AIR N ARC

®

200 SERIES ALL-IN-ONE POWER SYSTEM

®

SECTION 6: MAINTENANCE

090019-OP_r0 PAGE - 57

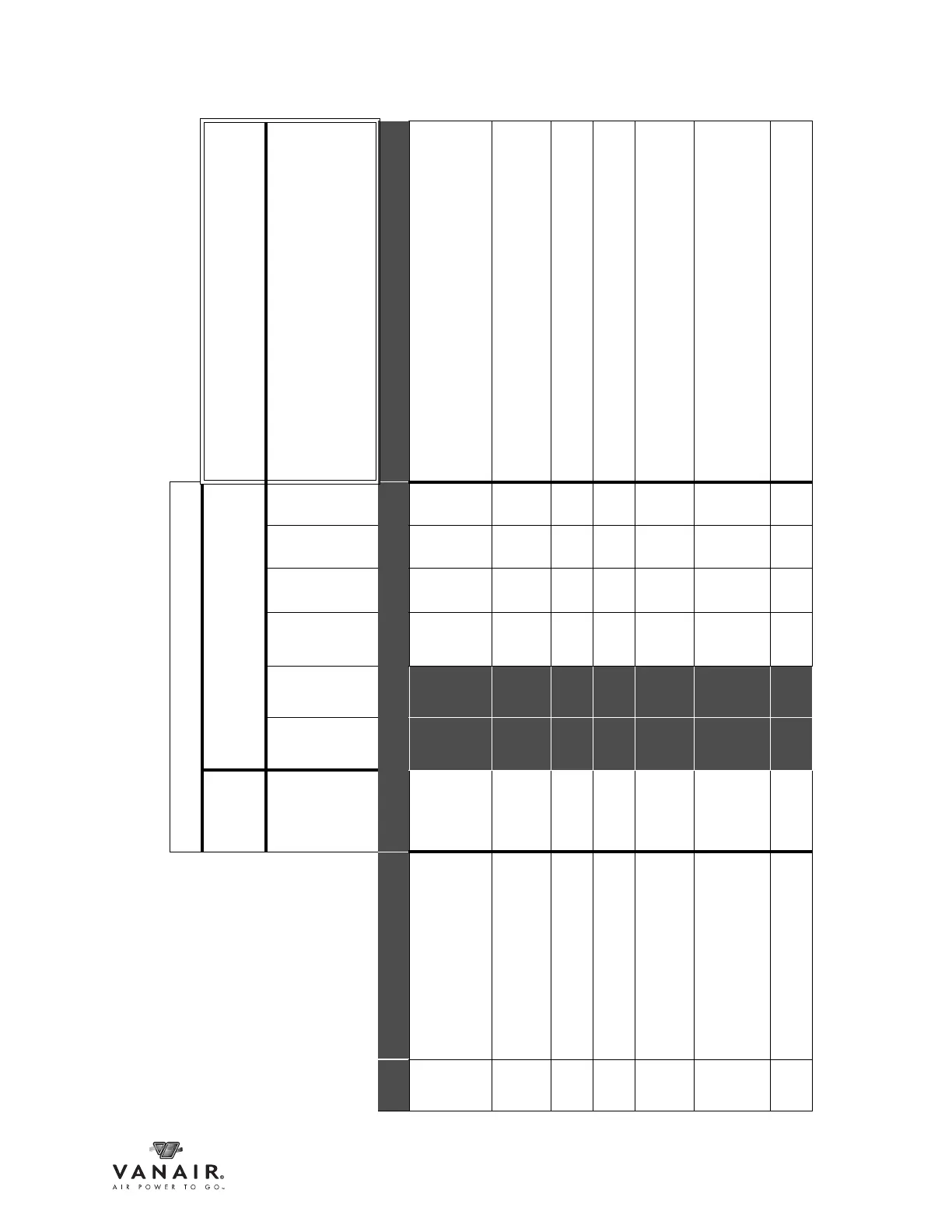

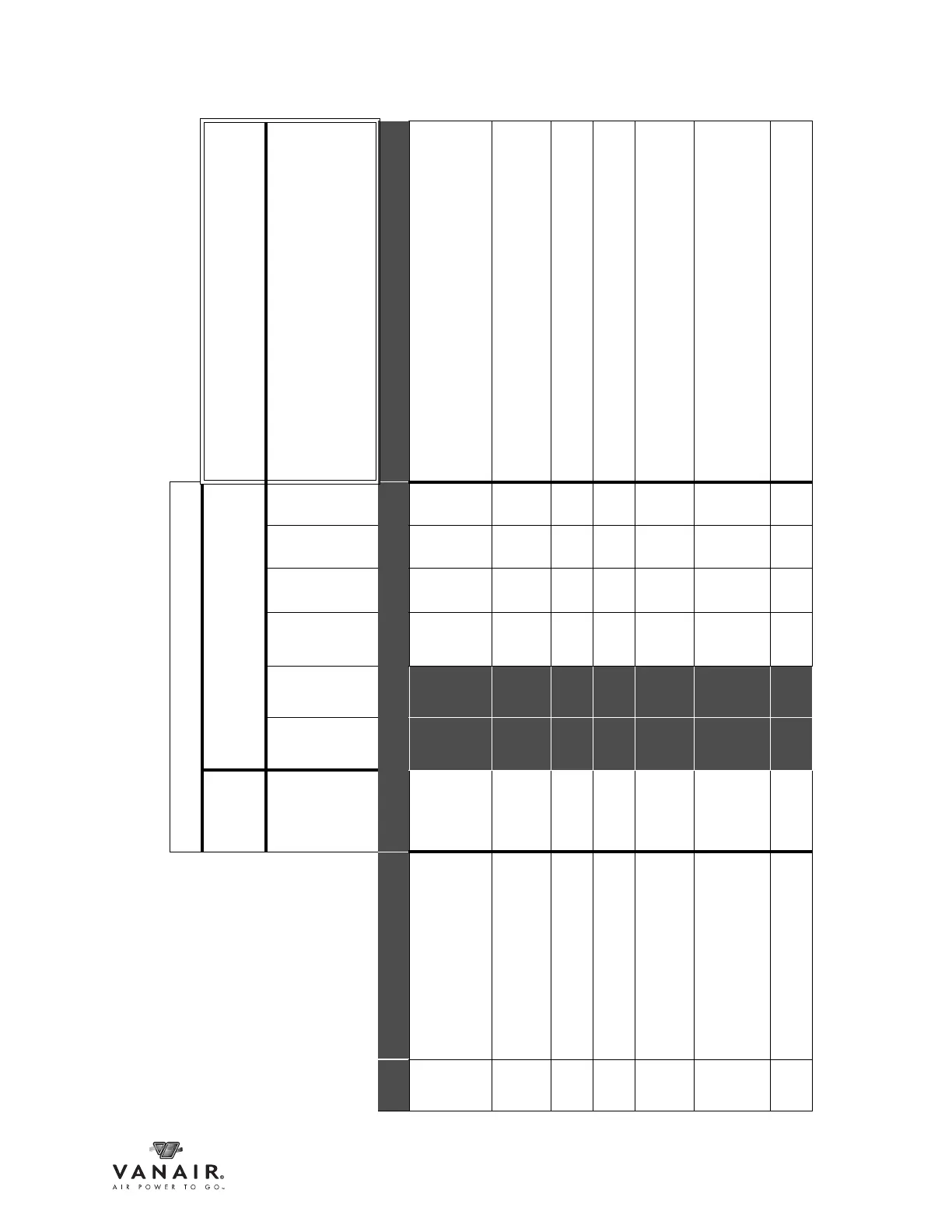

6.3 MAINTENANCE SCHEDULE TABLE

INTERVALS

BREAK-

IN

PERIOD

MAINTENANCE SCHEDULE

Hourly or Calendar Period - whichever

comes first

NOTE

First 20

Hours of

Operation

After 8

Hours or

Daily

After 40

Hours or

Weekly

Every 100

Hours or

One Year

Every 200

Hours

After 600

Hours

After 1000

Hours

If working in dusty or dirty conditions, reduce the

recommended time intervals between servicing by

half for engine and compressor oil change, and

engine and compressor filter servicing.

KEY TASK DESCRIPTION

ACTION TO TAKE

1

Check tension of both

compressor poly-link drive

belts

• • ••••

Tighten belts if necessary. Consult Section 6.5.7,

Replacing and Re-tensioning the Compressor and/

or Generator Drive Belts, and its sub-sections that

concern the compressor drive belts.

2

Change engine oil and engine

filter

• ••••

Consult Section 6.5.9.2, Checking the Engine Oil,

and if necessary, to change the oil and oil filter refer to

Section 6.5.9.3, Replacing the Engine Oil.

3

Wash engine air pre-cleaner

• • • ••••

Remove and wash engine air filter precleaner: Consult

Section 6.5.9.1, Engine Air Filter Maintenance.

4

Change compressor oil

• ••••

Consult the following Sections 6.5.2, Compressor Oil

Maintenance.

5

Check engine oil level

• • ••••

Consult Section 6.5.9.2, Checking the Engine Oil,

and if necessary, to change the oil and oil filter refer to

Section 6.5.9.3, Replacing the Engine Oil.

6

Check and maintain oil level

at proper amount shown in

the compressor sight glass

• • ••••

Compressor must operate at oil levels within the

parameters of the sight glass, per Section 6.5.2,

Compressor Oil Maintenance. Do not overfill, or

operate at low levels.

7

Check air tank for water

accumulation

• • ••••

Drain any water from the air tank, per procedure in

Section 6.5.8, Draining the Air Tank.

Loading...

Loading...