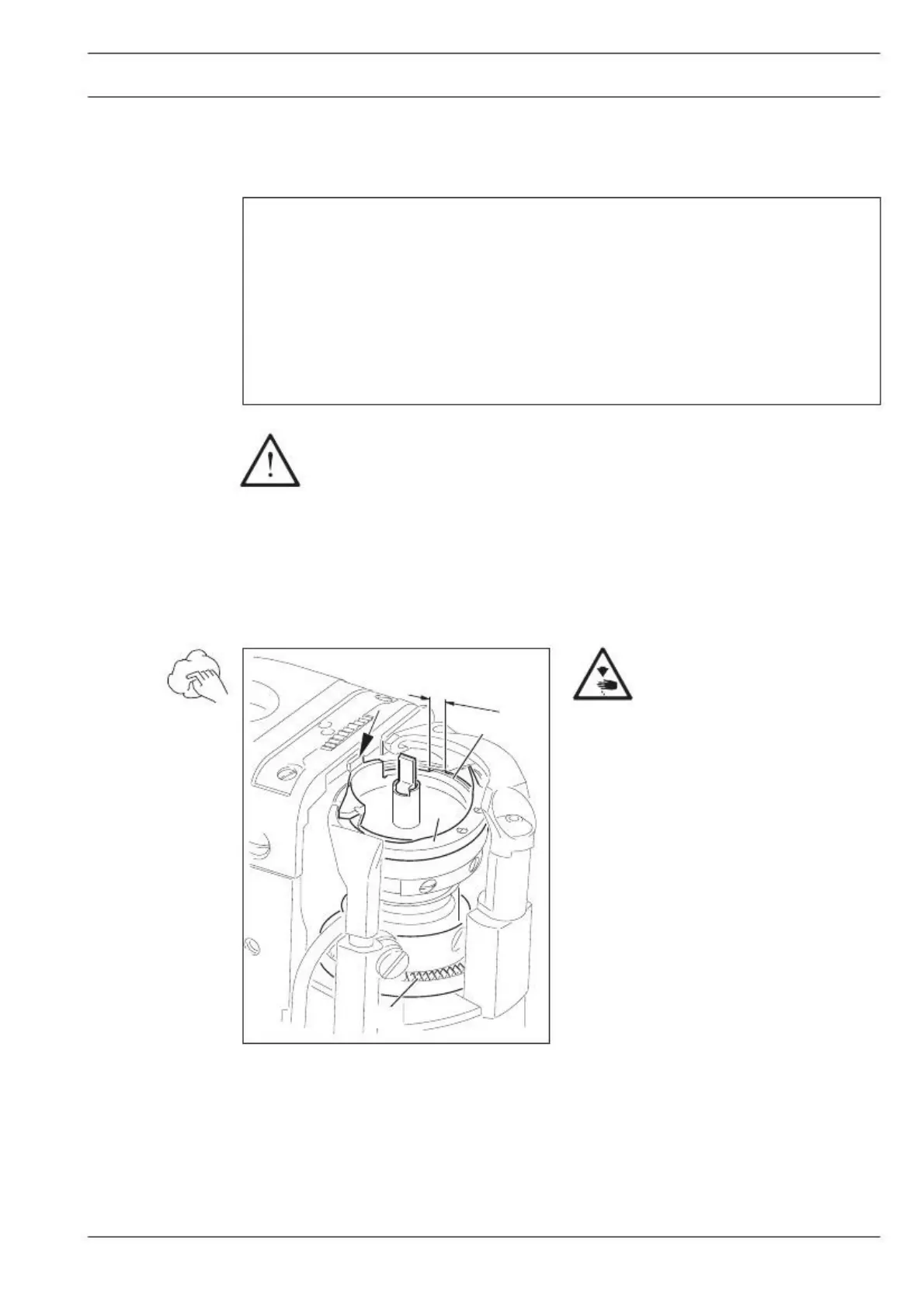

● Bring the needle bar to its highest posi-

tion.

● Open the post cap and remove the bob-

bin case cap and the bobbin.

● Turn the handwheel until the point of

bobbin case 2 penetrates into the groove

of the hook race approx. 5 mm.

● Clean the hook race with paraffin.

● When inserting the bobbin case 2, ensu-

re that the horn of the bobbin

● case 2 engages in the groove of the

needle plate.

● Screw hook gib 1 back on and close the

post cap.

Loading...

Loading...