A complete description of installation and deployment

of the terminating resistors is delivered with the con-

nector

.

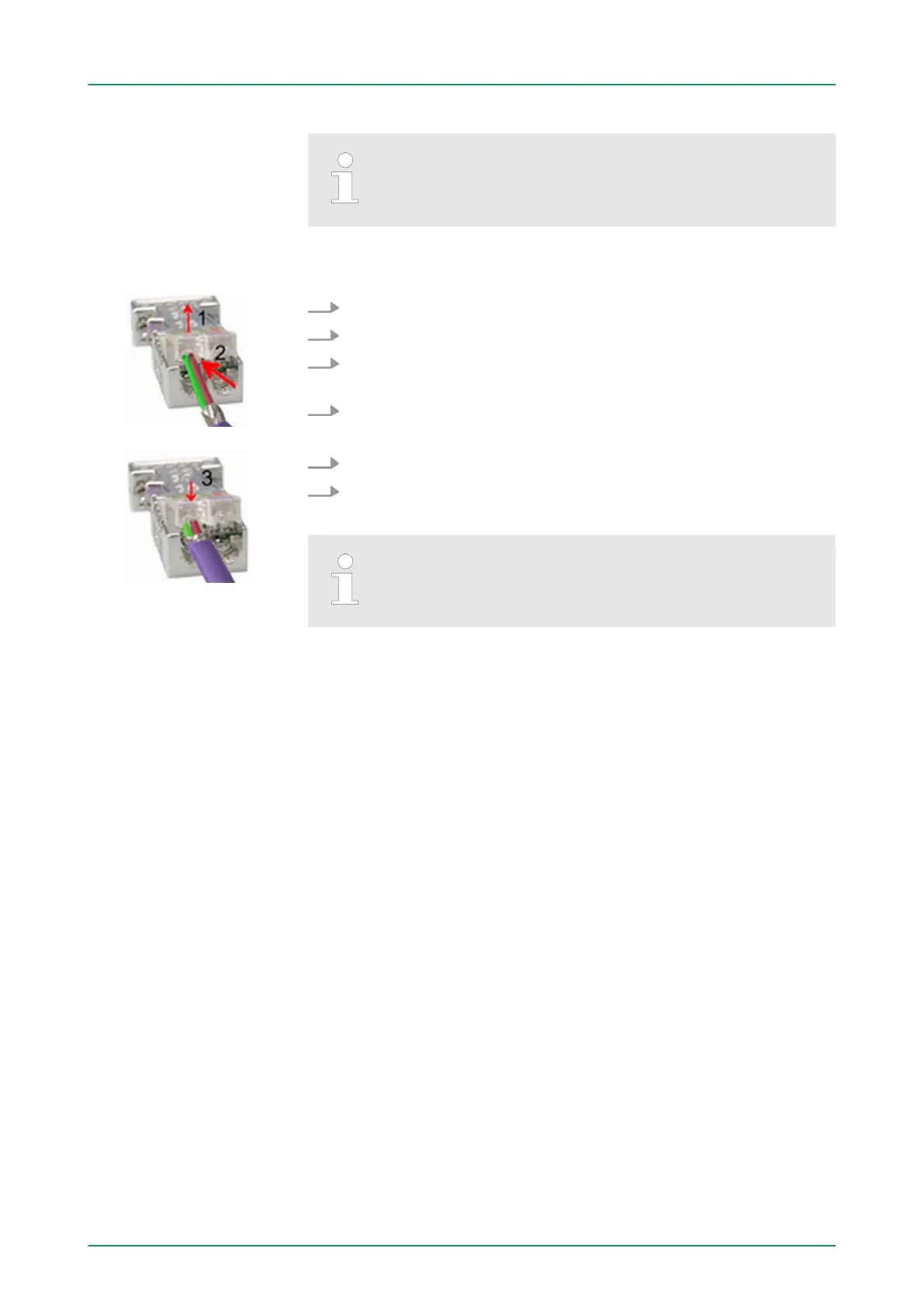

1. Loosen the screw

.

2. Lift contact-cover

.

3. Insert both wires into the ducts provided (watch for the correct

line colour as below!)

4. Please take care not to cause a short circuit between screen

and data lines!

5. Close the contact cover

.

6. T

ighten screw (max. tightening torque 0.08Nm).

The green line must be connected to A, the red line to

B!

8.7 Commissioning and Start-up behavior

In delivery the CPU is overall reset. The PROFIBUS part is deacti-

vated and its LEDs are of

f after Power ON.

The DP master can be served with bus parameters by means of a

hardware configuration. As soon as these are transferred the DP

master goes online with his bus parameter. This is shown by the RUN

LED. Now the DP master can be contacted via PROFIBUS by means

of his PROFIBUS address. In this state the CPU can be accessed via

PROFIBUS to get configuration and DP slave project.

If the master has received valid configuration data, he switches to

Data Exchange with the DP slaves. This is indicated by the DE-LED.

After PowerON respectively a receipt of a new hardware configuration

the configuration data and bus parameter were transferred to the DP

master. Dependent on the CPU state the following behavior is shown

by the DP master:

Assembly

Start-up on delivery

Online with bus param-

eter without slave

project

Slave configuration

CPU state controls DP

master

VIPA System 300S Deployment PROFIBUS communication

Commissioning and Start-up behavior

HB140 | CPU | 314-6CF03 | GB | 16-43 203

Loading...

Loading...