Introduction VaporTEK Controller

14

VaporTEK Controller

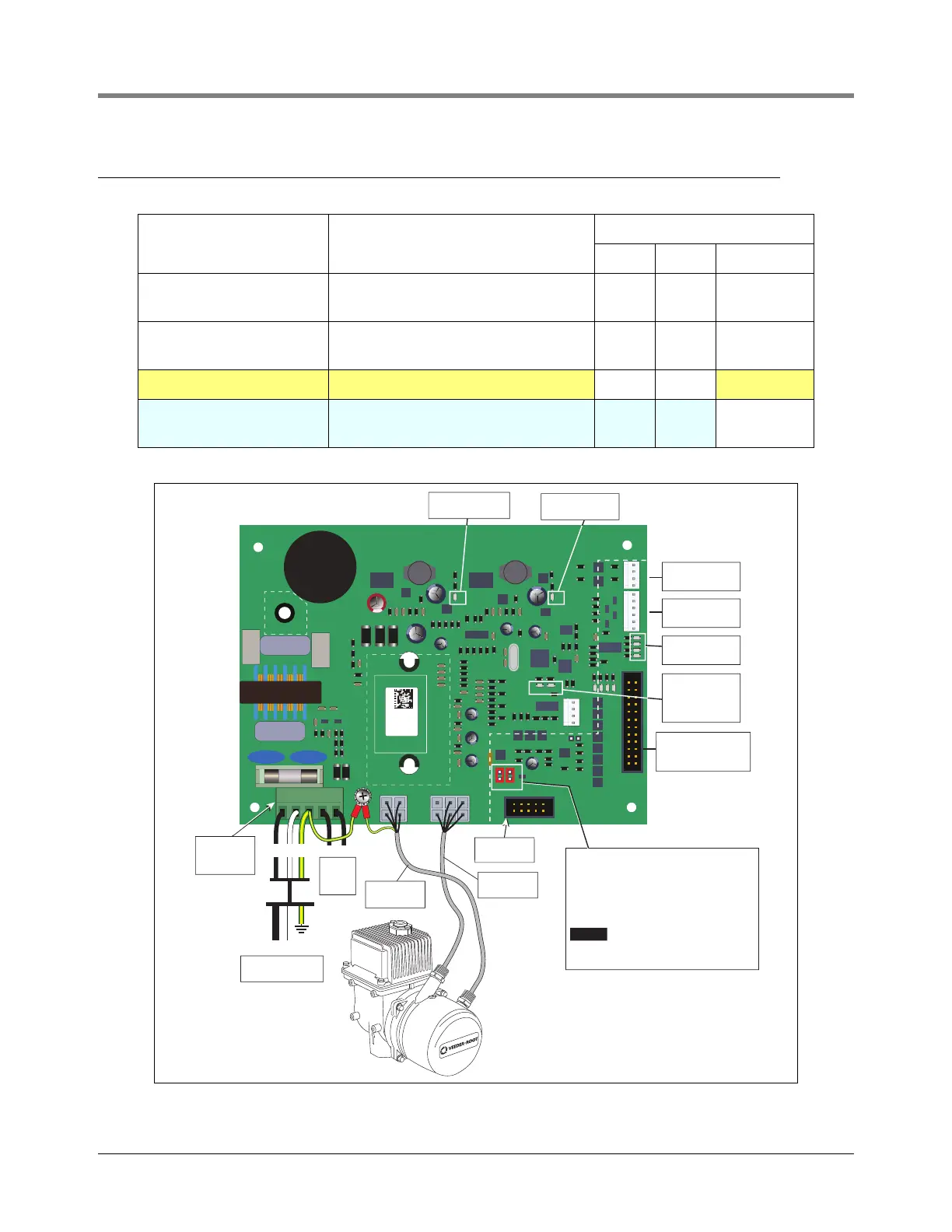

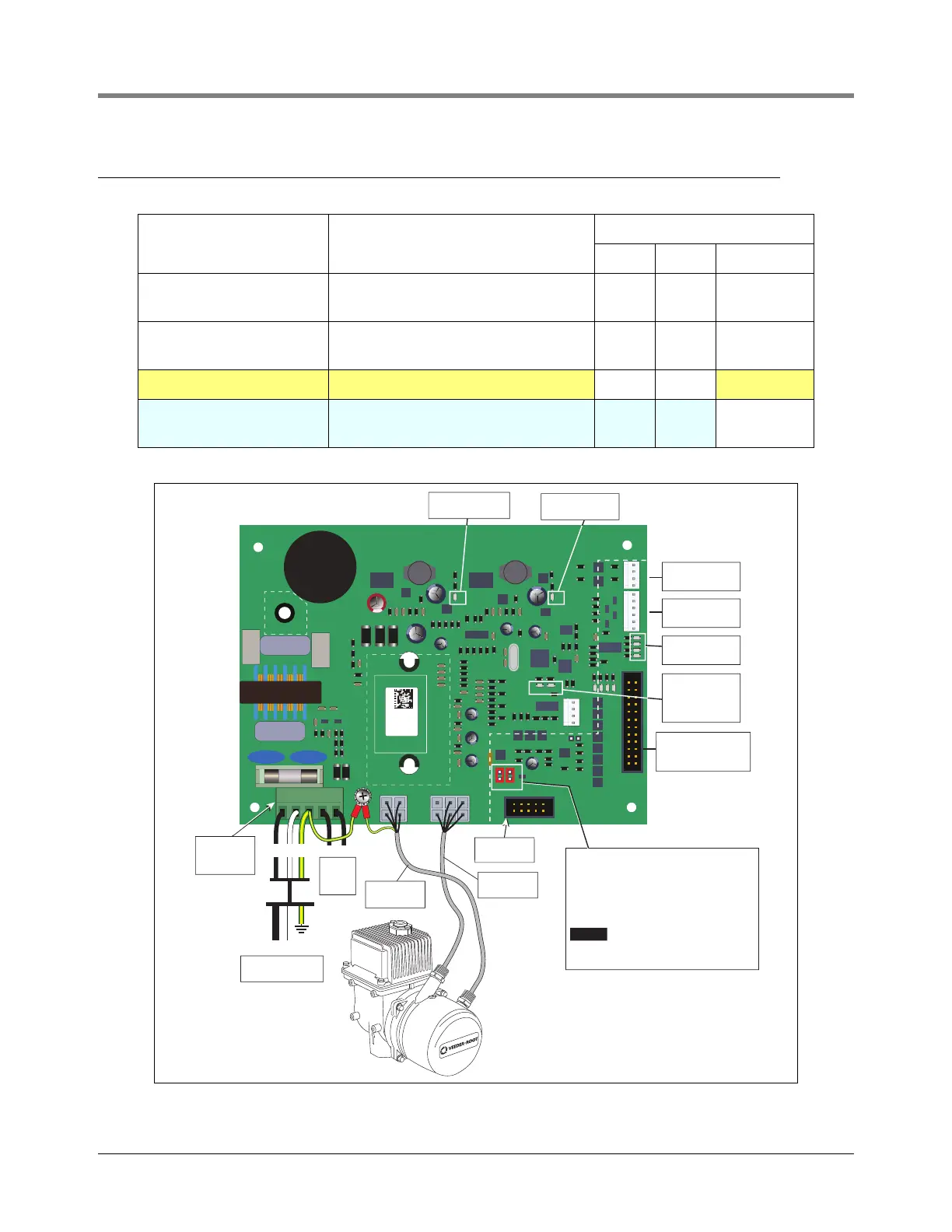

Figure 4. VaporTEK-3 Controller Board Connections

Configuration Type VaporTEK Controller Mode

Mode Selection

J1 J2 J3-PROG.

VaporTEK Basic

VaporTEK Plus

Two-speed system, high voltage hook sig-

nals are required

No No No

VaporTEK Enhanced

VaporTEK Ultra

Electronic signal of fuel flow required No No No

Board Programming Mode Power OFF/ON cycle required No No Yes

VaporTEK Enhanced

VaporTEK Ultra

VaporTEK - master mode with monitoring

system and re-regulation

Yes Yes No

VEEDER-ROOT

VAPORTEK-CONTROLLER

900890-001

Rev.C

P/N 141 031 916

S/N 0000586

DATE 49/2016

RoHS Compliant

PE

F1

PE

L N PE M1 M2

+ - AB SB AA SA EPV VALVE

MOTOR

POWER

MOTOR

SIGNAL

J3

V6

V3 V8

V1

X7

X6

X8

PROGRAM

J1

J2

X3X2

X1

X4

BR1

IC5

RS422

L1 N

L1 N

PE

High

Voltage

Inputs

AC - Main Power

110V - 230V

Main Power

Connector

X1

Motor Power

Cable

Motor Signal

Cable

To VaporTEK-3

Pulse Interface

Adapter Board - X8

Board Heartbeat

LED - V3

Motor/Board

Error LED - V8

Monitor Status

LEDs

External LED

Connector - X7

External EPV

Connector - X6

J1/J2 Jumper Setting - RS422 Serial

J1 and J2 need to be placed to establish

monitoring communication with re-

regulation using the X4 - RS422

interface.

NOTICE Do not place these jumpers if a

Master device like SK700-2 or Appolo

Calculator is connected to that interface!

5V Board Logic

Power LED - V6

15V Motion Chip

Power LED - V1

UNSAFE AREA

UNSAFE AREA

SAFE AREA

RS422 Serial

X4

M1 M2

Loading...

Loading...