Introduction ]VaporTEK Pump Certifications & Markings

6

VaporTEK Pump Certifications & Markings

Safety Certification

Certificates can be obtained upon request. The IECEx certificates can be obtained Online at:

http://iecex.iec.ch/

Hazardous Area Installation Instructions

1. VaporTEK Pump may be used with flammable gases and vapors with apparatus group II and temperature

class T3.

2. VaporTEK Pump is certified for maximum operating ambient temperature of +55°C.

3. The VaporTEK Pump is equipped with a temperature cut-off switch for thermal protection.

4. The VaporTEK Pump assembly certificate number has an “X” suffix, indicating that special conditions are for

safe use application:

When the vapor recovery pump is used as a flame arrester in vapor recovery pipes and a separate flame ar-

rester is not fitted, the following maximum hose and pipe lengths are permitted between the filler nozzle and

the vacuum pump according to EN13463-1 standard:

• Vapor recovery hose with an inside diameter < 10mm in the coaxial hose < 6m, or,

• Coaxial hose < 6m with an outside diameter < 38mm and fitted together with a downstream pipeline DN 15

(G 1/2) <

3m.

In addition, the tanks mentioned in Test Reports PTB Ex 05-45017 and PTB Ex 05-45027 may be installed in

the DN 15 (G 1/2) pipeline at a distance of between 0.3m and 2.5m in front of the VRP2 vapor recovery

pump. The pipeline between hose and tank shall have a minimum length of 0.5m.

The ambient temperature and the temperature of the fuel vapor/air mixture taken in shall remain within the tem-

perature range -20°C to +55°C at the intake end.

Flame paths shall not be repaired or reworked.

