5

vacon • 76 Installation

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

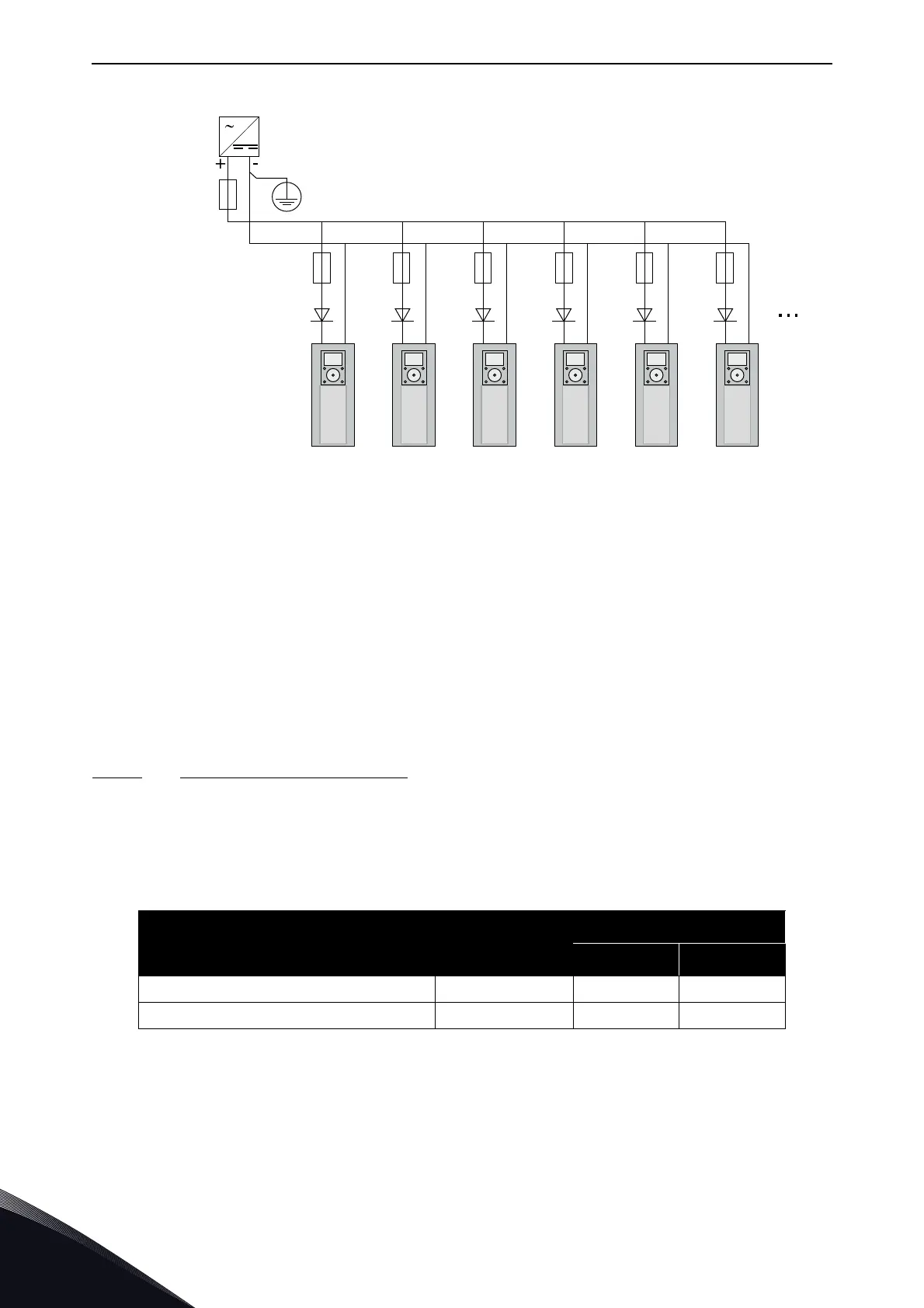

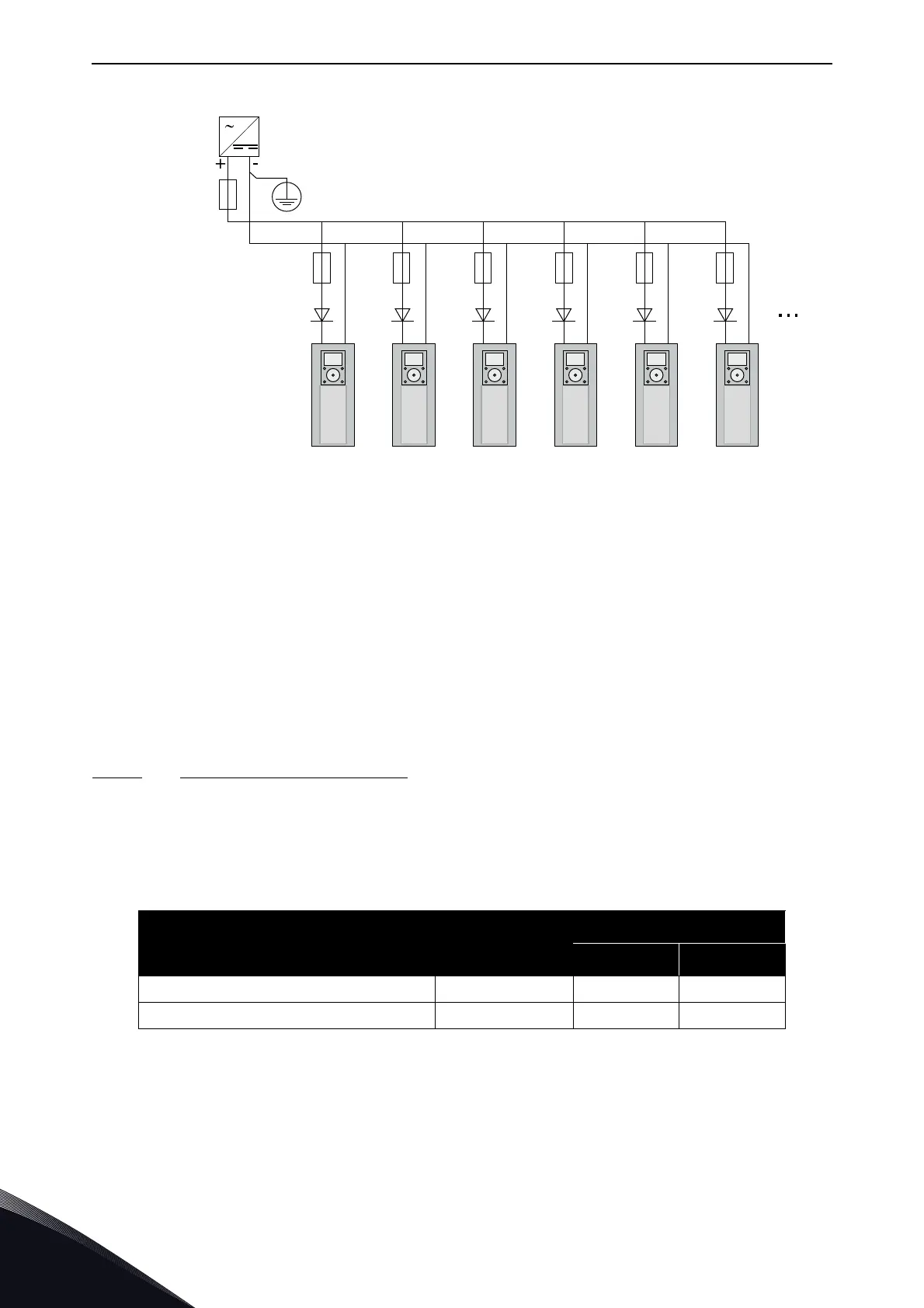

Figure 47. Parallel connection of 24 V inputs with many AC drives

NOTE! The control unit I/O ground is not isolated from the chassis ground / protective earth. In the

installation, take into account the potential differences between the grounding points. We

recommend that you use galvanic isolation in the I/O and 24V circuitry.

NOTE! Analogue outputs and inputs do not work with only +24V supplied to the control unit.

If there is a +24V/EXT+24V output on the board, it is locally short-circuit protected. If one of the +24V/

EXT+24V outputs short-circuits, the others remain powered because of the local protection.

5.4.3 Control unit cabling

The OPTA1 basic board has 20 control terminals, and the relay board has 6 or 7. You can see the

standard connections of the control unit and the descriptions of signals in Figure 48.

5.4.3.1

Selection of the control cables

The control cables must be a minimum of 0.5 mm

2

(20 AWG) screened multicore cables. The

terminal wires must be a maximum of 2.5 mm

2

(14 AWG) for the terminals of the relay board and

1.5 mm

2

(16 AWG) for other terminals.

Table 31. The tightening torques of the control cables

The terminal

The terminal

screw

The tightening torque

Nm lb-in.

Relay and thermistor terminals M3 0.5 4.5

Other terminals M2.6 0.2 1.8

PE/GND

-G1

Ext +24VDC

Power Supply

-F1

#6 #7 #6 #7 #6 #7 #6 #7 #6 #7 #6 #7

-F2

1A

gG/

Class CC

-Q1

3A

-Q2

3A

-Q3

3A

-Q4

3A

-Q5

3A

-Q6

3A

-F3

1A

gG/

Class CC

-F4

1A

gG/

Class CC

-F5

1A

gG/

Class CC

-F6

1A

gG/

Class CC

-F7

1A

gG/

Class CC

Loading...

Loading...