Introduction VaporTEK Pump Configuration

18

VaporTEK Pump Configuration

The VaporTEK Pump can be configured to operate in either a 2-Speed or a Variable-speed mode depending on

the configuration type and available dispenser inputs/signals.

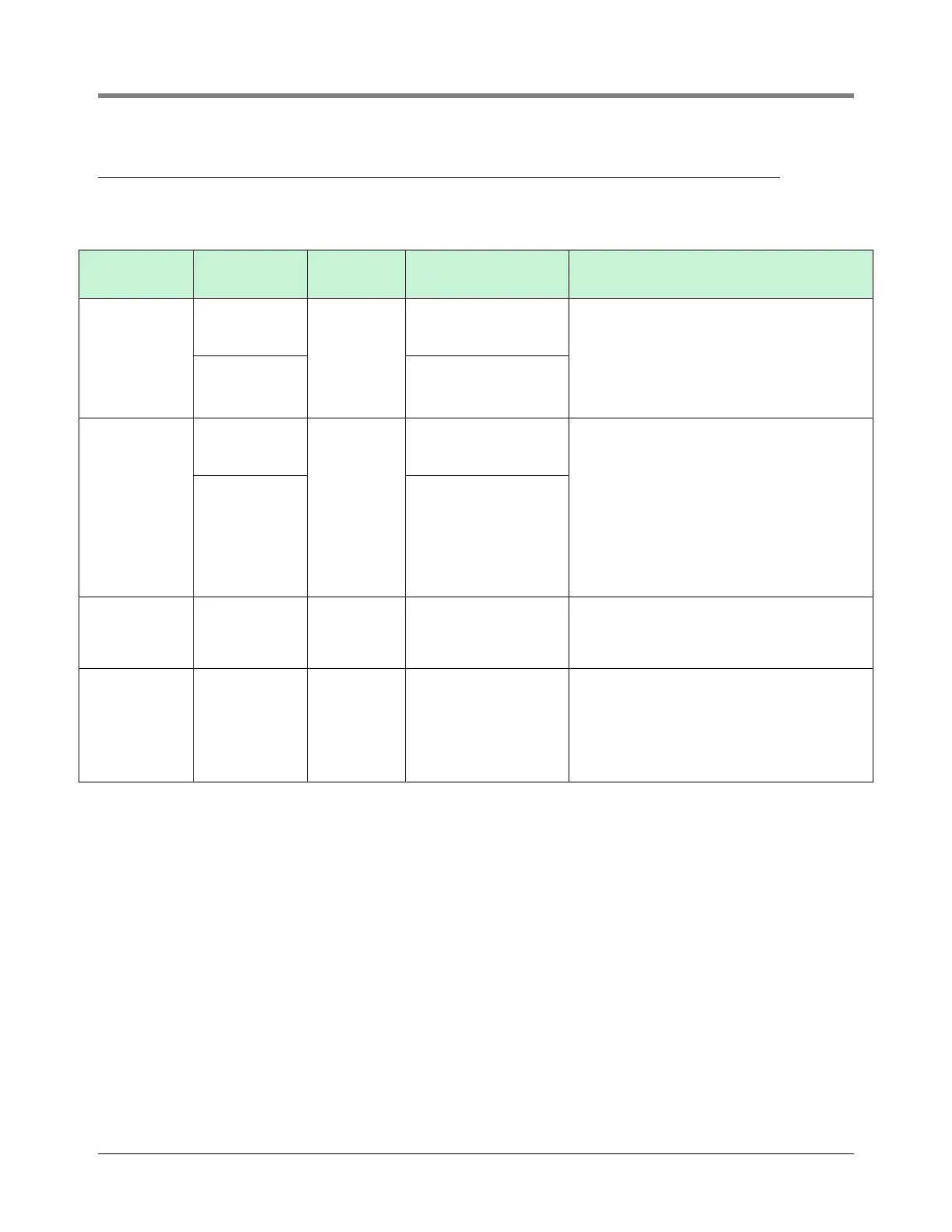

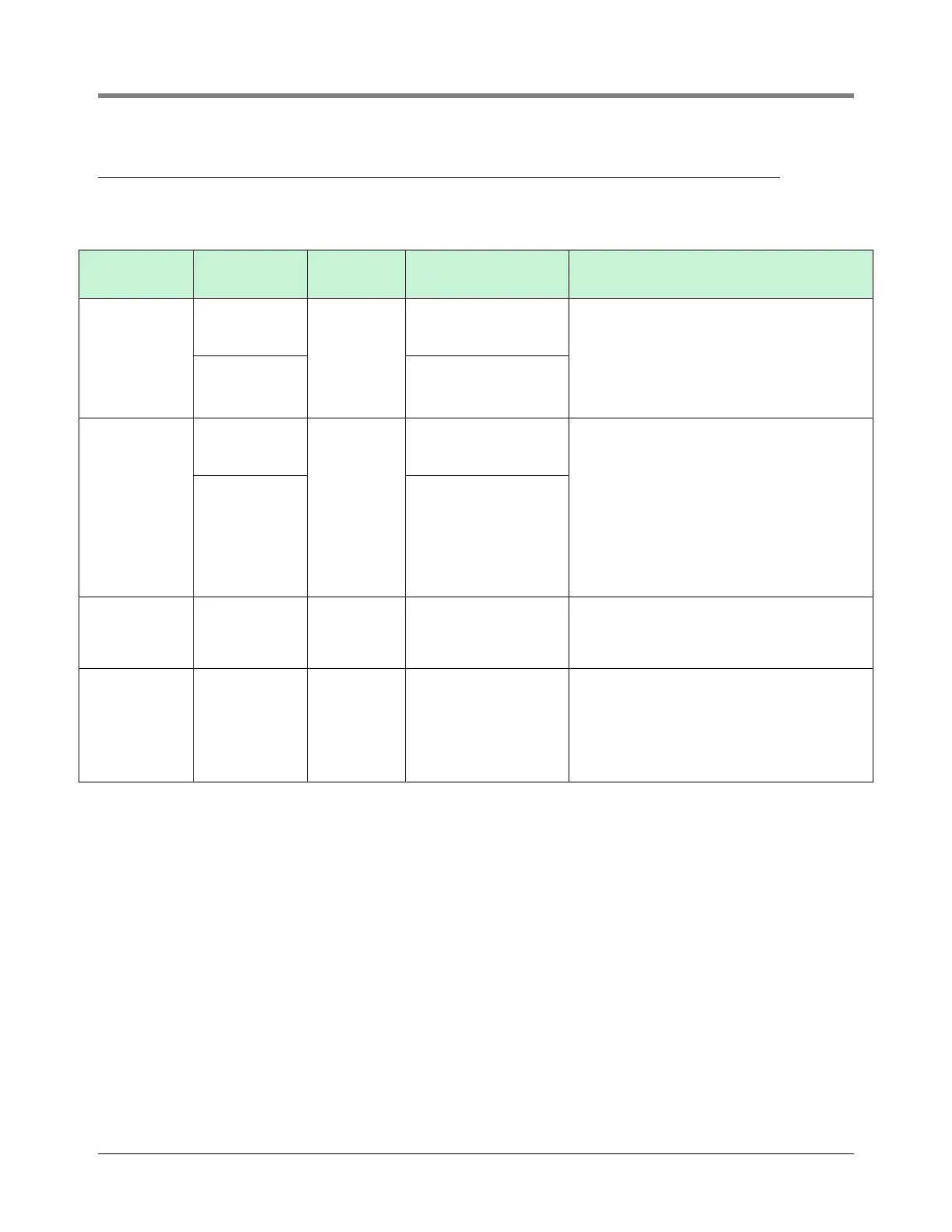

VaporTEK

Configuration

Input Type

Mode of

Operation

Required

Components

Method of Operation

Basic

High voltage

hook signal

(110-240VAC)

Two Speed

VaporTEK-3 Controller

The VaporTEK Controller receives nozzle hook

signals from either side of the dispenser.

With one fueling point active, the pump operates

in low speed. With two fueling points active, the

pump operates in high speed.

Low voltage

hook signal

(0-24VDC)

VaporTEK-3 Controller,

High Voltage Relay

Enhanced

High voltage

hook signal

(110-240VAC)

Two Speed

VaporTEK-3 Controller,

MPV10

In this configuration a high voltage hook signal

from either side of the dispenser operates a

relay switch which in turn control’s the high volt-

age input to the Vapor TEK Controller.

Note: One relay switch is required for each

gasoline nozzle in the dispenser.

With one fueling point active, the pump operates

in low speed. With two fueling points active, the

pump operates in high speed. This configuration

is typically used for multi-product dispensers

with low voltage hook signals.

Low voltage

hook signal

(0-24VDC)

VaporTEK-3 Controller,

MPV10,

High Voltage Relay

Plus

Liquid pulse

signal or serial

communication

line

Variable

Speed

VaporTEK-3 Controller,

Pulse Interface

(optional)

VaporTEK-3 Controller receives the fuel flow

information via serial data line or calculates the

flow value using pulse inputs. This value will be

used to control the motor speed.

Ultra

Liquid pulse

signal or serial

communication

line

Variable

Speed

VaporTEK-3 Controller,

Valve Interface and EPV

10

Pulse Interface

(optional)

VaporTEK-3 Controller receives the fuel flow

information via serial data line or calculates the

flow value using pulse inputs. This value will be

used to control the motor speed. An additional

connected Valve Interface along with two EPV’s

controls the A/L – Ration during a simultane-

ously transaction.

Loading...

Loading...