Equipment Marking

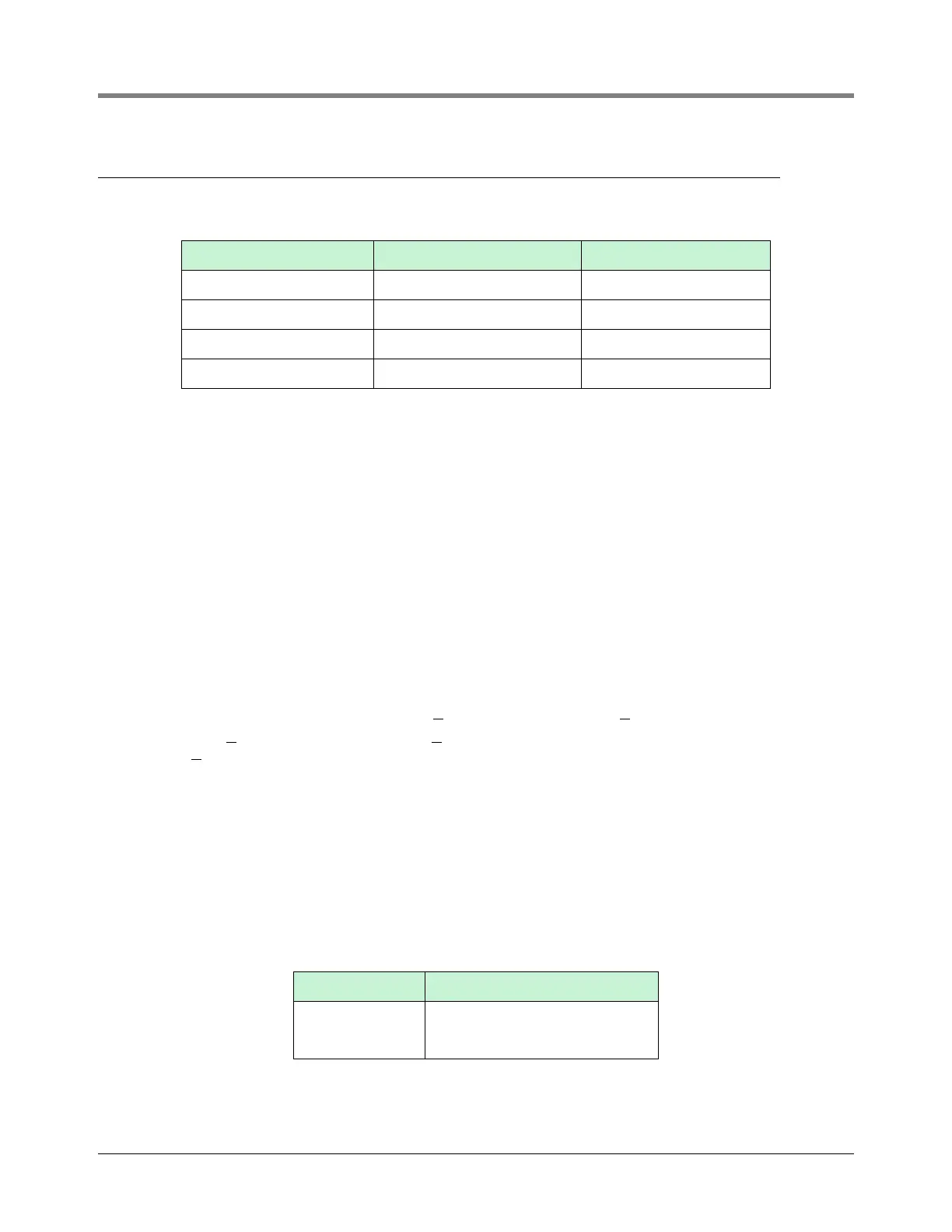

Product ATEX IECEx

VaporTEK Pump CML 18ATEX6243X N/A

VaporTEK Controller N/A N/A

VRP2 Pump CML 18ATEX1245X N/A

VRM2 Motor CML 18ATEX1244X IECEx CML 18.0116X

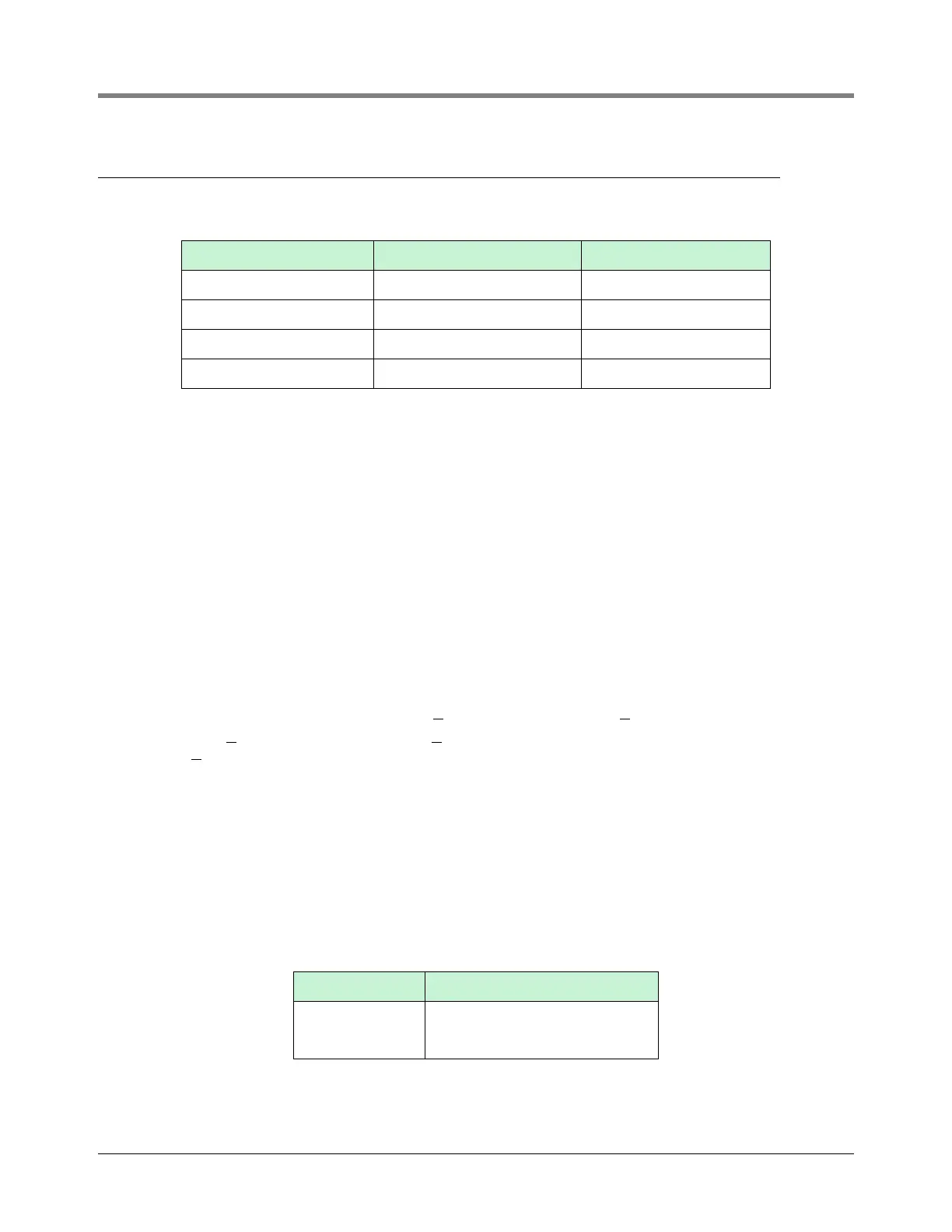

Product ATEX/IECEx

VaporTEK Pump

Ex db IIA T3 Ga/Gb

e II 1/2 G c d Ta=55°C

Loading...

Loading...