31

Cylinder head

Cylinder head, inspection

(12A-12)

1

Remove the cylinder head assembly, operations

12A-07.

2

Remove the thermostat housing.

3

Remove the seawater pump, operation 20A-06.

4

Remove the camshaft cover, operation 12A-01 and

the camshaft.

Remove the valve lifters and shims and place each

valve lifter and shim together in a numbered place,

so that they can be returned to their original posi-

tions.

5

Check the cylinder head for signs of gas or coolant

leakage.

6

Remove the valve springs and valves, operation

12A-08.

7

Clean the cylinder head surface. Clean the coolant

and lubrication channels. The water mantle can be

cleaned with a special solvent which must be used

according to the manufacturers instructions.

8

Check the cylinder head for leakage at the pressure

specified in the Workshop Manual “Technical Data”.

9

When the cylinder head is completely clean, it

should be checked for cracks. Carefully check the

areas around the valve seats and the holes for in-

jector nozzles.

10

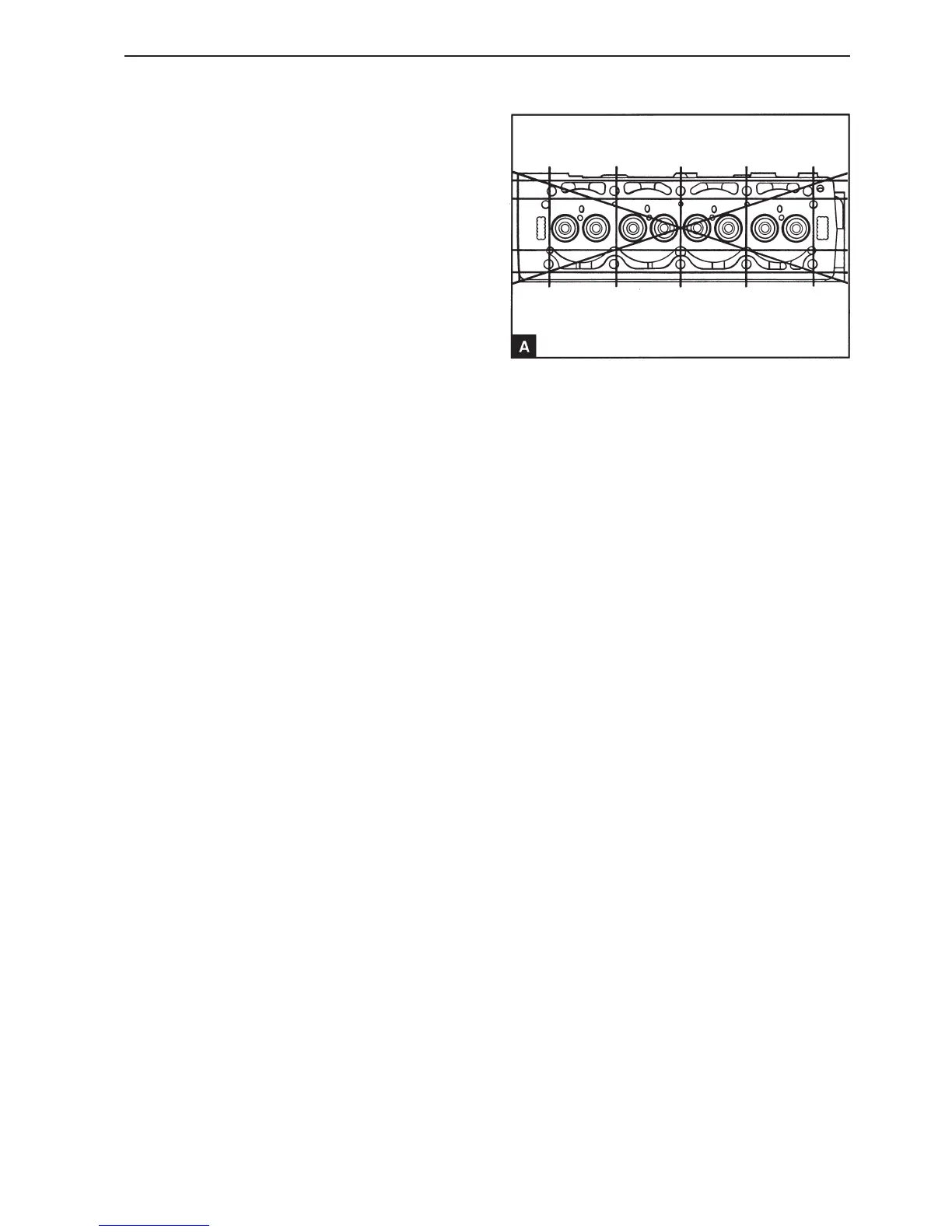

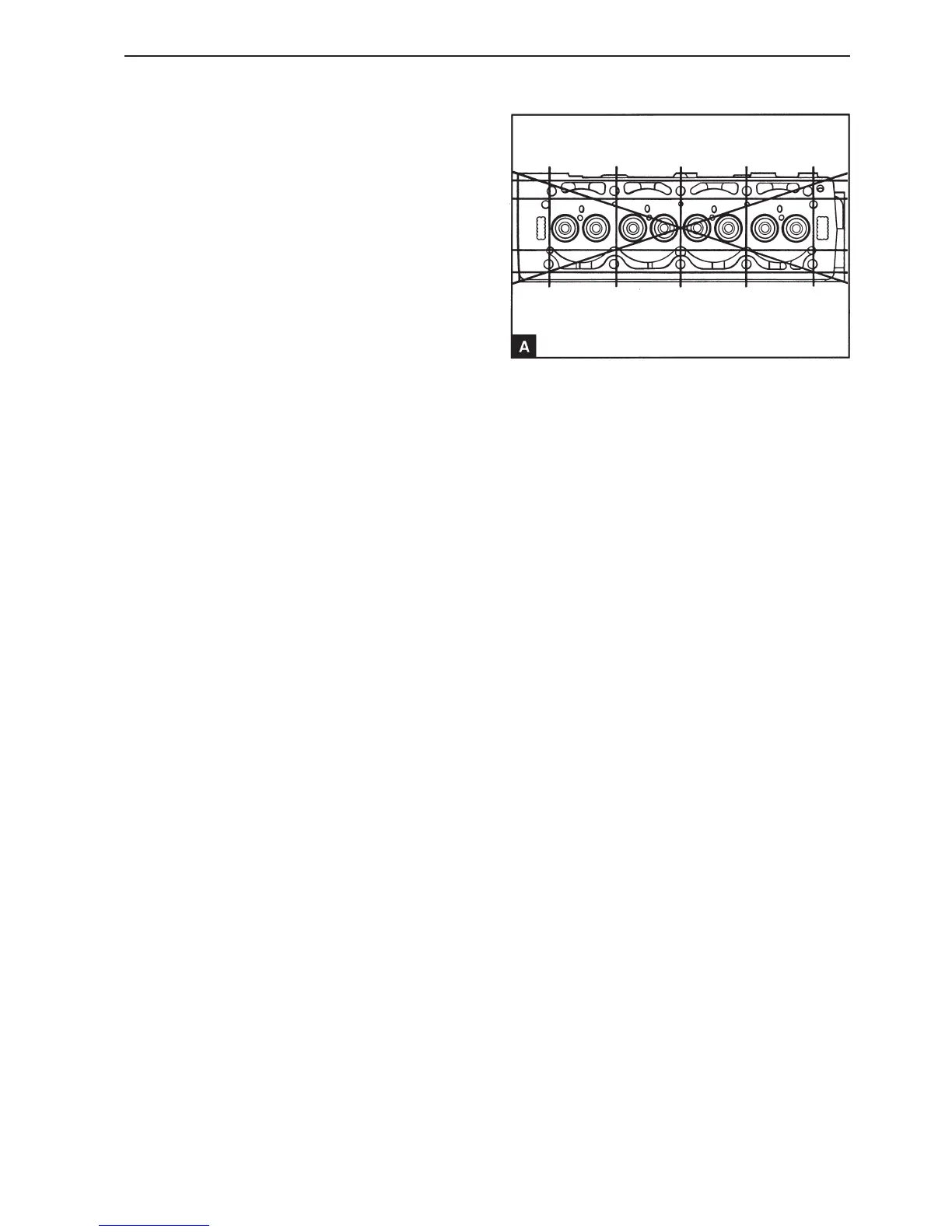

Use a straight edged ruler and a feeler gauge to

check the latitudinal, longitudinal and diagonal flat-

ness of the bottom surface of the cylinder head (A).

If deformation is greater than 0.10 mm the bottom

surface can be machined. Remove the minimum

amount of material and check that the cylinder head

height will not be less than 119.85 mm after the cyl-

inder head has been treated.

NOTE! After the cylinder head has been machined

the valve seats must be corrected to give the cor-

rect valve depth. It is recommended to use the mini-

mum value to allow for wear later.

11

Check the valve seats for damage and wear.

12

Before carrying out any work on the valve seats,

check that the valve guides are not worn, see

Workshop Manual “Technical Data”. If valve guide

wear is above the parameter values the valve

guides must be replaced, operation 12A-11.

13

If the damage is mild the valve and valve seat can

be lapped in. When the valve seats are lapped keep

the sealing area as thin as possible and ensure that

all lapping paste used on the valve and seat is re-

moved.

Loading...

Loading...